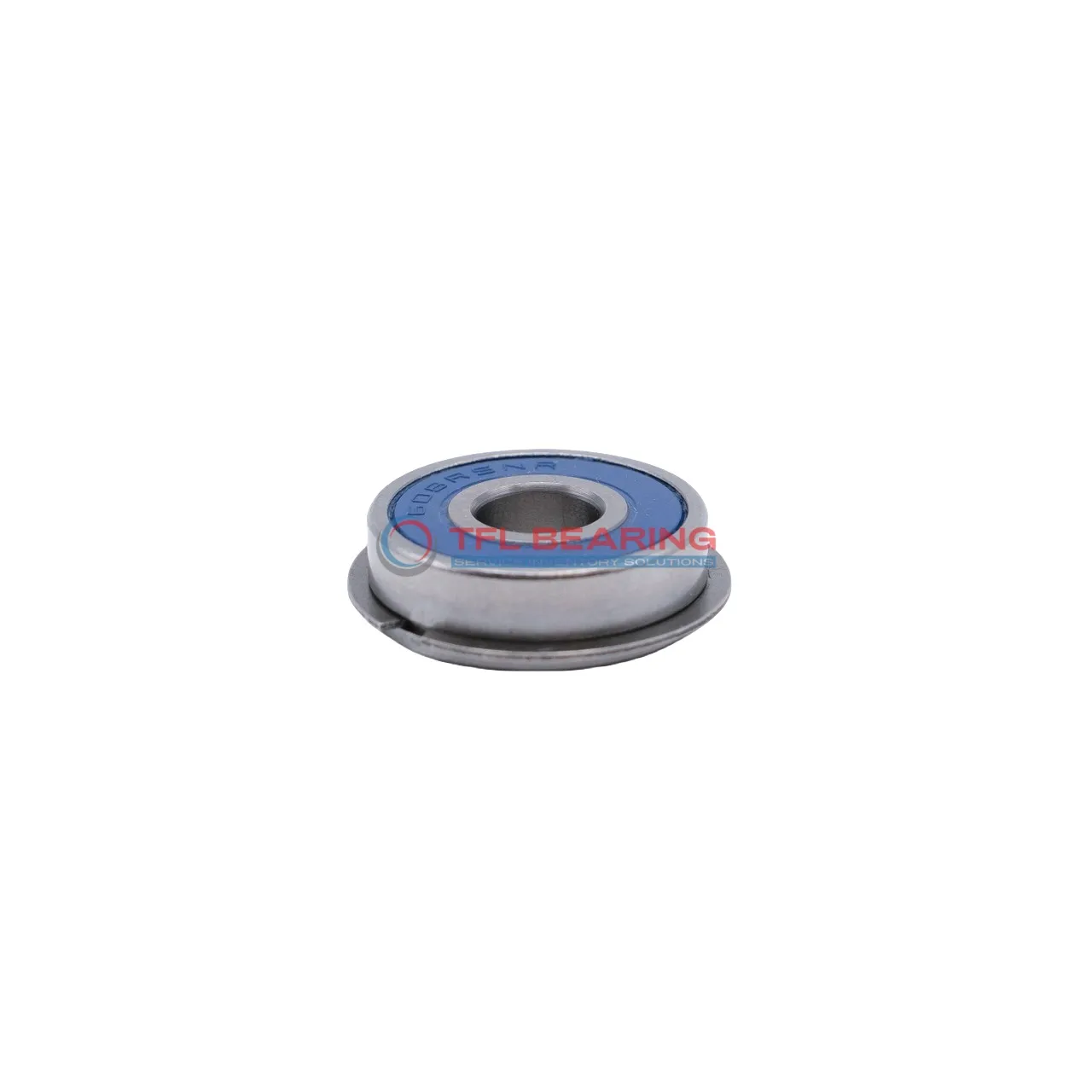

The 6308-2RS1NR is a sealed snap ring groove ball bearing with a 40mm bore and 90mm outer diameter, crafted from durable chrome steel. It handles radial loads up to 915 lbf and operates smoothly at speeds up to 7500 RPM.

Its sealed design keeps dirt out and grease in, while the snap ring ensures secure fitting in housings. The bearing performs reliably in temperatures from -30°C to 120°C.

This model is interchangeable with SKF bearings, making it a practical choice for replacements. Ideal for applications like electric motors or pumps where radial loads and secure mounting are key.

Weighing 620g, it’s sturdy yet manageable for its size. Compliant with RoHS and REACH standards for safe use.

"*" indicates required fields

Performance Features of 6308-2RS1NR Bearing

6308-2RS1NR Bearing features a sealed design, protecting it from dust and moisture for reliable operation.

The chrome steel construction ensures durability and resistance to wear in radial load applications.

With a dynamic radial load capacity of 915 lbf, it handles demanding conditions effectively.

Its snap ring groove provides secure mounting, simplifying installation and maintenance.

How Does 6308-2RS1NR Bearing Reduce Friction?

6308-2RS1NR Bearing’s sealed design minimises friction by keeping contaminants out.

The chrome steel balls and rings work smoothly together, ensuring efficient performance.

It operates quietly even at high speeds, up to 7,500 rpm, thanks to its precision engineering.

The single-row construction reduces internal friction, enhancing overall efficiency.

Built for Reliability: 6308-2RS1NR Bearing

6308-2RS1NR Bearing is crafted with chrome steel for long-lasting performance in tough conditions.

Its sealed design prevents lubricant leakage and contamination, ensuring consistent operation.

The bearing handles static radial loads up to 5395 lbf, making it suitable for heavy-duty use.

With a temperature range of -30° to 120°C, it performs reliably in various environments.

Steel vs Ceramic Bearings: Strengths of 6308-2RS1NR Bearing

6308-2RS1NR Bearing uses chrome steel for its rings and balls, offering a balance of strength and affordability.

This material choice provides excellent resistance to wear and fatigue in radial load applications.

The sealed design enhances its durability by protecting internal components from contaminants.

It maintains stable performance across a wide temperature range, from -30° to 120°C.

Industrial Uses of 6308-2RS1NR Bearing

The 6308-2RS1NR Bearing is commonly used in industrial machinery like pumps and compressors, where its sealed design protects against dust and debris. Its snap ring feature ensures secure mounting, making it ideal for high-vibration environments.

Where Is 6308-2RS1NR Bearing Used?

In automotive applications, 6308-2RS1NR Bearing fits well in wheel hubs and transmission systems, offering reliable radial load support. The chrome steel construction provides long-lasting performance even under heavy use.

Built for Heavy-Duty Use: 6308-2RS1NR Bearing

For automation equipment, 6308-2RS1NR Bearing works smoothly in robotic arms and conveyor belts, thanks to its low-maintenance sealed design. The ABEC 1 tolerance ensures consistent operation in precision tasks.

Medical vs Industrial: Where 6308-2RS1NR Bearing Excels

In medical devices like centrifuges, 6308-2RS1NR Bearing delivers quiet and stable performance. Its ISO P0 rating makes it suitable for both medical and general industrial applications.

Practical Applications of 6308-2RS1NR Bearing

For household appliances like washing machines, 6308-2RS1NR Bearing reduces noise and vibration. The sealed construction keeps out moisture, extending the bearing’s lifespan in damp conditions.

"*" indicates required fields