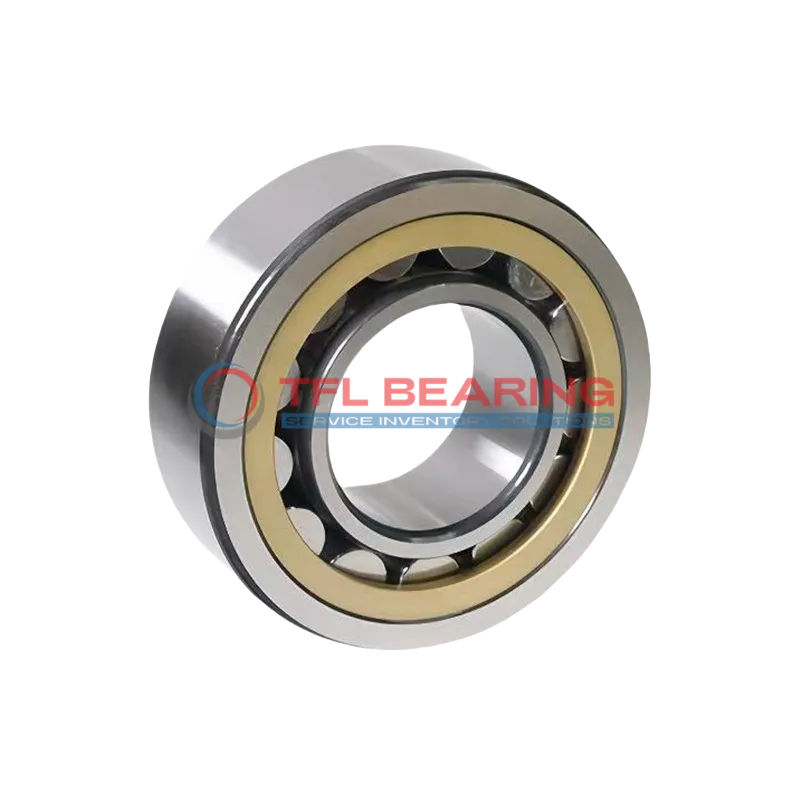

The NU 226 ECML is a single row cylindrical roller bearing with a 130mm bore and 230mm outer diameter, crafted from durable chrome steel. It handles combined loads up to 93375 lbf and runs smoothly at speeds up to 5000 RPM.

Its brass cage design ensures stability, while the open construction allows easy lubrication with grease or oil. The bearing operates well in temperatures from -30°C to 110°C.

With a width of 40mm and chamfer dimensions of 3mm, it fits snugly in tight spaces. Ideal for heavy-duty applications like industrial gearboxes or machinery where radial and axial loads are present.

Weighing 7.13kg, it’s robust yet manageable for its size. Compliant with RoHS and REACH standards, it’s a reliable choice for replacements, interchangeable with SKF bearings.

"*" indicates required fields

Performance Features of NU 226 ECML Bearing

NU 226 ECML Bearing is built with chrome steel rings and rollers, offering high resistance to combined loads.

Its dynamic radial load capacity reaches 93,375 lbf, making it suitable for heavy-duty applications.

The brass cage ensures smooth operation and reduces friction, enhancing overall performance.

With a maximum speed of 5,000 rpm, it delivers reliable efficiency in various conditions.

How Does NU 226 ECML Bearing Resist Wear?

NU 226 ECML Bearing’s chrome steel construction provides excellent wear resistance, even under high stress.

The brass cage keeps the rollers aligned, minimising contact and prolonging service life.

Its open design allows for easy lubrication, further reducing wear and maintenance needs.

This bearing operates smoothly within a temperature range of -30° to 110°C.

Engineered for Precision: NU 226 ECML Bearing

NU 226 ECML Bearing features precise dimensions, with a bore diameter of 130 mm and outer diameter of 230 mm.

The single-row cylindrical design ensures accurate load distribution and reduces operational noise.

Its brass cage and chrome steel rollers enhance durability and performance.

This bearing is ideal for applications requiring high precision and reliability.

Why Choose NU 226 ECML Bearing for Heavy Loads?

NU 226 ECML Bearing handles heavy radial loads up to 102,375 lbf static and 93,375 lbf dynamic.

The chrome steel rollers and rings provide robust support in demanding environments.

Its brass cage maintains roller alignment, ensuring smooth operation under stress.

With a width of 40 mm, it offers stability and strength for industrial applications.

Optimized for Efficiency: NU 226 ECML Bearing

NU 226 ECML Bearing’s design reduces friction, improving energy efficiency in machinery.

The open seal type allows for easy lubrication with grease or oil, enhancing performance.

Its temperature tolerance from -30° to 110°C ensures reliability in varying conditions.

This bearing is a cost-effective solution for long-term use in heavy industries.

Industrial Uses of NU 226 ECML Bearing

NU 226 ECML Bearing is commonly used in heavy machinery like industrial gearboxes and large electric motors, where its cylindrical roller design handles high radial loads efficiently. The brass cage ensures smooth operation even at high speeds.

Where Is NU 226 ECML Bearing Used?

You’ll often find NU 226 ECML Bearing in conveyor systems and mining equipment, thanks to its robust construction and ability to withstand harsh conditions. Its open design allows for easy lubrication, extending service life.

Built for Heavy-Duty Use: NU 226 ECML Bearing

NU 226 ECML Bearing excels in applications like steel mills and paper processing machines, where combined loads are common. The chrome steel rollers and rings provide durability under continuous operation.

Automotive vs Aerospace: Applications of NU 226 ECML Bearing

In automotive settings, NU 226 ECML Bearing supports drivetrain components, while in aerospace, it’s used in auxiliary systems. Its metric sizing and high-speed capability make it versatile across industries.

Perfect Fit for Automation: NU 226 ECML Bearing

NU 226 ECML Bearing is ideal for robotic arms and automated assembly lines, where precision and reliability are key. The brass cage reduces friction, ensuring consistent performance over time.

"*" indicates required fields