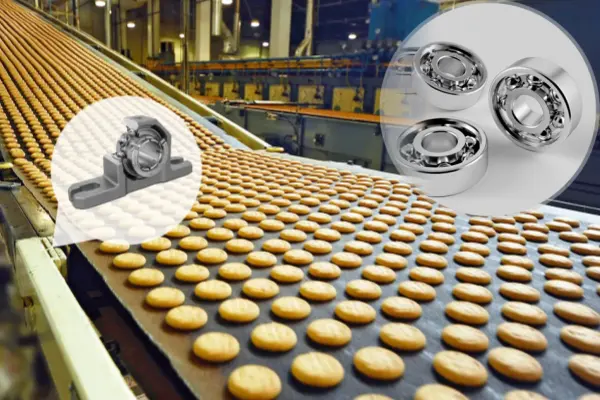

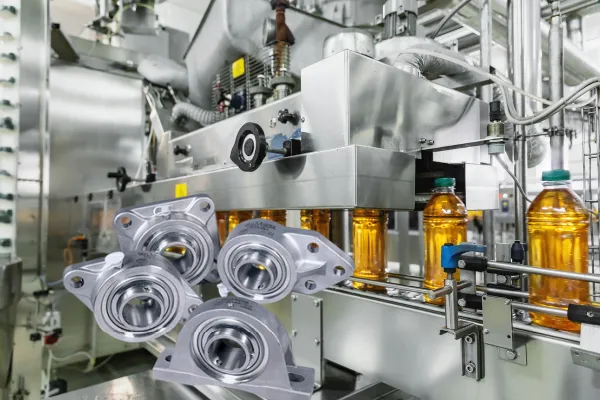

If you are a procurement manager in the food and beverage industry, ensuring your equipment stays clean and safe is a top priority—especially critical components like bearings. High-quality stainless steel bearings are the ideal solution. They resist rust, withstand strong cleaning chemicals, and provide reliable safety in food processing. Their sealed design prevents water and dirt from entering, reducing the risk of contamination.

For food production companies, the quality of bearings directly impacts both safety and efficiency. Only stainless steel bearings can meet the strict hygiene and reliability standards required for large-scale food manufacturing. If your company is planning to purchase bearings in bulk or make large-scale procurement, choosing stainless steel bearings ensures a safe, dependable, and cost-effective solution for your production line.

Key Takeaways

- Stainless steel bearings do not rust or corrode. This makes machines easy to clean. It also keeps food processing safe. Smooth surfaces and special seals block dirt, water, and bacteria. This helps stop contamination and keeps food pure. These bearings can handle strong cleaning chemicals. They also work well in tough conditions. They last longer and help machines run more. Using food-grade lubricants and seals keeps food safe. It does not change the taste or safety of food. It also makes machines work better. Stainless steel bearings help food plants follow safety rules. They also save money by cutting down on repairs and stops.

Hygiene and Corrosion Resistance

Smooth Surfaces for Easy Cleaning

Stainless steel bearings are important in food factories. They help keep food safe and clean. Their smooth surfaces do not let bacteria hide. This makes cleaning much easier for workers. Food rules from groups like the American 3-A Sanitary Standards and the European Hygienic Engineering and Design Group say all food contact surfaces must be very smooth. The surface roughness should be Ra = 0.8 µm or less. This smoothness stops germs from growing and helps keep things clean.

A smooth, non-porous surface does not soak up liquids or dirt. This keeps germs on top, so cleaners can wash them away. Stainless steel bearings do not stain or rust. Workers can clean them with hot, soapy water and a soft cloth. Because they do not corrode, the surface stays smooth and easy to clean, even after many washes.

- Stainless steel’s non-porous nature:

- Stops bacteria from hiding in cracks.

- Makes cleaning easy and complete.

- Lowers the chance of germs coming back.

Food plants use these features to keep machines safe for food.

Withstanding Harsh Cleaning Agents

Food factories use strong cleaners and high-pressure water to clean machines. Stainless steel bearings can handle these tough chemicals. Makers use martensitic stainless steel (AISI 440C) and austenitic stainless steel (AISI 302 or 304) because they do not rust easily. These metals make a shield that protects the bearings from water, salt, and cleaners.

