Common Misuses of Spherical Roller Bearings in Heavy Machinery and How to Avoid Them

Avoid costly downtime by preventing common misuses of spherical roller bearings in heavy machinery. Get tips on installation, lubrication, and maintenance.

Avoid costly downtime by preventing common misuses of spherical roller bearings in heavy machinery. Get tips on installation, lubrication, and maintenance.

Spherical roller bearings compensate for shaft misalignment in mining equipment, ensuring reliable operation and longer service life in harsh environments.

Bearing OEM replacement tips: compare codes, check specs, and use cross-brand charts to ensure fit, performance, and avoid costly installation errors.

Angular Contact Bearings ensure high-speed spindle accuracy, rigidity, and long service life by optimizing preload, contact angle, and material selection.

Insulation coating materials like ceramics and composites protect bearings from electrical damage, boost efficiency, and extend service life in modern machines.

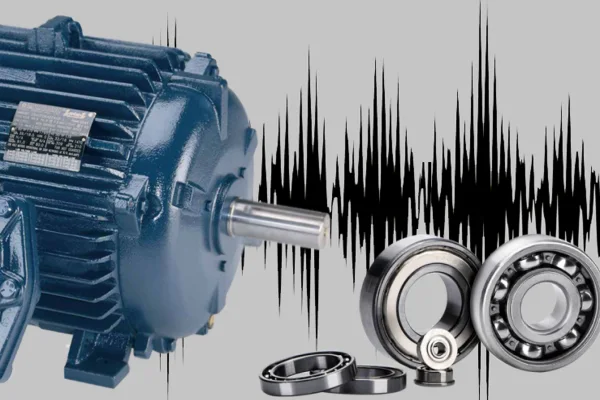

This article explores a comprehensive strategy to reduce such noise by optimizing bearing design, selecting advanced materials like ceramic rolling elements and PEEK cages, applying high-precision manufacturing techniques, and improving bearing integration in motor systems.

Learn how to interpret bearing drawing precision grades and tolerance ranges. This guide explains key tolerance symbols, GPS modifiers, and provides practical examples for reading bearing technical drawings based on ISO standards.

Insulated bearing procurement tips for electric motors: compare insulation, load, and environment to select the best bearings for your equipment.