In industrial maintenance and equipment repair, bearing replacement is a routine yet critical task. When original equipment manufacturer (OEM) bearings are unavailable, discontinued, or impractical due to cost or lead time, engineers and procurement teams often turn to bearing crossover charts. A bearing crossover chart serves as a reference tool that helps match bearing models across different brands based on size, load rating, and performance characteristics. Understanding how these charts work and how to use them correctly is essential for maintaining equipment reliability and avoiding costly mistakes.

What Is a Bearing Crossover Chart

A bearing crossover chart, also known as a bearing cross-reference chart, is a technical reference that compares bearing part numbers from different manufacturers. These charts allow users to identify equivalent bearings that share the same dimensions, internal design, and load capacity, even though the part numbers differ by brand.

Because bearing manufacturers follow standardized dimensional systems such as ISO and ANSI, many bearings are interchangeable in theory. However, practical interchangeability depends on more than just size. A crossover chart helps bridge this gap by presenting equivalent bearing options that meet similar performance criteria.

Why Bearing Cross-Referencing Is Important

Bearing cross-referencing plays a vital role in minimizing downtime and controlling maintenance costs. In industries where equipment operates continuously, waiting for an OEM bearing can lead to significant production losses. Using a suitable replacement bearing from another brand allows operations to resume quickly without compromising performance.

Cross-referencing is also important for global supply chains. Different regions may favor different bearing brands, and availability can vary by market. A reliable crossover chart helps procurement teams source bearings efficiently while maintaining consistency in performance and quality.

How Bearing Crossover Charts Are Structured

Most bearing crossover charts are organized by bearing type and series. Common categories include cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and ball bearings. Within each category, bearings are listed according to their dimensional series, such as bore diameter, outer diameter, and width.

In addition to basic dimensions, some crossover charts include information about load ratings, cage materials, lubrication requirements, and internal clearance. These details are critical for ensuring that the replacement bearing performs as expected under operating conditions.

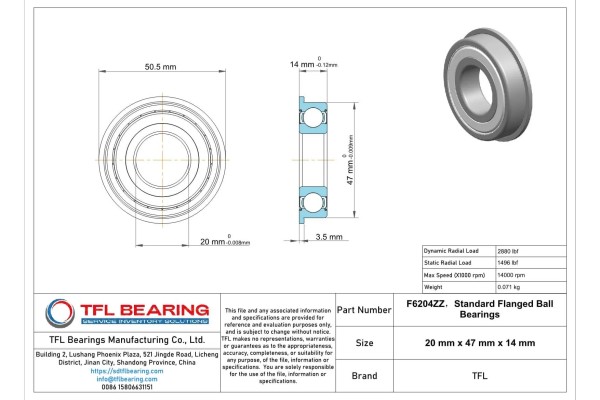

| Code | Component | Description |

|---|---|---|

| 6204 | Base Designation | Standard Deep Groove Ball Bearing (20x47x14mm) |

| ZZ | Shielding | Metal shields on both sides (Dust protection) |

| C3 | Internal Clearance | Clearance greater than Normal (For high speed/heat) |

| L2 | Lubrication | Specific grease type (e.g., Wide temp range) |

| PX1 | Tolerance | Special tolerance for precision applications |

Key Factors to Consider When Using a Crossover Chart

While bearing crossover charts are useful tools, they should not be used blindly. Several factors must be considered before selecting a replacement bearing.

Load capacity is one of the most important considerations. Even if two bearings share identical dimensions, their dynamic and static load ratings may differ due to variations in material quality or internal design. Speed rating is another factor, especially in high-speed applications where excessive heat or vibration can cause failure.

Internal clearance, sealing design, and cage construction also influence bearing performance. Differences in these features can affect lubrication behavior, noise levels, and service life. Therefore, users should always verify that the replacement bearing meets the specific requirements of the application.

Common Applications of Bearing Crossover Charts

Bearing crossover charts are widely used across industries such as manufacturing, mining, automotive, power generation, and material handling. In maintenance operations, technicians often rely on these charts to quickly identify replacement bearings during emergency repairs.

Original equipment manufacturers also use cross-referencing during design updates or supplier changes. By validating equivalent bearings across brands, OEMs can maintain flexibility in sourcing without redesigning components.

