Spherical roller bearings are made to fix misalignment in mining machines. They have a special shape with a round outer ring and barrel-shaped rollers. This shape helps the bearing handle bent shafts and angles up to 2°. These problems often happen with heavy loads and shaking. The self-aligning part lets the inside ring move to the right spot. This keeps the bearing working smoothly. Other bearings need extra changes to fix alignment. Spherical roller bearings do not need this. They can hold more weight and work better in tough mining places.

Key Takeaways

- Spherical roller bearings fix misalignment by letting the inner ring tilt inside the round outer ring. This helps machines keep working well even if shafts bend.

- Their barrel-shaped rollers can hold heavy loads and help stop wear. This makes them great for mining where there is shaking and heavy weight.

- These bearings can handle up to 2 or 3 degrees of misalignment. This helps stop early failures and expensive repairs in mining equipment.

- Putting them in the right way and doing regular care, like cleaning and adding oil, makes bearings last longer and stops surprise machine breaks.

- Using spherical roller bearings cuts repair costs and helps mining machines work longer. This saves time and money for mining companies.

Misalignment Issues in Mining

Causes of Misalignment

Mining uses big machines that work in hard places. Many things can make these machines become misaligned:

- Guide and bunton failures happen from wear, rust, or damage. These problems make mining shafts go out of line.

- Bad alignment makes hoist ropes rub more and get stressed. This can wear them out or even break them.

- The ground can move and rocks can shift. This moves shaft supports and makes misalignment worse, especially with heavy loads.

- Weather changes and shaking can make shafts grow or move. This makes it harder to keep things lined up right.

- Parts like bearings and couplings can wear out or break. Even after fixing them, misalignment can come back.

- Short repair times and old tools make it tough for workers to line things up well.

- If workers do not follow the same steps or lack training, they can make mistakes during checks.

Note: Tools like vibration analysis and thermal imaging help find misalignment early. They stop more damage from happening.

Effects on Equipment

Misalignment hurts how well mining machines work. It also makes them less reliable. Some effects are:

- More shaking and noise can hurt buildings and floors nearby.

- Too much heat and rubbing can ruin oil and make machines less efficient.

- Bearings can fail early because of extra stress and uneven forces.

- Parts like couplings and seals wear out faster and can change shape.

- Machines use more energy because they have to work harder.

- Pumps and hydraulic systems do not work as well, especially with thick slurries or high pressure.

- Machines can break down without warning, leading to expensive repairs and lost time.

Mining companies spend a lot of money fixing misalignment problems. Each problem can cost a lot and stop work. Finding misalignment early and fixing it helps save money and keeps machines working longer.

Spherical Roller Bearing Design

Self-Aligning Feature

Spherical roller bearings can fix misalignment in mining machines. The outer ring is round, so the inner ring can tilt inside it. This lets the bearing move when the shaft bends or shifts. The two rows of rollers help the bearing hold up weight from the side and from the end at the same time.

The self-aligning part helps the bearing keep working, even if the shaft and housing are not lined up. This lowers stress and wear, so mining machines last longer.

Spherical roller bearings can deal with up to 2 degrees of misalignment. This is good for mining, where heavy loads and shaking often move shafts out of place. The bearing keeps working in these hard conditions, holding a lot of weight and lowering the chance of breaking early.

Barrel-Shaped Rollers

Barrel-shaped rollers are an important part of the bearing. Each roller has a big end and a small end, so it stays in touch with the raceway. This shape lets the bearing change when the angle between the shaft and housing changes. The rollers move smoothly along the round outer ring and spread the load.

- Barrel-shaped rollers help the bearing hold heavy loads and take in shocks.

- The design stops the rollers from slipping or getting stuck, even if the shaft bends.

- Spherical roller bearings use these rollers to keep mining machines working in tough places.

The barrel-shaped rollers also let the bearing hold a lot of weight. This means the bearing can take strong side and end loads without breaking. Mining machines like crushers, conveyors, and vibrating screens need this design to keep working, even with lots of shaking and hits.

Managing Misalignment with Spherical Roller Bearings

Compensation Mechanism

Spherical roller bearings are made for tough mining jobs. The outer ring is curved, so the inner ring can tilt. This lets the bearing adjust if the shaft bends or moves. Barrel-shaped rollers fit well in the curved ring. They roll smoothly, even if things are not lined up.

Heavy loads or strong shaking can make shafts bend or shift. Spherical roller bearings let the inner ring move to match the shaft. This self-aligning part keeps the bearing working, even if the shaft is not straight. The rollers always touch the raceway, so the bearing can hold heavy loads without breaking.

Note: The curved raceway and barrel-shaped rollers work together. They help the bearing fight misalignment. This makes the bearing last longer and lowers the chance of sudden breaks.

Spherical roller bearings are great at fixing misalignment in mining machines. They help machines keep running, even when things are rough and hard to line up.

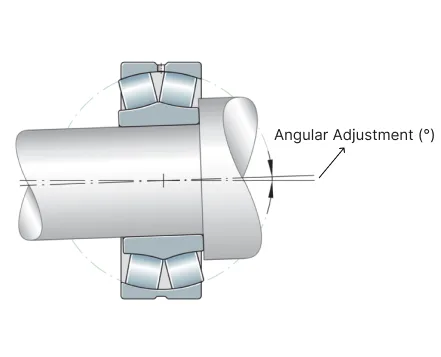

Limits of Misalignment

Every bearing can only handle so much misalignment. Spherical roller bearings are special because they can fix up to 2°–3° of misalignment. Some types used in mining can even go up to 2.5°. This high limit makes them a good pick for mining machines that move a lot and carry heavy loads.

