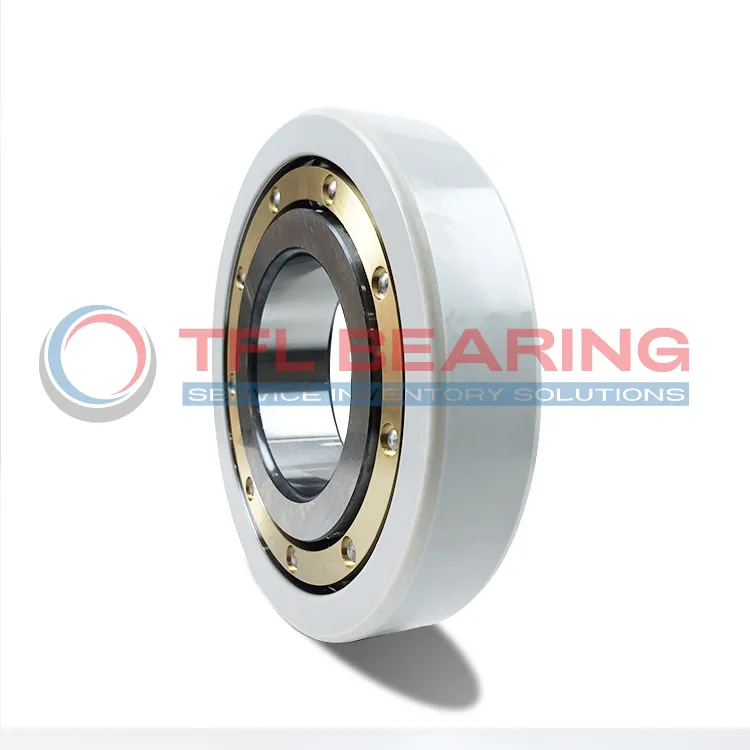

The 6326-M-C3-SQ77 is an electrically insulated ball bearing with a 130mm bore and 280mm outer diameter, designed to prevent electrical currents from damaging machinery. It handles dynamic loads up to 229kN and spins smoothly at speeds up to 5000 RPM.

Its outer ring features a special insulation coating (SQ77) with a breakdown voltage of 1000-3000V, making it ideal for electric motors or generators. The brass cage ensures durability and reduces friction.

With a C3 radial clearance, it accommodates thermal expansion in high-speed applications. The coating thickness ranges from 100 to 500µm, providing reliable insulation.

Weighing 17.64kg, it’s robust for industrial use. Compliant with RoHS standards, it’s a safe choice for environments where electrical resistance (50-200 MΩ) is crucial. Suitable for wind turbines or railway systems.

"*" indicates required fields

How Is 6326-M-C3-SQ77 Bearing Engineered for Reliability?

6326-M-C3-SQ77 Bearing features an insulating coating on the outer ring, preventing electrical damage and ensuring smooth operation.

Its brass cage enhances durability and maintains ball alignment under high-speed conditions.

With a basic dynamic load rating of 229.0 kN, it handles heavy loads efficiently.

The breakdown voltage of 1000~3000 V makes it suitable for electrically demanding environments.

What Makes 6326-M-C3-SQ77 Bearing Suitable for High-Temperature Applications?

6326-M-C3-SQ77 Bearing’s insulation coating withstands high temperatures, maintaining performance in challenging conditions.

The brass cage ensures stability, even at the reference speed of 5000.0 r/min.

Its electrical resistance of 50~200 MΩ reduces the risk of current-related failures.

The C3 radial internal clearance allows for thermal expansion, enhancing longevity.

Built for Reliability: 6326-M-C3-SQ77 Bearing

6326-M-C3-SQ77 Bearing is designed with a robust brass cage, ensuring consistent performance under stress.

The insulation coating protects against electrical currents, extending its service life.

With a static load rating of 216.0 kN, it offers reliable support in heavy-duty applications.

Its layer thickness of 100~500 µm provides added protection against wear and electrical damage.

Steel vs Ceramic Bearings: Strengths of 6326-M-C3-SQ77 Bearing

6326-M-C3-SQ77 Bearing’s chrome steel construction offers superior strength and resistance to heavy loads.

The insulating coating provides an edge over standard bearings in electrically active environments.

Its brass cage ensures smooth operation, even at high speeds.

With a net weight of 17.64 kg, it balances durability and practicality for industrial use.

Industrial Uses of 6326-M-C3-SQ77 Bearing

This bearing is commonly used in electric motors and generators, where its insulation coating prevents electrical arcing and extends component life. The brass cage adds durability, making it suitable for high-speed industrial applications.

Where Is 6326-M-C3-SQ77 Bearing Used?

You’ll find this bearing in wind turbines and railway systems, where its high breakdown voltage ensures reliable performance under electrical stress. The C3 clearance allows for thermal expansion in demanding environments.

Built for Heavy-Duty Use: 6326-M-C3-SQ77 Bearing

With a dynamic load rating of 229 kN, this bearing handles heavy loads in mining equipment and large pumps. The insulation coating also makes it a safe choice for environments with stray currents.

Automotive vs Aerospace: Applications of 6326-M-C3-SQ77 Bearing

In automotive alternators, this bearing resists electrical damage, while in aerospace, its high-speed capability suits auxiliary power units. The SQ77 coating ensures consistent performance in both fields.

Perfect Fit for Automation: 6326-M-C3-SQ77 Bearing

This bearing works well in robotic arms and CNC machinery, where electrical insulation prevents downtime. Its 5000 r/min reference speed keeps operations smooth and efficient.

"*" indicates required fields