Common Misuses of Spherical Roller Bearings in Heavy Machinery and How to Avoid Them

Avoid costly downtime by preventing common misuses of spherical roller bearings in heavy machinery. Get tips on installation, lubrication, and maintenance.

Avoid costly downtime by preventing common misuses of spherical roller bearings in heavy machinery. Get tips on installation, lubrication, and maintenance.

Spherical roller bearings compensate for shaft misalignment in mining equipment, ensuring reliable operation and longer service life in harsh environments.

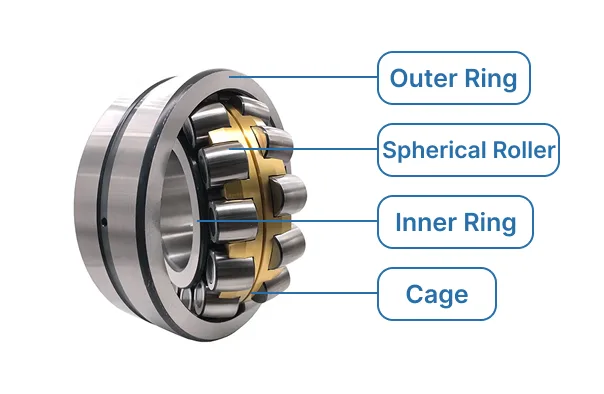

A spherical roller bearing uses barrel-shaped rollers to support heavy loads and self-align, reducing friction and handling shaft misalignment efficiently.

Roller bearings include cylindrical, needle, spherical, tapered, and thrust types, each designed for specific load and alignment needs in machinery.

A roller bearing uses rollers for line contact, offering higher load capacity and durability for heavy-duty machines in 2025 applications.

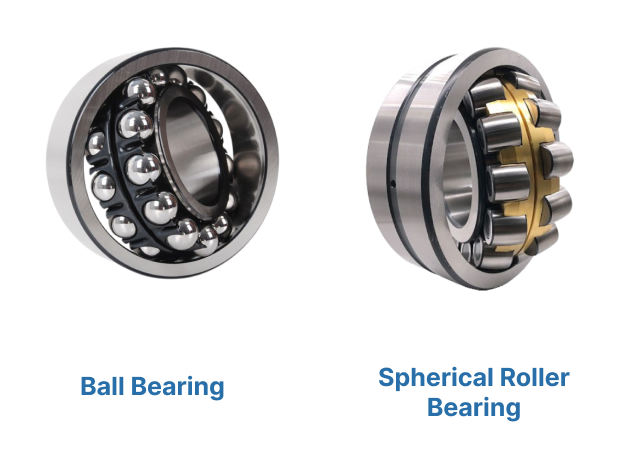

Ball bearings and spherical roller bearings have a similar appearance and can both withstand radial and axial loads. But which one is more suitable for your equipment? This article will tell you the differences between the two and how to choose the bearing that suits you.