For manufacturers, component suppliers, and bulk purchasers in the heavy machinery industry, selecting the right slewing bearing is a critical strategic decision. These components, often referred to as slewing rings or turntable bearings, are the backbone of any equipment requiring rotational motion and robust support.

But a key choice often arises during the design and procurement phase: should you opt for an internal gear or an external gear slewing bearing? This article will delve into the specifics of both types, helping you navigate the selection process with confidence.

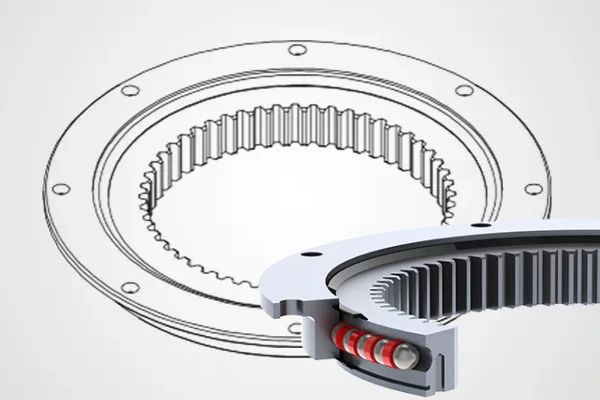

Internal Gear Slewing Bearing

Structure

An internal gear slewing bearing has gear teeth inside the inner ring. The outer ring is smooth and does not have teeth. The inner ring connects right to the drive part. Engineers pick this type for small machines. The gear is safe inside the bearing, so dust and dirt stay out. Balls or rollers move between the two rings. This design lets the bearing fit in small spaces where external gears cannot fit.

Advantages

Internal gear slewing bearings have many good points. The gear teeth are inside, so they stay clean and last longer. Machines with these bearings are quieter because the gear is covered. The design keeps the gear safe from rough places, so you do not need to fix it often. These bearings help keep oil inside, so they last longer. The small size saves space and works well for small machines.

Tip: Internal gear slewing bearings are great when space is tight and you need to keep out dust.

Disadvantages

Books and guides say there are some bad points too. If the load is not even, the races can bend and not last long. You must use the right oil, or the bearing can get damaged. Heavy loads make the bearing wear out faster. If the bearing turns slow, it can get small chips and pits. If the heat treatment is not done right, the bearing can break early. If there is too much play, the bearing can get loose and stop working. Tiny cracks from heat can grow and break the bearing. Engineers must make sure the bearing is set up right to stop problems.

Common Industrial Applications

- Aerial platforms

- Wind turbines

- Medical machinery

- Automation systems

For B2B customers with needs for sealed, compact, and quiet operation, internal gear slewing bearings are an optimal choice.

External Gear Slewing Bearing

Structure

An external gear slewing bearing has gear teeth on the outside ring. The gear is open, so it is easy to connect to other parts. Engineers use this type for big machines. Balls or rollers sit between the rings and help hold heavy things. The outside gear can be bigger, so more teeth fit around it. This helps the bearing handle more turning force and heavier loads.

Advantages

External gear slewing bearings have many good points in factories.

- The open gear is easy to check and fix.

- A bigger gear and more teeth help move heavy things with less effort.

- These bearings spread weight well, so they last longer.

- They help machines move in a very exact way.

- The design is great for slow, strong machines like cranes and wind turbines.

- For big sizes, these bearings cost less than internal gear types.

- If one part breaks, the gear system keeps working and stays safe.

Disadvantages

External gear slewing bearings have some problems too. The open gear teeth can get dirty or wet, so you must clean them often. Engineers need to check the gear a lot to stop damage. The open design means you must add oil and protect it from bad weather. In dirty places, the gear can wear out faster. Machines with these bearings should have covers or seals to keep the gear safe.

Common Industrial Applications

- Excavators

- Port and ship cranes

- Drilling rigs

- Construction machinery

If your equipment demands robust torque handling and frequent maintenance access, external gear slewing bearings are the go-to solution.

Key Differences: External Gear vs Internal Gear

| Comparison Item | Internal Gear | External Gear |

|---|---|---|

| Gear Location | Inner ring | Outer ring |

| Space Efficiency | High | Moderate |

| Installation | Relatively complex | Easier |

| Maintenance Access | Limited access | Easy access |

| Exposure | Well protected | High exposure |

| Torque Output | Medium | High |

| Typical Clients | Medical, automation, energy manufacturers | Construction machinery, building equipment manufacturers |

How to Choose Between Internal and External Gear Slewing Rings?

