Free Industrial Bearing Interchange Tool Recommendation List – Latest Updates 2025

This article lists 10 free industrial bearing interchange tools and one paid tool. They can help you change your bearing’s brand.

This article lists 10 free industrial bearing interchange tools and one paid tool. They can help you change your bearing’s brand.

Traction motor insulated bearings prevent electrical damage in high-speed rail, ensuring safe, reliable operation and longer service life for traction motors.

Insulated bearings in VFD motors prevent electrical damage, boost reliability, and cut maintenance costs by reducing bearing failures and downtime.

Choose the right angular contact bearings for 5-axis CNC machines by matching load, speed, and precision needs to boost accuracy and extend machine life.

Compare single row cylindrical roller bearings structures, including NU, N, NJ, NF, NUP, and NH types, to select the right cylindrical roller bearings structure.

Needle Thrust Bearings offer high load capacity and compact design, enabling precision machinery to achieve greater reliability and efficiency in demanding fields.

Plastic roller bearings excel in automotive, food, medical, and marine industries, offering corrosion resistance, low maintenance, and lightweight performance.

Ever wondered what makes heavy equipment glide effortlessly? It’s often the humble roller ball caster! Dive into the mechanics of these small but mighty components that enable seamless multidirectional movement.

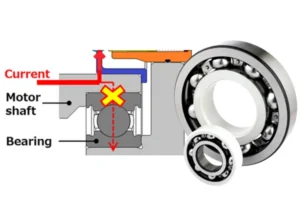

Electrically Insulated Bearings prevent bearing current corrosion in electric motors, ensuring longer service life and reducing costly downtime.

Coated insulated bearings feature a ceramic layer that blocks electrical currents, preventing bearing damage and extending machinery service life.

Compare 8 reliable roller bearing suppliers for quality, support, and fast delivery. Find trusted options for your next industrial or engineering project.

High-temperature failure in machinery bearings can halt harvests. See how a Brazilian farmer solved this issue and learn prevention strategies for your farm.

Essential roller bearing terms explained for beginners—covering parts, codes, and standards to help you choose, install, and maintain roller bearings.

Select the right heavy duty roller bearings by evaluating load, speed, environment, and material to ensure optimal performance in industrial applications.

Metal vs plastic roller bearings: Learn their differences, pros, cons, and ideal uses. Find out which bearing type is best for your machine. Order today!

Quality Certifications like ISO 9001, IATF 16949, and CE Marking ensure your bearings meet top safety, reliability, and compliance standards.