As modern machinery becomes smaller, faster, and more precise, the demand for compact mechanical components has increased significantly. Bearings are no exception. In applications where space is limited but performance requirements remain high, miniature ball bearings play a critical role. These small yet highly engineered components enable smooth motion, reduced friction, and reliable operation in compact systems across a wide range of industries.

Miniature ball bearings are commonly used in precision devices, automation systems, medical equipment, and high-speed instruments. Selecting the correct miniature bearing is essential, as even slight mismatches in size, load capacity, or speed rating can impact performance and service life.

What Are Miniature Ball Bearings

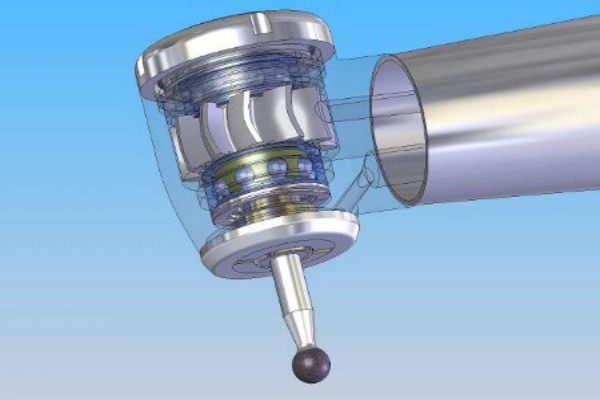

Miniature ball bearings are rolling-element bearings with a small-bore diameter, typically less than 10 millimeters. Despite their compact size, they function in the same way as standard ball bearings, using spherical balls positioned between the inner and outer raceways to reduce friction and support rotation.

General Characteristics of Miniature Ball Bearings

| Feature | Description |

| Typical Bore Diameter | Less than 10 mm |

| Rolling Element | Steel or ceramic balls |

| Contact Type | Point contact |

| Load Type | Primarily radial, limited axial |

| Speed Capability | High |

| Common Designs | Deep groove, flanged, sealed, shielded |

Popular Miniature Bearing Series & Sizes

To help you identify the right component, here is a list of the most commonly requested miniature bearing series we manufacture:

- 600 Series (Metric): 603, 604, 605, 606, 607, 608, 609

- 620 Series (Metric): 623, 624, 625, 626, 627, 628, 629

- 680/690 Series (Thin Section): 681 through 689, 691 through 699

- MR Series (Metric Open/Shielded): MR52, MR63, MR74, MR85, MR106, MR128

- Inch Series (R Series): R2, R3, R4, R6, R8

Precision sizing guaranteed. Don’t risk misalignment. Verify your dimensions with our extensive inventory list. [Check Stock Availability] for these specific models now.

Key Design Characteristics of Miniature Ball Bearings

Miniature ball bearings are manufactured with extremely tight tolerances to ensure accuracy and stability. Their raceways are precisely ground to minimize vibration and ensure uniform ball movement. Lightweight cages are often used to maintain balance and support high-speed operation.

Common Design Options

| Design Feature | Purpose |

| Flanged Outer Ring | Simplifies axial positioning |

| Shields | Protect against dust and debris |

| Seals | Prevent contamination and retain lubrication |

| Stainless Steel Material | Corrosion resistance |

| Ceramic Balls | Higher speed and lower friction |

Custom design requirements? Whether you need flanged options or specific seal types, our manufacturing facility can tailor solutions to your specs. [View our Product Catalog] to see our design capabilities.

Benefits of Using Miniature Ball Bearings

One of the primary advantages of miniature ball bearings is their ability to deliver high performance in extremely limited spaces. They allow engineers to design smaller, lighter machines without sacrificing rotational efficiency or precision.

Miniature ball bearings also generate low noise and vibration, making them ideal for sensitive applications. Their low-friction design supports energy efficiency and reduces heat buildup, contributing to a longer service life.

Load Capacity and Speed Performance

Miniature ball bearings are designed for light to moderate loads and excel in high-speed environments. Load capacity depends on bearing size, material, internal clearance, and lubrication.