For purchasing managers and engineering teams, your decision should be driven by the specific needs of your application. Consider the following:

- Application Environment: Is the equipment operating in a harsh, dusty, or corrosive environment? If so, the protected design of an internal gear bearing may be your best bet to prevent premature wear and ensure the long-term reliability of your final product.

- Space and Aesthetics: Does the equipment have tight space constraints or a design that benefits from a clean outer profile? An internal gear bearing is more compact and aesthetically pleasing.

- Required Torque and Load: Does the application require very high torque transfer or support extremely heavy loads? An external gear bearing might be more suitable due to its robust nature, ensuring the stability and safety of your machine.

- Maintenance Protocol: Is your maintenance schedule based on easy access and quick inspections? External gears are the clear winner here, reducing service time and cost.

To help you with your decision, here’s a quick guide:

| Application | Recommended Gear Type | Key Benefit | Type |

|---|---|---|---|

| Excavators, Tunneling Machines | Internal Gear | Environmental Protection: The enclosed design prevents dirt and debris from damaging the gears, extending component life. | Single-Row Ball or Cross-Roller |

| Mobile Cranes, Truck Cranes | External Gear | High Torque & Easy Maintenance: Easily accessible for inspection and lubrication, suitable for demanding lifting operations. | Single-Row Ball or Double-Row Ball |

| Wind Turbines, Solar Trackers | External Gear | Robustness & Load Capacity: Capable of handling significant overturning moments and continuous operation in demanding conditions. | Double-Row Ball or Three-Row Roller |

| Medical Equipment, Radar Platforms | Internal Gear | Compactness & Precision: Offers a smaller footprint and a clean, protected drive system for high-precision motion. | Four-Point Contact Ball or Crossed Roller |

TFL Bearings: Factory-Direct Custom Solutions for Slewing Rings

TFL Bearings is a manufacturer-direct supplier with full in-house capabilities for designing, machining, heat-treating, and testing slewing bearings. Whether you need internal gear, external gear, or non-geared slewing rings, we provide a full one-stop solution.

Our commitment to quality begins in our own manufacturing facility. We perform high-frequency quenching or overall tempering on the raceways and gear teeth of our slewing rings to ensure maximum hardness and durability. Before leaving our factory, every single slewing bearing undergoes a rigorous multi-point inspection. Our quality control standards strictly reference JB/T 2300-2011 or meet our customers’ specific requirements.

Comprehensive inspection process includes:

- Gear surface runout and meshing checks

- Hardness testing

- Coating and corrosion resistance inspection

- Smoothness of rotation under no load

- Dust seal integrity verification

By combining advanced manufacturing techniques with stringent quality control, TFL Bearings provides reliable, long-lasting slewing rings that are engineered to excel in your most demanding applications, helping you reduce procurement costs and ensure the efficiency of your production line.

Conclusion

Whether you’re designing next-generation wind turbines or sourcing components for heavy machinery, choosing the right slewing bearing type can make or break the performance of your product.

TFL Bearings provides reliable, factory-direct slewing ring solutions that combine engineering expertise, cost efficiency, and consistent quality—tailored for industrial buyers like you.

Get in touch with our engineers today and let TFL help you choose the perfect slewing ring for your next project.

FAQ

What is the main difference between internal gear and external gear slewing bearings?

Internal gear slewing bearings have teeth on the inside ring. External gear slewing bearings have teeth on the outside ring. This changes how each bearing fits in machines. It also changes how well each one handles weight.

Which type offers better protection against dust and dirt?

Internal gear slewing bearings protect better from dust and dirt. The teeth are inside the ring, so dirt cannot get in easily. External gear slewing bearings have teeth outside, so they get dirty faster. They need more cleaning and care.

Which slewing bearing is easier to inspect and maintain?

External gear slewing bearings are easier to check and fix. The teeth are outside, so you can see and reach them quickly. Internal gear slewing bearings are harder to check because the teeth are inside.

When should engineers choose internal gear slewing bearings?

Engineers pick internal gear slewing bearings when space is small. They also use them when it is important to keep out dirt. These bearings work well in places with lots of dust or dirt.

What applications suit external gear slewing bearings best?

External gear slewing bearings are good for big, heavy machines. They work well in cranes and wind turbines. These bearings can hold a lot of weight and are easy to fix. Their design helps machines move strong and exactly in factories.