Why Proper Bearing Lubrication Matters: Types, Methods, and Maintenance Tips

This article explores the critical role of bearing lubrication in reducing friction and preventing failure. It covers the differences between grease and oil, proper application methods, common mistakes to avoid, and maintenance strategies to ensure industrial machinery operates efficiently.

Cylindrical Roller Bearings vs Needle Roller Bearings: A Detailed Comparison

This technical guide provides a side-by-side comparison of cylindrical vs needle roller bearings, analyzing their structural differences, load capacities, and speed limitations. It offers engineers and buyers practical advice on selecting the right bearing type to optimize machinery performance and space efficiency.

Angular Contact Ball Bearings: Features, Benefits, and Best Applications

This article explores the design, functionality, and benefits of angular contact ball bearings, highlighting their ability to handle combined loads in high-speed industrial applications like robotics and automotive systems.

Thin-Section Bearings: Advantages and Best Use-Cases in Space-Saving Machinery

This comprehensive guide examines the unique geometry and benefits of thin-section bearings, highlighting their ability to reduce weight and save space in advanced machinery. It covers specific design types, load capacities, and essential maintenance tips for optimal performance.

How to Read Bearing Codes: A Simple Guide for Engineers and Buyers

This practical bearing code guide breaks down the complex alphanumeric designations used by manufacturers. It explains how to interpret bearing types, bore sizes, and critical suffixes, helping engineers and buyers avoid costly errors during selection and procurement.

Electrically Insulated Bearings: Why They Matter for Motor Reliability

This article explains the critical role of insulated bearings for motors in preventing damage caused by stray electrical currents in modern drive systems. It covers the types of insulation, the mechanism of protection, and the long-term benefits for industrial maintenance.

Miniature Ball Bearings: Applications, Benefits, and How to Select the Right Size

This article explores the essential characteristics, benefits, and applications of miniature ball bearings, offering a detailed guide on selecting the correct specifications for high-speed and compact precision machinery.

A Complete Guide to Self-Aligning Ball Bearings for High-Precision Machinery

This guide explores the design and function of self-aligning ball bearings, highlighting their ability to accommodate angular misalignment in precision machinery. It covers load capacity, speed benefits, and selection criteria to help engineers ensure operational stability.

Ball Bearings vs Roller Bearings: What’s the Difference and Which One Should You Choose?

This guide analyzes the structural and functional distinctions between ball bearings and roller bearings, providing engineers and procurement teams with essential insights on load capacity, speed limits, and durability to ensure the correct selection for specific industrial applications.

Technical Guide to High Precision Ball Bearings for Industrial Use

SDTFL produces high precision ball bearings engineered for industrial applications requiring consistent performance, durability, and operational accuracy. These bearings support a wide range of mechanical systems across multiple sectors.

Miniature Angular Contact Ball Bearings: Precision and Performance in Compact Design

SDTFL miniature angular contact ball bearings are engineered for compact applications demanding high speed, accuracy, and durability. Designed with precision and advanced materials, they ensure superior performance in industrial, automotive, and precision instrument applications.

How Slewing Ring Bearings Support Tunnel Boring Machines and Dredgers

Slewing ring bearings provide vital support and smooth rotation for tunnel boring machines and dredgers, ensuring reliability under heavy loads.

Where Are Slewing Ring Bearings Used Today

Slewing ring bearings are used in cranes, wind turbines, medical scanners, robotics, and heavy machinery for smooth rotation and load support.

TFL’s High Precision Bearings: Accuracy, Reliability, and Customization

TFL’s High Precision Bearings meet P5 & P4 standards, offering superior accuracy, reliability, and expert Chinese craftsmanship for demanding industries.

Is Your Motor Bearing Noise Normal?

While all motor bearings make some noise, it’s crucial to distinguish normal, stable sounds from problematic ones. This article explains inherent bearing noises and highlights key indicators like sudden clicks, inconsistent tones, or irregular frequencies as warning signs of potential failure, emphasizing the importance of timely inspection.

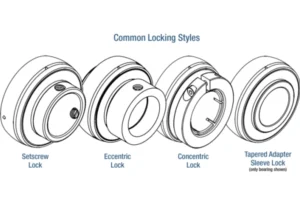

Why Do Bearing Housings on Shafts Have Different Locking Methods?

Selecting the correct bearing locking method is crucial for longevity and performance. Consider rotation, speed, vibration, and shaft tolerance to choose from set screw, eccentric collar, concentric clamp, or adapter sleeve locking, extending bearing life by up to 30%.