Load and Speed Comparison

| Parameter | Miniature Ball Bearings | Standard Ball Bearings |

| Radial Load Capacity | Low to moderate | Moderate |

| Axial Load Capacity | Limited | Moderate |

| Speed Capability | Very high | High |

| Friction Level | Very low | Low |

| Typical Use | Compact precision systems | General machinery |

Ensure peak performance. Our technical team can assist you in calculating the exact load and speed ratings required for your application. [Email our experts] at info@sdtflbearing.com for support.

Typical Applications of Miniature Ball Bearings

Miniature ball bearings are used in industries where compact size and precision are critical. Their versatility allows them to perform reliably in both commercial and industrial equipment.

Industry Applications

| Industry | Application Examples |

| Medical | Dental tools, diagnostic devices, surgical instruments |

| Automation | Robotics, sensors, small actuators |

| Electronics | Cameras, printers, optical devices |

| Aerospace | Control systems, instrumentation |

| Automotive | Small motors, auxiliary systems |

Miniature Ball Bearings in High-Speed Machinery

High-speed machinery places demanding requirements on bearing stability and lubrication. Miniature ball bearings are well-suited for these applications due to their low friction and consistent rotational behavior.

Factors Affecting High-Speed Performance

| Factor | Impact on Performance |

| Cage Material | Influences stability at high RPM |

| Lubrication Type | Controls heat and wear |

| Internal Clearance | Affects temperature tolerance |

| Bearing Precision Class | Determines rotational accuracy |

Material Options and Environmental Considerations

Material selection plays a crucial role in bearing performance and longevity, especially in challenging environments.

Material Selection Guide

| Material | Advantages | Typical Applications |

| Chrome Steel | High strength, cost-effective | General machinery |

| Stainless Steel | Corrosion resistant | Medical, food equipment |

| Ceramic | High speed, low friction | Precision instruments |

| Hybrid (Steel + Ceramic) | Balanced performance | High-speed systems |

How to Select the Right Size of Miniature Ball Bearings

Choosing the correct size requires careful evaluation of bore diameter, outer diameter, width, load, and speed. Even small dimensional errors can lead to misalignment or premature failure.

Key Selection Parameters

| Parameter | Why It Matters |

| Bore Diameter | Must match shaft size |

| Outer Diameter | Must fit housing |

| Width | Affects load distribution |

| Load Rating | Prevents overload failure |

| Speed Rating | Ensures safe operation |

| Sealing Type | Protects against contamination |

Installation and Maintenance Best Practices

Due to their small size, miniature ball bearings must be installed carefully using appropriate tools. Excessive force or contamination during installation can significantly reduce bearing life. Sealed bearings require minimal maintenance, while open bearings may need periodic lubrication depending on operating conditions.

Common Mistakes to Avoid

Incorrect sizing, inadequate lubrication, and exposure to contaminants are common causes of premature failure. Overloading miniature ball bearings beyond their design limits is another frequent issue. Proper selection and handling are essential for reliable performance.

Miniature ball bearings are essential components in compact and high-speed machinery. Their ability to deliver precise, low-friction motion in confined spaces makes them indispensable across many industries. By understanding their characteristics, benefits, applications, and selection criteria, engineers and buyers can choose the right miniature ball bearings to ensure efficiency, reliability, and long-term performance.

Technical support available. Beyond manufacturing, SDTFL Bearings provides installation guidance to ensure maximum service life. [Contact our Support Team] if you are experiencing premature failures.

Ready to enhance your machinery with high-precision miniature bearings?

At SDTFL Bearings, we pride ourselves on delivering factory-direct quality with the precision your applications demand. Whether you need standard 600 series models or custom ceramic hybrid solutions, we have the manufacturing capability to support your business.

Take the next step towards reliable performance:

- Contact Us directly for a personalized consultation.

- Email your specifications to info@sdtflbearing.com.

- Call Us at +86 15806631151 for immediate assistance.

Don’t compromise on quality—let SDTFL Bearings be your trusted partner in precision motion.