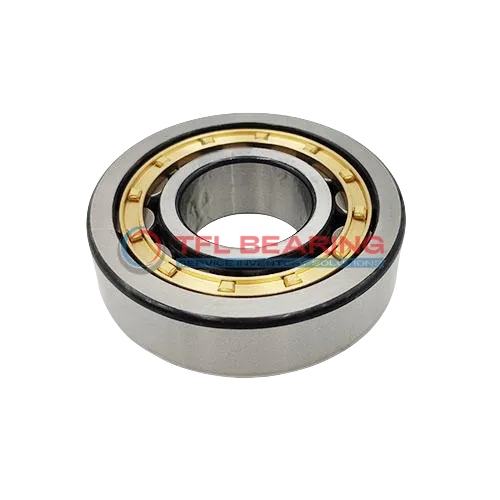

The NU 12/630 ECMA/HB1 is a single row cylindrical roller bearing with a large 630mm bore and 1150mm outer diameter, built from sturdy chrome steel. It handles combined loads up to 1930500 lbf and runs smoothly at speeds up to 1000 RPM.

Its brass cage design ensures durability, while the open construction allows easy lubrication with grease or oil. The bearing operates well in temperatures from -30°C to 110°C.

With a weight of 1109kg, this robust bearing is ideal for heavy-duty applications like industrial machinery or large gearboxes. It’s interchangeable with SKF bearings, making it a reliable replacement option.

The chamfered edges (12mm) and permissible axial displacement (13.5mm) add to its versatility. Compliant with RoHS and REACH standards, it’s a safe choice for various industrial uses.

"*" indicates required fields

Performance Features of NU 12/630 ECMA/HB1 Bearing

NU 12/630 ECMA/HB1 Bearing is built with chrome steel rings and rollers, offering high resistance to combined loads.

Its dynamic radial load capacity reaches 1,930,500 lbf, making it suitable for heavy-duty applications.

The brass cage ensures smooth operation and reduces wear, even at high speeds up to 1,000 rpm.

With a temperature range of -30° to 110°C, it performs reliably in various environments.

NU 12/630 ECMA/HB1 Bearing’s open design allows for easy lubrication with grease or oil.

Its precise dimensions and tolerances ensure a perfect fit and long service life.

Industrial Uses of NU 12/630 ECMA/HB1 Bearing

NU 12/630 ECMA/HB1 Bearing is commonly used in heavy industrial machinery, such as large gearboxes and rolling mills, where its high load capacity handles both radial and axial forces. The brass cage design ensures smooth operation even under demanding conditions.

What Makes NU 12/630 ECMA/HB1 Bearing a Preferred Choice?

In wind turbine applications, NU 12/630 ECMA/HB1 Bearing’s robust construction and grease lubrication make it reliable for long-term use. Its metric dimensions and compatibility with SKF models simplify replacements in European equipment.

Perfect Fit for Automation: NU 12/630 ECMA/HB1 Bearing

NU 12/630 ECMA/HB1 Bearing works well in automated production lines, particularly in large conveyor systems where precision and durability are key. The chrome steel rollers provide consistent performance over extended periods.

Automotive vs Aerospace: Applications of NU 12/630 ECMA/HB1 Bearing

In automotive testing rigs, NU 12/630 ECMA/HB1 Bearing supports high loads during endurance trials. For aerospace ground equipment, its temperature tolerance ensures stability in varying climates.

Where Is NU 12/630 ECMA/HB1 Bearing Used?

NU 12/630 ECMA/HB1 Bearing is ideal for mining equipment, where its large size and strength handle extreme loads. The open seal design allows for easy maintenance in dusty environments.

"*" indicates required fields