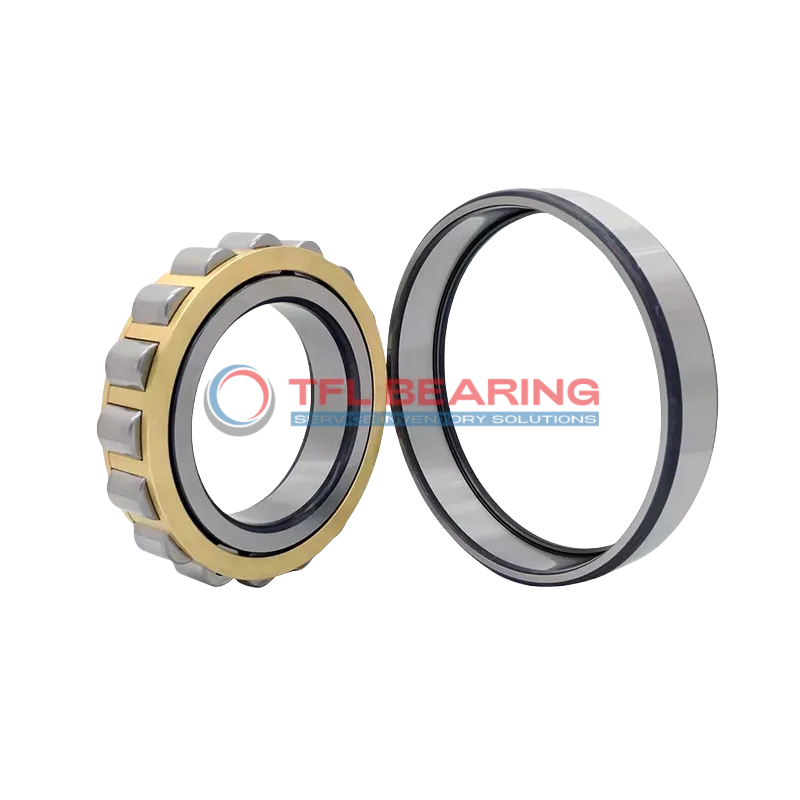

The N 318 ECM is a single row cylindrical roller bearing with a 90mm bore and 190mm outer diameter, crafted from durable chrome steel. It handles combined loads up to 82125 lbf and runs smoothly at speeds up to 4000 RPM.

Its brass cage keeps rollers centred for stable performance, while the open design allows easy lubrication with grease or oil. The bearing operates well in temperatures from -30°C to 110°C.

With a width of 43mm, it fits compact spaces while offering robust support. The inner ring design ensures precise alignment, making it suitable for heavy-duty applications.

Ideal for industrial machinery or gear systems where radial and axial loads are present. Compliant with RoHS and REACH standards, it’s a reliable choice for replacements, interchangeable with SKF bearings. Weighing 6kg, it balances strength and practicality.

"*" indicates required fields

Performance Features of N 318 ECM Bearing

N 318 ECM Bearing is built with chrome steel rings and rollers, offering strong resistance to combined loads.

Its dynamic radial load capacity reaches 82125 lbf, making it suitable for heavy-duty applications.

The brass cage ensures proper roller alignment, reducing friction and wear.

With a maximum speed of 4000 rpm, it delivers reliable performance in various conditions.

How Does N 318 ECM Bearing Reduce Friction?

N 318 ECM Bearing features a brass cage that centres the rollers, minimising friction during operation.

The chrome steel construction enhances durability while maintaining smooth performance.

Its design allows for permissible axial displacement of up to 2.5 mm, accommodating slight misalignments.

This makes it a practical choice for applications requiring both radial and axial load handling.

Engineered for Precision: N 318 ECM Bearing

N 318 ECM Bearing’s precise dimensions (90 mm x 190 mm x 43 mm) ensure accurate fit and performance.

The chrome steel rollers and rings provide excellent load distribution, reducing stress concentrations.

With a temperature range of -30° to 110 °C, it operates reliably in various environments.

Its open design allows for easy lubrication with either grease or oil, simplifying maintenance.

Steel vs Ceramic Bearings: Strengths of N 318 ECM Bearing

N 318 ECM Bearing uses chrome steel for both rings and rollers, offering a balance of strength and cost-effectiveness.

The brass cage enhances roller alignment, improving efficiency and reducing wear.

With a static radial load capacity of 81000 lbf, it handles heavy loads without compromising performance.

Its compliance with RoHS and REACH standards ensures environmental and safety considerations are met.

Industrial Uses of N 318 ECM Bearing

N 318 ECM Bearing is commonly used in heavy machinery like gearboxes and industrial pumps, where its cylindrical roller design handles both radial and axial loads efficiently. The brass cage ensures smooth operation even at high speeds.

Where Is N 318 ECM Bearing Used?

You’ll often find N 318 ECM Bearing in automotive transmissions, where its robust construction supports high torque and frequent load changes. The chrome steel rollers provide excellent durability under demanding conditions.

Built for Heavy-Duty Use: N 318 ECM Bearing

N 318 ECM Bearing excels in applications like conveyor systems, where its open design allows for easy lubrication and maintenance. The metric sizing makes it a versatile choice for various industrial setups.

Automotive vs Aerospace: Applications of N 318 ECM Bearing

In automotive settings, N 318 ECM Bearing is ideal for wheel hubs and drivetrains, while its precision also suits aerospace components like turbine shafts. The temperature range ensures reliability in diverse environments.

Perfect Fit for Automation: N 318 ECM Bearing

N 318 ECM Bearing works well in robotic arms and automated assembly lines, thanks to its high-speed capability and low friction. The combined load handling makes it adaptable for dynamic movements.

"*" indicates required fields