Why Electrically Insulated Bearings Are Essential for Protecting Today’s Electric Motors

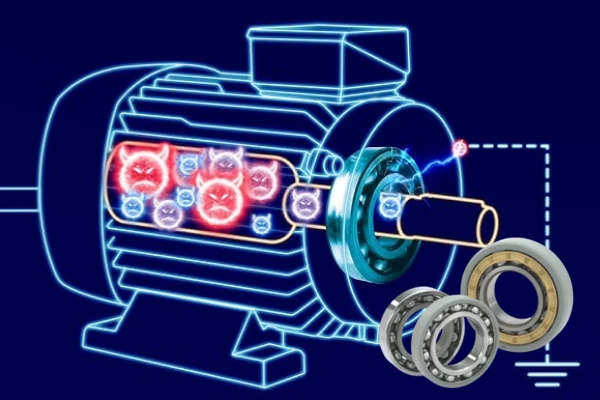

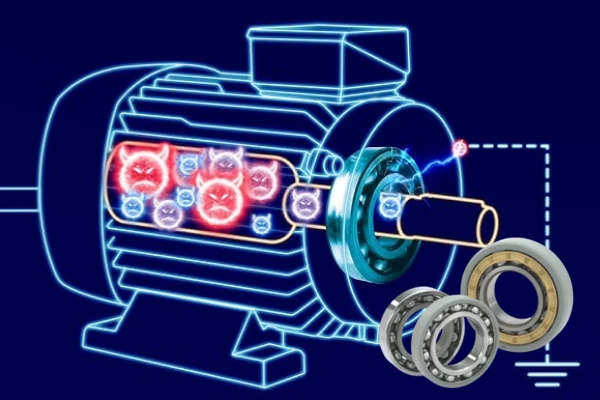

Electrically Insulated Bearings prevent bearing current corrosion in electric motors, ensuring longer service life and reducing costly downtime.

Electrically Insulated Bearings prevent bearing current corrosion in electric motors, ensuring longer service life and reducing costly downtime.

Coated insulated bearings feature a ceramic layer that blocks electrical currents, preventing bearing damage and extending machinery service life.

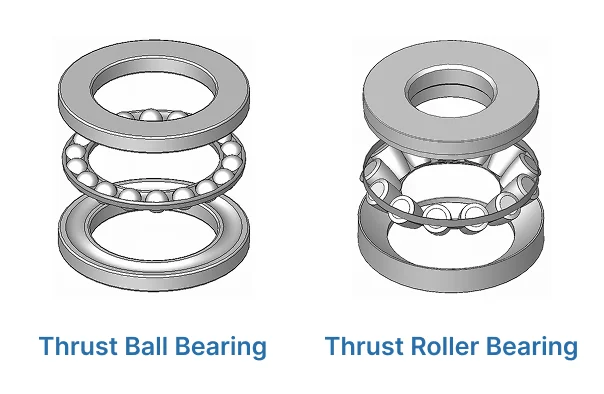

Thrust bearings and washers boost machine speed, load, and lifespan by up to 50% by reducing friction, wear, and heat for reliable, efficient operation.

Compare 8 reliable roller bearing suppliers for quality, support, and fast delivery. Find trusted options for your next industrial or engineering project.

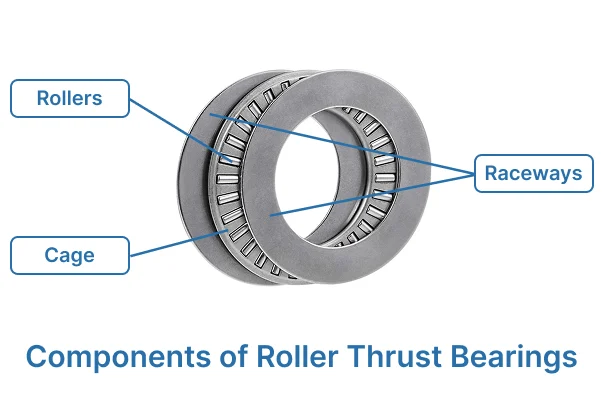

A roller thrust bearing supports heavy axial loads, reduces friction, and boosts machine life. Learn types, uses, and key tips for selection and care.

High-temperature failure in machinery bearings can halt harvests. See how a Brazilian farmer solved this issue and learn prevention strategies for your farm.

Essential roller bearing terms explained for beginners—covering parts, codes, and standards to help you choose, install, and maintain roller bearings.

Select the right heavy duty roller bearings by evaluating load, speed, environment, and material to ensure optimal performance in industrial applications.