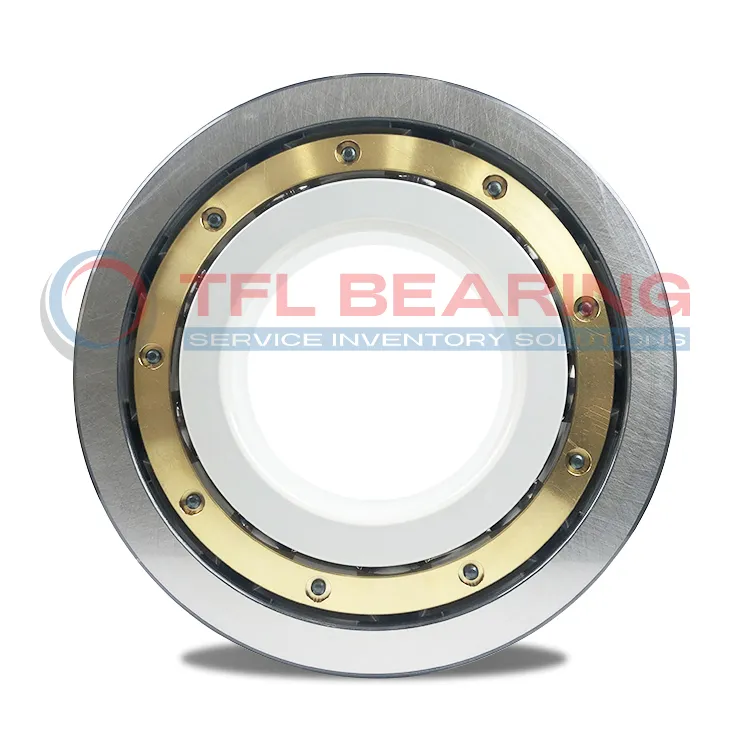

The 6322-M-C3-SQ77E is an electrically insulated ball bearing with a 110mm bore and 240mm outer diameter, designed to handle both radial and axial loads. Its ceramic-coated inner ring provides excellent insulation, preventing electrical currents from damaging the bearing.

This model can handle dynamic loads up to 216kN and static loads up to 186kN, making it suitable for heavy-duty applications. It operates smoothly at speeds up to 5600 RPM and works in temperatures from -30°C to 110°C.

The brass cage ensures durability, while the C3 radial clearance allows for thermal expansion. With a breakdown voltage of 1000-3000V, it’s ideal for electric motors or generators where electrical insulation is crucial.

Weighing 11.21kg, it’s robust yet manageable for industrial use. Compliant with RoHS standards, it’s a reliable choice for demanding environments.

"*" indicates required fields

How Is 6322-M-C3-SQ77E Bearing Engineered for Reliability?

6322-M-C3-SQ77E Bearing features a ceramic-coated inner ring, providing excellent electrical insulation.

The brass cage ensures smooth operation and reduces friction, even at high speeds.

With a breakdown voltage of 1000-3000 V, it prevents electrical damage in demanding environments.

Its dynamic load rating of 216 kN makes it suitable for heavy-duty applications.

The C3 radial internal clearance allows for thermal expansion, ensuring consistent performance.

This design combines durability and electrical resistance for reliable operation.

Industrial Uses of 6322-M-C3-SQ77E Bearing

The 6322-M-C3-SQ77E Bearing is commonly used in industrial motors and generators, where electrical insulation is crucial to prevent current leakage. Its ceramic-coated inner ring ensures reliable performance in high-voltage environments.

In wind turbines, 6322-M-C3-SQ77E Bearing helps manage electrical currents induced by variable speeds, reducing wear and extending service life. The brass cage adds durability, making it suitable for harsh outdoor conditions.

Where Is 6322-M-C3-SQ77E Bearing Used?

You’ll often find 6322-M-C3-SQ77E Bearing in electric vehicle drivetrains, where its insulation properties protect against stray currents. The C3 clearance allows for thermal expansion during high-speed operation.

It’s also a great fit for railway traction systems, handling both axial and radial loads while maintaining electrical safety. The coating’s breakdown voltage range ensures compatibility with various power systems.

Built for Heavy-Duty Use: 6322-M-C3-SQ77E Bearing

6322-M-C3-SQ77E Bearing excels in mining equipment, where dust and moisture resistance are essential. The ceramic layer prevents arcing, even in damp conditions.

For conveyor systems in factories, this bearing reduces downtime by withstanding both mechanical stress and electrical interference. Its static load rating of 186 kN makes it robust for continuous operation.

Automotive vs Aerospace: Applications of 6322-M-C3-SQ77E Bearing

In automotive hybrids, 6322-M-C3-SQ77E Bearing isolates high-voltage components like inverters, ensuring safe operation. The 50 MΩ resistance prevents short circuits.

Aerospace applications benefit from its lightweight design and ability to handle rapid speed changes. The 5600 r/min reference speed suits auxiliary power units well.

Practical Applications of 6322-M-C3-SQ77E Bearing

Medical imaging devices use 6322-M-C3-SQ77E Bearing to avoid electrical noise in sensitive diagnostics. The precise clearance minimizes vibration for clearer scans.

In robotics, it ensures smooth joint movement without interference from servo motor currents. The 240 mm OD fits compactly into articulated arms.

"*" indicates required fields