Simple Steps to Evaluate and Care for Roller Bearings

Assess roller bearings with simple checks, cleaning, and proper lubrication to prevent failure and extend equipment life. Follow these easy maintenance steps.

Assess roller bearings with simple checks, cleaning, and proper lubrication to prevent failure and extend equipment life. Follow these easy maintenance steps.

Split roller bearing offers faster installation and easier maintenance than one-piece roller bearing, making it ideal for hard-to-access or critical equipment.

Use this checklist to select roller bearing suppliers, covering quality, certifications, support, and pricing for reliable, long-lasting machine performance.

Roller bearings in linear guide systems cut downtime by 70% and lower maintenance costs, boosting assembly line reliability and equipment lifespan.

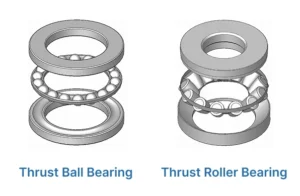

Thrust bearings and washers boost machine speed, load, and lifespan by up to 50% by reducing friction, wear, and heat for reliable, efficient operation.

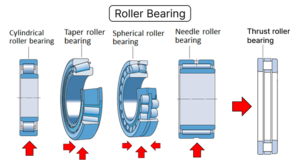

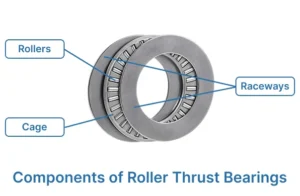

A roller thrust bearing supports heavy axial loads, reduces friction, and boosts machine life. Learn types, uses, and key tips for selection and care.

Compare roller bearing vs ball bearing to see which suits heavy loads or high speeds. Find key differences and best uses for your machinery needs.

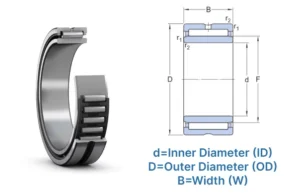

Match needle roller bearing sizes to your shaft and housing by measuring ID, OD, and width, then use a size chart for the best fit and performance.

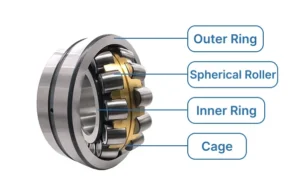

A spherical roller bearing uses barrel-shaped rollers to support heavy loads and self-align, reducing friction and handling shaft misalignment efficiently.

Tapered roller bearing design supports both radial and axial loads, making it ideal for automotive, industrial, and heavy machinery applications.

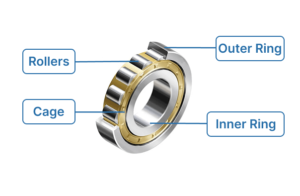

Cylindrical roller bearing structure supports heavy radial loads, offers high speed, and ensures durability for industrial, automotive, and machinery uses.

Caged Design in needle roller bearings offers smoother operation, higher speed, and less maintenance, while cageless types excel in heavy load capacity.

Roller bearings sealing structures protect against contaminants and retain lubricant, ensuring longer bearing life and reliable performance in various applications.

High precision ball bearings offer tighter tolerances, longer life, and lower vibration than standard types—worth the cost for demanding applications.

Insulated Ball Bearings 6310M/C3VL0241 block stray currents, preventing electrical damage and extending motor life in high-voltage industrial applications.

3D printing bearings enable custom designs, rapid prototyping, and cost savings, but face material limits. See trends, benefits, and industry adoption insights.