The table below shows how much misalignment different bearings can take:

| Bearing Series Examples | Permissible Angular Adjustment (°) |

|---|---|

| 213..-E1, 222..-E1, 230 series | ~1.5 |

| 223..-E1, 231 series and others | ~2.0 |

| Sealed spherical roller bearings | ~0.5 |

The curved outer ring lets the bearing adjust for slow or fast changes. The round shape matches the rollers, so the bearing keeps working if the shaft moves or the housing changes shape.

Fixing misalignment is important for mining machines. Spherical roller bearings have a strong limit for misalignment. This helps stop early bearing breaks and means fewer repairs. Picking the right bearing and checking it often helps mining companies keep machines running and save money.

Tip: Always look at the maker’s rules for each bearing’s misalignment limit. Using the right bearing keeps machines safe and working well.

Bearing Benefits in Mining

Reduced Downtime

Mining needs machines that do not stop for long. Spherical roller bearings help keep machines running in many ways. The self-aligning design lets the bearing move if the shaft bends or is not set right. This stops bearing failures that can make mining machines stop. These bearings can hold weight from the side and end at the same time. Many other bearings cannot do this, so they break faster when loads are heavy. The special design makes less rubbing and wear. This means machines can work longer before repairs. Spherical roller bearings can handle dust, water, and tough places better than regular bearings. This makes them more dependable in mining. Good oil and regular checks help the bearing work well and stop sudden stops. Newer types, like split spherical roller bearings, are easier to fix. Workers do not have to take off drive parts or line up shafts again when changing them. This saves time and keeps workers safer.

SKF has shown these bearings make mining safer and better. They help lower the number of problems during repairs and keep machines working longer.

Longer Service Life

Spherical roller bearings last much longer than regular bearings in mining. FAG’s X-life bearings can make bearings last up to 60% longer. In hard jobs like vibratory screens, a special chromium-plated bore can make bearings last up to 70% longer. These gains come from stronger materials, better coatings, and more exact shapes. Strong steels and special coatings protect the bearing from wearing out and getting too hot. The self-aligning part lowers stress from shafts not being straight and from shaking. Better seals and oil systems keep out dust and water, so the bearing lasts longer. These bearings can take heavy hits and big loads, so they are good for crushers and mills. Real cases show these bearings can last three to ten times longer than old types. This saves money and means fewer repairs.

Bearings with high load strength and strong seals help mining companies avoid big breakdowns and keep machines working well.

Maximizing Bearing Performance

Installation Tips

Putting in a bearing the right way helps mining machines last longer. Workers should keep bearings in a clean, dry spot. They must leave them in their boxes until they need them. Clean gloves are needed when touching bearings. Before putting in the bearing, workers must clean the shaft and housing. All dirt and rust should be gone. They should use special tools to check the size of the shaft and housing. This makes sure the bearing fits well.

For small bearings, workers use tools to press them onto the shaft. They should only push on the inner ring. They must not hit the rolling parts. For big bearings, heating them with a special heater helps. The heat should not go over 120°C or the bearing can get hurt. For very big bearings, oil and hydraulic tools help slide the bearing in place without damage.

Tip: Do not drop or handle bearings roughly. Even a small drop can cause damage you cannot see. This can make the bearing fail early.

Some mistakes are using the wrong fit, getting the bearing too hot, or not tightening locknuts enough. These mistakes can make the bearing slip, get too hot, or break early. Workers should always do what the maker says when putting in bearings.

Maintenance Practices

Taking care of bearings often helps them work well in mining. Workers should look at bearings a lot for wear, noise, or shaking. They should check if the shaft and housing are lined up right. Using the right oil and following a schedule stops heat and wear.

A table below shows important steps for taking care of bearings:

| Maintenance Step | Action |

|---|---|

| Inspection | Look for noise, shaking, and wear |

| Lubrication | Use the right oil and amount; keep it clean |

| Alignment | Make sure shaft and housing are straight |

| Cleaning | Take away dust and dirt from the area |

| Monitoring | Watch for changes in temperature |

Checking bearings often helps find problems early. This stops sudden breaks and saves money on repairs. Sealed bearings need less care because they keep out dust and water.

Picking the right bearing for each job and checking it often helps mining companies stop costly stops. Putting in bearings the right way and caring for them helps them last longer, even in hard places.

Spherical roller bearings help fix misalignment in mining machines. The inner ring can move inside the outer ring. This helps the bearing work when shafts bend or move. The design lets the bearing hold heavy loads. Machines keep running, even if things are not lined up right. Mining companies do not have to stop work as much. They also spend less money because these bearings last longer and need less fixing.

- SRBs work great in places with lots of dust.

- They are used in crushers, conveyors, and big trucks.

- Strong materials help them last longer and not wear out fast.

If you need help or a special answer, TFL Bearings can help you. Contact us to keep your mining machines working well and strong.

FAQ

What makes spherical roller bearings good for mining equipment?

Spherical roller bearings can take heavy loads and fix misalignment. Their shape lets them work in places with dust, water, and rough ground. Mining machines use them a lot because they last longer and do not need fixing as often.

How much misalignment can a spherical roller bearing handle?

Most spherical roller bearings can fix 2° to 3° of shaft misalignment. Some special ones can go up to 2.5°. Always look at the maker’s guide to know the real limit.

Do spherical roller bearings need special maintenance?

Checking bearings often helps them last longer. Workers should listen for noise and feel for heat or wear. Using the right oil and keeping things clean helps stop early problems.

Where do mining companies use spherical roller bearings?

Mining companies put these bearings in crushers, conveyors, vibrating screens, and big trucks. The bearings help machines work well, even when loads are heavy or shafts bend.

Can spherical roller bearings reduce downtime in mining?

Yes. Spherical roller bearings help stop sudden breakdowns. Their self-aligning part keeps machines working, even if shafts move or bend. This helps mining companies save time and money.