- Common cleaning agents in food processing include:

- Chlorine-based disinfectants

- Quaternary ammonium compounds

- Acidic and alkaline cleaners

- High-temperature water

Stainless steel bearings also use food-grade solid lubricants and special seals. These parts keep water and chemicals out of the bearing. Extra covers and coatings like nickel or PTFE give more protection. This helps bearings last through many cleanings without breaking.

But even stainless steel can have problems. Too much chloride or biocide, rough scrubbing, and high heat can cause damage. Keeping the surface smooth and not using rough cleaning helps the bearing stay strong. Stainless steel bearings with solid lubrication last longer than other types. They do not wash out easily, so they are less likely to fail during cleaning.

Preventing Contamination and Product Purity

Food plants must keep food safe and clean. Stainless steel bearings help stop contamination. They keep food pure. These bearings block things like water, rust, leaks, and bacteria. Their smooth surfaces and strong build make them great for food machines.

Non-Toxic and Non-Reactive Materials

Stainless steel bearings use safe materials. These do not react with food or cleaners. This keeps food safe and pure. The materials do not change the taste or smell of food. They do not add anything harmful. Food safety rules say these materials must meet strict standards. The table below lists some important certifications and what they mean:

| Certification/Standard | Description | Relevance to Food Contact Safety |

|---|---|---|

| FDA (Food and Drug Administration) | Needs stainless steel with at least 16% chromium for corrosion resistance | Makes sure stainless steel is safe and does not rust for food contact |

| NSF (National Sanitation Foundation) | Checks that equipment is clean and meets FDA rules | Shows the design is clean and follows food safety laws |

| ASTM International (e.g., ASTM A240/A240M-22a) | Sets rules for stainless steel, including chromium and chromium-nickel alloys | Tells if the material is good and safe for food use |

| ANSI (American National Standards Institute) (e.g., ANSI 2-2022) | Sets basic rules for food safety and clean equipment | Makes sure the design and build are safe and clean |

Stainless steel bearings with these standards do not rust or break down. They stay safe when touching food or cleaners. This keeps food pure and free from bad chemicals.

Note: Stainless steel bearings with these certifications help food plants follow FDA, USDA, HACCP, and HARPC food safety rules.

Specialized Sealing and Lubrication

Seals and lubricants are very important too. They keep out water, dirt, and cleaners. Good seals stop bacteria and dirt from getting inside. Food-grade lubricants and greases are safe if they touch food. These do not change taste or smell. They do not hurt people.

- Common ways food machines get dirty:

- Water gets into the bearing

- Rust from metal

- Leaks from grease

- Broken seals

- Bacteria or dirt in small spaces

Stainless steel bearings use special seals to stop these problems. Some seals use a winding path to keep out dirt and water. Some use Teflon (PTFE) to fight chemicals and lower friction. Magnetic seals keep out metal bits. Stainless steel shields, spinning flingers, and rubber lips work together to block threats. These parts help keep grease inside and block outside dangers.

Food-grade lubricants like H1 Quincal Syn FG Grease and H1 Silicone Spray meet NSF H1, Kosher, and Halal rules. These greases work well with stainless steel bearings. They fight water and heat. They last longer and need less care. Some plants use sealed for life bearings. These come with food-grade grease and do not need more. This lowers the risk of getting food dirty by mistake.

Tip: Using the right seals and grease helps bearings last longer and keeps food safe.

Stainless steel bearings with good seals and food-grade grease protect food from dirt. They help food plants keep food pure and safe.

Stainless Steel Bearings in the Food Processing Industry

Compliance with Food Safety Standards

Food factories must follow many rules to keep food safe. Stainless steel bearings help companies meet these rules. These bearings use special metals like AISI 440C and X65Cr13. These metals do not rust and are safe for food. They meet FDA 21 CFR and EU Regulation (EC) No 1935/2004. This means they do not put bad chemicals in food.

- Stainless steel bearings use food-grade lubricants. These lubricants, like H1, H2, and H3, are safe if they touch food.

- Solid lubrication, like solid grease or oil, keeps bearings working well. It stops leaks and keeps water out.

- Special seals keep dirt and water away. The seals also meet FDA, EU, and NSF rules.

Stainless steel bearings help food companies pass safety checks. They help stop contamination and make it easier to follow food safety laws.

Supporting Equipment Reliability

Food factories need machines that work all the time. Stainless steel bearings help machines work longer without breaking. These bearings do not rust and block dirt and water. They help machines run longer and break less often.

