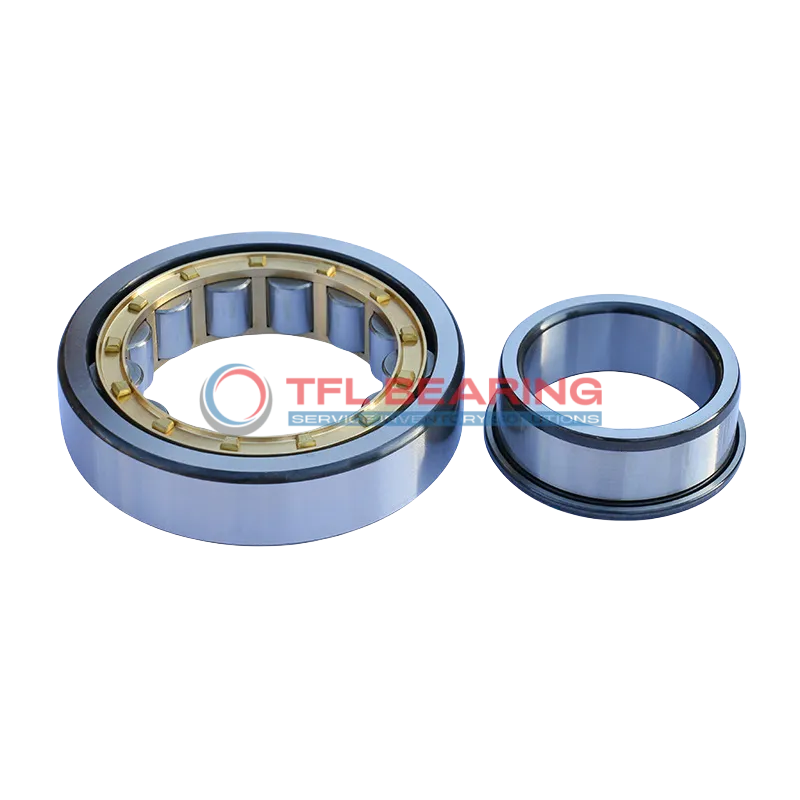

The NJ 218 ECM is a single row cylindrical roller bearing with a 90mm bore and 160mm outer diameter, crafted from durable chrome steel. It handles combined loads up to 46800 lbf and runs smoothly at speeds up to 5000 RPM.

Its brass cage keeps rollers centred for even load distribution, while the open design allows easy lubrication with grease or oil. The bearing operates well in temperatures from -30°C to 110°C.

This model is interchangeable with SKF bearings, making it a practical choice for replacements. Ideal for heavy-duty applications like gearboxes or industrial machinery where radial and axial loads are present.

Weighing 2.79kg, it’s sturdy yet manageable for its size. Compliant with RoHS and REACH standards for safe use.

"*" indicates required fields

Performance Features of NJ 218 ECM Bearing

NJ 218 ECM Bearing is built with chrome steel rings and rollers, offering strong resistance to combined loads.

Its dynamic radial load capacity reaches 46,800 lbf, ensuring reliable performance in heavy-duty applications.

The brass cage keeps the rollers centred, reducing friction and extending service life.

With a maximum speed of 5,000 rpm, it balances durability and efficiency in various conditions.

NJ 218 ECM Bearing operates smoothly in temperatures ranging from -30° to 110°C.

Its open design allows for easy lubrication with grease or oil, reducing maintenance needs.

The precise tolerances of NJ 218 ECM Bearing ensure consistent performance.

Its single-row cylindrical design is ideal for applications requiring high radial load capacity.

Industrial Uses of NJ 218 ECM Bearing

NJ 218 ECM Bearing is commonly used in heavy machinery like conveyor systems and industrial gearboxes, where its cylindrical roller design handles combined loads efficiently. The brass cage ensures smooth operation even at high speeds up to 5000 rpm.

Where Is NJ 218 ECM Bearing Used?

In automotive applications, NJ 218 ECM Bearing fits well in transmissions and differentials, thanks to its robust chrome steel construction. Its metric sizing makes it a versatile choice for various vehicle designs.

Built for Heavy-Duty Use: NJ 218 ECM Bearing

NJ 218 ECM Bearing excels in construction equipment, supporting axial and radial loads in cranes and excavators. The open seal design allows for easy lubrication, extending its service life in tough conditions.

Automotive vs Aerospace: Applications of NJ 218 ECM Bearing

While NJ 218 ECM Bearing is popular in car transmissions, it also finds use in aircraft landing gear systems. Its high dynamic load capacity makes it reliable for both ground and air applications.

Perfect Fit for Automation: NJ 218 ECM Bearing

NJ 218 ECM Bearing is ideal for robotic arms and automated assembly lines, where precision and durability are key. The grease or oil lubrication options adapt to different operational needs.

"*" indicates required fields