Risks of Incorrect Bearing Cross-Referencing

Improper use of bearing crossover charts can lead to serious operational issues. Selecting a bearing based solely on dimensions without considering load ratings or internal design may result in premature failure. In extreme cases, incorrect bearing selection can cause shaft damage, housing deformation, or safety hazards.

Another common risk is overlooking application-specific requirements such as temperature limits, contamination resistance, or lubrication methods. These factors are often optimized in OEM bearings and may vary across brands. Careful evaluation is essential to avoid unintended consequences.

Best Practices for Using Bearing Crossover Charts

To use bearing crossover charts effectively, it is important to treat them as a starting point rather than a final decision tool. Engineers should always cross-check technical specifications and consult manufacturer documentation before approving a replacement bearing.

Whenever possible, real operating conditions such as load, speed, and environment should be reviewed. In critical applications, testing or consultation with bearing specialists can further reduce risk. Keeping detailed maintenance records also helps validate the long-term performance of cross-referenced bearings.

OEM Replacement Bearings and Quality Considerations

Quality consistency is a major concern when replacing OEM bearings. While many manufacturers produce bearings that meet international standards, differences in manufacturing processes, materials, and quality control can affect performance.

High-quality replacement bearings are typically manufactured using premium bearing steel, advanced heat treatment, and precision grinding. These factors contribute to consistent load distribution and fatigue resistance. Technical guidance on OEM replacement and cross-brand bearing selection, such as the explanations provided by SDTFL Bearing, helps users understand the limitations and precautions involved in cross-referencing bearings.

Bearing Crossover Charts for Roller Bearings

Roller bearings are commonly cross-referenced due to their widespread use in heavy-duty applications. Cylindrical roller bearings, for example, are often interchangeable across brands within the same dimensional series. However, variations in cage design or roller profile can influence load capacity and speed performance.

Spherical and tapered roller bearings require even greater attention during cross-referencing because they often handle combined loads and misalignment. Ensuring that the replacement bearing can accommodate these conditions is critical for safe operation.

Digital Tools and Modern Cross-Referencing

Advancements in digital technology have improved the accuracy and accessibility of bearing crossover information. Many manufacturers now provide online cross-reference tools that allow users to search by OEM part number and instantly view compatible alternatives.

These tools often include updated technical data and warnings about non-equivalent substitutions. Digital platforms reduce the risk of human error and make it easier to keep cross-reference information current as product lines evolve.

When Not to Use a Bearing Crossover Chart

There are situations where bearing cross-referencing may not be appropriate. Highly specialized applications, such as aerospace systems or safety-critical machinery, often require OEM-specific bearings that meet strict certification requirements. In such cases, using a non-OEM bearing may void warranties or violate regulatory standards.

Similarly, equipment operating under extreme conditions such as very high speeds, temperatures, or contamination levels may require custom bearing solutions that cannot be safely substituted using standard crossover charts.

Importance of Technical Verification

Technical verification is the final and most important step in bearing cross-referencing. This involves comparing detailed specifications, reviewing application requirements, and, if necessary, consulting bearing engineers. Verification ensures that the selected replacement bearing will deliver reliable performance over its intended service life.

In complex systems, even small differences in bearing design can have significant effects. Therefore, a cautious and methodical approach to using bearing crossover charts is essential for maintaining operational integrity.

Conclusion

Bearing crossover charts are valuable tools for identifying OEM replacement bearings across different brands, helping industries reduce downtime and improve sourcing flexibility. When used correctly, these charts enable efficient maintenance and cost-effective equipment operation. However, successful cross-referencing requires more than matching dimensions. Load ratings, operating conditions, and quality factors must all be carefully evaluated.

By understanding how bearing crossover charts work and applying best practices in verification and selection, engineers and maintenance professionals can confidently identify suitable replacement bearings while safeguarding equipment performance and reliability.

Unsure About Your Replacement Choice?

Using a Bearing Crossover Chart is a great starting point, but ensuring the internal design and load ratings match is critical to avoiding downtime. At SDTFL Bearings, we don’t just sell part numbers; we verify performance.

Whether you need to cross-reference a discontinued model or find a cost-effective alternative for heavy-duty applications, our engineering team provides accurate conversions that guarantee reliability.

Access Our Cross-Reference Data

Contact us for a free technical consultation:

- 📧 Email: info@sdtflbearing.com

- 📞 Phone: +86 158 0663 1151

Related Resources:

Guide: Bearing Cross Reference Tool for Engineers

Cautions on OEM Replacement & Cross-Brand Models