Stainless steel bearings use strong designs and materials. Some have ceramic balls in them. These bearings last longer and need less fixing. Smooth surfaces make cleaning easy and stop germs from growing. Good housing, like cast stainless steel or special plastics, gives more protection.

The table below shows how stainless steel bearings help a milk plant:

| Aspect | Previous Bearings | Stainless Steel Bearings with Life-Lube® Combination |

|---|---|---|

| Application | Milk processing plant conveyor | Same |

| Bearing Replacement Interval | Every 10 weeks | Over 1 year |

| Downtime per Replacement | 3 hours | None |

| Maintenance Effort | 2 fitters × 3 hours, 5 times/year | None |

| Lost Production Cost | 3 hours downtime × 2/year | None |

| Additional Parts Replaced | 2 shafts per year | None |

| Corrosion Resistance | Not specified | High (Martensitic stainless steel) |

| Lubrication | Difficult, required re-lubrication | Molded-Oil solid lubricant, no re-lubrication needed |

| Housing Material | Not specified | Silver-Lube® polymer housing, paint-free, contamination resistant |

| Total Annual Cost Savings | N/A | Approximately $14,195 |

This case shows why bearings matter in food factories. Stainless steel bearings help stop failures and save money. They help food factories keep machines running and avoid costly stops.

Durability and Operational Efficiency

Performance Under Heavy Loads

Stainless steel bearings work well in food plants. They can handle heavy loads and help machines run smoothly. Engineers tested AISI 440C stainless steel bearings in labs. They put heavy weight on them at different speeds. Bearings without coating broke after about 40 hours. Bearings with SlipCoat lasted 6,000 hours with no damage. This means they are stronger and last longer, even with little oil.

Tests in real food factories showed the same thing. SlipCoat bearings worked well under heavy loads. Ceramic rings lasted longer than plain steel but broke after 200 hours. SlipCoat bearings did the best in tough places.

Bearings made from 440 stainless steel with 304 housings do not rust. Silicone seals and steel shields keep out water and dirt. These parts help bearings stay strong in hard factory jobs.

Reducing Downtime and Maintenance

Food plants need machines that do not stop working. Stainless steel bearings help lower downtime and save money on repairs. Many factories used to change bearings every few weeks because they broke. For example, a potato chip plant lost $25,000 every hour the machines stopped. After using MicroPoly filled bearings, the plant ran for two years with no problems. This saved about $660,000 each year.

Other factories, like fish canning plants, saved money too. Bearings lasted a whole season, so they spent less on new parts and work. Guide rollers for fish saws used to break every month. With better bearings, they lasted three or four months, so machines stopped less.

A snack food company used Life-Lube stainless steel bearings. After one year, the machines had no problems. The company saved money on repairs and lost time. These stories show stainless steel bearings are reliable and work well. They help food plants save money and keep machines running longer.

Stainless steel bearings help food plants with tough problems. They do not rust and help stop food from getting dirty. These bearings also help keep things clean. They last a long time and help cut down on waste. Machines can keep working because of them. Plant managers pick these bearings because they are strong and simple to clean. More companies want these bearings as they care more about safety and working better. TFL Bearings has food-grade options made for these needs.

FAQ

What makes stainless steel bearings better for food machines?

Stainless steel bearings resist rust and corrosion. They have smooth surfaces that help workers clean them easily. These bearings do not react with food or cleaning chemicals. They help keep food safe and pure.

How do food-grade seals and lubricants work?

Food-grade seals block water, dirt, and bacteria from entering the bearing. Lubricants approved for food contact do not harm people or change food taste. These products help bearings last longer and keep machines safe.

Can stainless steel bearings handle strong cleaning chemicals?

Yes. Stainless steel bearings withstand harsh cleaners like chlorine and acids. Their special coatings and seals protect them during frequent washdowns. This helps them last longer in tough food plant environments.

Do stainless steel bearings help reduce machine downtime?

They do. Stainless steel bearings last longer and need less maintenance. They resist rust and block dirt. This means machines run longer without stopping for repairs.

Are stainless steel bearings required for food safety compliance?

Many food safety rules recommend or require stainless steel bearings. These bearings meet FDA, NSF, and EU standards. They help food plants pass inspections and keep food safe for customers.