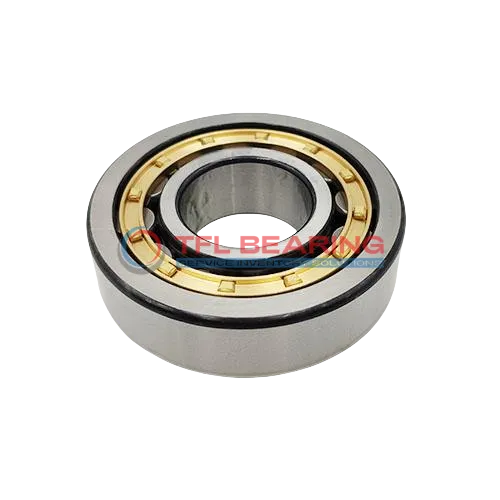

The NU 30/600 ECMA/HA1 is a single row cylindrical roller bearing with a large 600mm bore and 870mm outer diameter, built from tough chrome steel. It handles heavy radial loads up to 1,212,750 lbf and combined loads with ease, suitable for speeds up to 1000 RPM.

Its brass cage and open design allow smooth operation and easy lubrication with grease or oil. The bearing works reliably in temperatures from -30°C to 110°C, making it versatile for various conditions.

This model is interchangeable with SKF bearings, offering a practical replacement option. Ideal for heavy machinery, industrial gearboxes, or large equipment where robust performance is needed.

Weighing 420kg, it’s a substantial unit designed for durability. Compliant with RoHS and REACH standards, ensuring safe and eco-friendly use.

"*" indicates required fields

Performance Features of NU 30/600 ECMA/HA1 Bearing

NU 30/600 ECMA/HA1 Bearing is built with chrome steel rings and rollers, offering excellent resistance to combined loads.

Its dynamic radial load capacity reaches 1,212,750 lbf, ensuring reliable performance in heavy-duty applications.

The brass cage, centred on the outer ring, maintains roller alignment for smooth operation.

With a maximum speed of 1,000 rpm, it balances durability and efficiency in demanding conditions.

How Does NU 30/600 ECMA/HA1 Bearing Resist Wear?

NU 30/600 ECMA/HA1 Bearing’s chrome steel construction minimises wear, even under high radial loads.

The brass cage reduces friction between rollers, extending the bearing’s service life.

Its precise tolerances ensure consistent performance, reducing the need for frequent maintenance.

The open design allows for easy lubrication, further enhancing durability.

Built for Reliability: NU 30/600 ECMA/HA1 Bearing

NU 30/600 ECMA/HA1 Bearing handles extreme radial loads up to 2,475,000 lbf static, making it ideal for heavy machinery.

The single-row cylindrical design ensures stability and precision in combined load applications.

Its temperature range of -30° to 110°C allows operation in various environments.

The grease or oil lubrication options provide flexibility for different maintenance needs.

Steel vs Ceramic Bearings: Strengths of NU 30/600 ECMA/HA1 Bearing

NU 30/600 ECMA/HA1 Bearing’s chrome steel construction offers superior strength for industrial applications.

The material choice ensures durability under high loads, outperforming ceramic in heavy-duty scenarios.

Its brass cage provides excellent heat dissipation, reducing thermal stress.

The bearing’s large size (600 mm bore) makes it suitable for heavy equipment where reliability is crucial.

Industrial Uses of NU 30/600 ECMA/HA1 Bearing

NU 30/600 ECMA/HA1 Bearing is commonly used in heavy industrial machinery, such as large gearboxes and rolling mills, where its high radial load capacity is essential. The brass cage design helps reduce friction, making it suitable for continuous operation.

What Makes NU 30/600 ECMA/HA1 Bearing a Preferred Choice?

In wind turbine applications, NU 30/600 ECMA/HA1 Bearing handles combined loads efficiently, thanks to its robust chrome steel construction. Its wide temperature range ensures reliability even in harsh environmental conditions.

Perfect Fit for Automation: NU 30/600 ECMA/HA1 Bearing

NU 30/600 ECMA/HA1 Bearing is ideal for automated production lines, where precision and durability are key. The open seal design allows for easy lubrication, extending its service life in high-speed scenarios.

Automotive vs Aerospace: Applications of NU 30/600 ECMA/HA1 Bearing

In automotive manufacturing, NU 30/600 ECMA/HA1 Bearing supports large presses and stamping machines. For aerospace, its high static radial load capacity makes it useful in ground support equipment.

Where Is NU 30/600 ECMA/HA1 Bearing Used?

NU 30/600 ECMA/HA1 Bearing can be found in mining equipment, where its ability to handle heavy loads and vibrations is crucial. The grease or oil lubrication options provide flexibility for different operational needs.

"*" indicates required fields