Introduction

When you consider bearings, most likely you image metal ones. Long-standing metal roller bearings find usage in all kinds of machines—cars, tools, manufacturing equipment, you name it.

Most people’s impressions are that, while carrying huge loads, metal is always more dependable than plastic. Still, is this exactly the case? Are plastic bearings able to genuinely replace metal bearings? That will rely on your intended use for them. Let’s dissect it to see how metal stands against plastic.

The Differences Between Plastic and Metal Roller Bearings

What Are Plastic Roller Bearings?

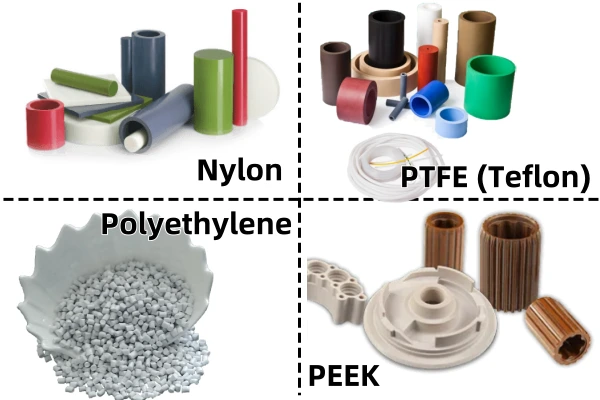

Plastic roller bearings are exactly what they sound like—bearings made from plastic materials instead of metal. These aren’t just any plastics. They are made from materials like nylon, PTFE (Teflon), polyethylene, and PEEK. These materials are lightweight, corrosion-resistant, and require less maintenance than metal bearings. Because of these benefits, plastic bearings are widely used in industries where machines need to run quietly and smoothly.

What Are Metal Roller Bearings?

Conversely, metal roller bearings are constructed of ceramic, stainless steel, or steel itself. They can manage weight, are robust, long-lasting. You will therefore find them in massive industrial machinery, autos, and aircraft.

Why Are People Switching to Plastic Roller Bearings?

Metal roller bearings have been the go-to option for years, but they’re not perfect. Here are some common issues that make people look for alternatives:

Prone to Rust and Corrosion

Rusting of metal bearings is one of their main issues. Should you have ever come across a rusty piece of metal, you understand the extent of corrosion. Like underwater equipment or food processing machinery, metal bearings are not very robust in moist or humid surroundings. Once rust builds in, the bearing’s performance falls and it may even fail completely. This is a main reason sectors including food production and marine engineering have switched to non-corrosing plastic bearings.

Heavy Weight

Metal bearings weight far more than plastic ones. For portable or lightweight equipment, this could be a major concern even if stationary devices would not be bothered by it. In robotics or aeronautical engineering, for instance, every extra weight adds up and reduces machine efficiency. Conversely, plastic bearings are lightweight and help the equipment to weigh overall less.

Requires Frequent Maintenance

To keep metal bearings operating properly, they must be routinely maintained. To lower friction, they may call for outside lubricants; but, these lubricants can draw dust and grime, building up that compromises performance. This accumulation over time could cause additional wear and tear, hence you will have to replace the bearing earlier. But plastic bearings save time and labor as they are self-lubricating and require little maintenance.

Poor Performance in Chemical Environments

Chemicals do not help metal bearings perform. Solvents, acids, and alkalis can all cause them to corrode or degrade, therefore reducing their lifetime. In fields with a lot of corrosive compounds, like chemical processing and medicines, metal bearings just don’t work. Plastic bearings, on the other hand, don’t react with poisons and keep working even in harsh conditions.

High Cost of Production

Although at first look metal bearings seem less expensive, over time they can prove more costly. Metal bearings are made from costly materials, and the manufacturing technique is more involved. Furthermore adding to the total expense are the demands for regular maintenance and ultimate replacement. Plastic bearings are a more affordable option as, in the correct environment, they often last longer and are less expensive to manufacture.

What Makes Plastic Roller Bearings So Good?

They Lubricate Themselves

The capacity of plastic bearings to self-lubricate is one of their best characteristics. Plastic bearings feature microscopic particles that naturally lubricate rather than metal bearings, which need outside lubricants. This makes them cleaner and more fit for uses like food manufacture, where lubricants are closely controlled.

Works in Hot and Cold

Plastic bearings can resist rather high temperatures between -4°C and 260°C. PEEK and certain other high-performance polymers can withstand the highest temperature—600°F. Their thinner walls also help to increase performance by lowering wear since they dissipate heat more readily than metal.

Eco-Friendly

Plastic’s light, so it saves fuel in moving parts. No nasty coatings needed either—unlike metal, which sometimes uses harmful extras. Plus, making plastic takes way less oil than metal—only about 10-15% as much.

Tough Against Chemicals

Plastic laughs at chemicals that scratch up metal bearings. It keeps sliding smooth with no fuss, even around weird liquids or stuff that’d ruin metal.

Lightweight Design

Plastic bearings are far smaller than metal ones. For machinery where weight is a factor, including portable or aeronautical equipment, this makes them perfect. Additionally low energy consumption with lighter bearings helps you save gasoline expenses.

Way Cheaper

Plastic bearings are often cheaper to produce than metal ones. Less expensive materials like PTFE and nylon also ease production. This lets you save, on costs, up to 25% as opposed to metal bearings.

When Should You Use Plastic Bearings Over Metal Bearings?

Best Uses for Plastic Bearings

Plastic bearings are a great choice for:

- Food and Beverage Industry – Since they don’t rust and don’t need lubrication, they’re safe to use around food.

- Medical Equipment – They’re lightweight, quiet, and clean, making them ideal for hospitals and labs.

- Water and Marine Applications – They won’t corrode when exposed to water.

- Chemical Processing – Many plastics resist chemicals better than metal does.

- Eco-Friendly Machines – Plastic is lighter, hence machines running plastic bearings require less energy, so lowering fuel and electricity expenses.

Best Uses for Metal Bearings

Metal bearings are better when you need:

- Heavy Machinery – Strong and long-lasting, they can handle big loads without breaking.

- Automotive Industry – Cars and trucks need bearings that can handle speed and weight.

- Aerospace Industry – Metal bearings work well in extreme temperatures and high-stress situations.

- High-Speed Applications – When things spin really fast, metal bearings tend to perform better.

Conclusion

Can synthetic bearings therefore really threaten metal bearings? The truth is—it depends. Metal is still the best choice if you require a robust, long bearing for demanding work. Plastic bearings are really worth looking at, though, if you require something low-maintenance, rust-free, and light-weight. Although they are not a perfect substitute for metal bearings in all circumstances, in the correct environment they can be really good.

TFL Bearings has you covered if you are seeking premium metal or plastic bearings. We provide a large spectrum of choices to fit several sectors. Check out our selection today and find the perfect bearing for your needs!

Popular Related Questions

Comparatively to metal bearings, are plastic roller bearings as robust?

Not very exactly. For light to medium loads, plastic bearings are fantastic; yet, metal is still the preferable option if you need anything for heavy-duty employment.

Do plastic bearings need lubrication?

Most plastic bearings are self-lubricating, so you don’t need to add oil or grease. That makes them easier to maintain.

Can plastic bearings handle high temperatures?

Some high-performance plastics can handle heat, but standard plastic bearings may not hold up well in really hot environments.

Are plastic bearings cheaper than metal bearings?

Yes, in most cases. Plastic bearings usually cost less upfront and can also save money on maintenance since they don’t need lubrication.

Can plastic bearings be used in water?

Yes! Plastic bearings don’t rust, which makes them great for wet environments like marine applications and food processing.