Home / Product / Roller Bearings / Tapered Roller Bearings / Single Tapered Roller Bearings / TS (Tapered Single Roller Bearings) (Metric)

TS (Tapered Single Roller Bearings) (Metric)

TS (Tapered Single Roller Bearings) (Metric) are the industry standard for modern machinery and equipment. These tapered roller bearings are engineered with a specific focus on metric tapered roller bearings sizes, ensuring they integrate seamlessly into global industrial applications. Their robust design allows them to manage a combination of high radial loads and axial thrust, making them a crucial component in everything from heavy-duty vehicles to complex industrial gearboxes.

Loading...

Total 457 Results

Part Number

Sizes

Cone Part Number

Cup Part Number

Bore Dia

Outer Dia

Cone Width

Cup Width

Width

Series

Weight

32960

300 mm x 420 mm x 76 mm

X32960M

Y32960M

300 mm

420 mm

76 mm

57 mm

76 mm

32960

68.85 lb

32064X

320 mm x 480 mm x 100 mm

X32064XM

Y32064XM

320 mm

480 mm

100 mm

74 mm

100 mm

32064XM

131.40 lb

32968

340 mm x 460 mm x 76 mm

X32968M

Y32968M

340 mm

460 mm

76 mm

57 mm

76 mm

32968M

76.06 lb

32972

360 mm x 480 mm x 76 mm

X32972M

Y32972M

360 mm

480 mm

76 mm

57 mm

76 mm

32972M

79.81 lb

JL580946-JL580914

630 mm x 850 mm x 108 mm

JL580946

JL580914

630 mm

850 mm

100 mm

78 mm

108 mm

L580900

348.33 lb

JL286948-JL286910

928 mm x 1060 mm x 92 mm

JL286948

JL286910

928 mm

1060 mm

90 mm

76 mm

92 mm

L286900

267.20 lb

JL286948H-JL286910

928 mm x 1060 mm x 92 mm

JL286948H

JL286910

928 mm

1060 mm

90 mm

76 mm

92 mm

L286900

265.00 lb

JL286949-JL286910

930 mm x 1060 mm x 92 mm

JL286949

JL286910

930 mm

1060 mm

90 mm

76 mm

92 mm

L286900

262.79 lb

JL286949H-JL286910

930 mm x 1060 mm x 92 mm

JL286949H

JL286910

930 mm

1060 mm

90 mm

76 mm

92 mm

L286900

260.59 lb

TS Metric Tapered Roller Bearing Design and Benefits

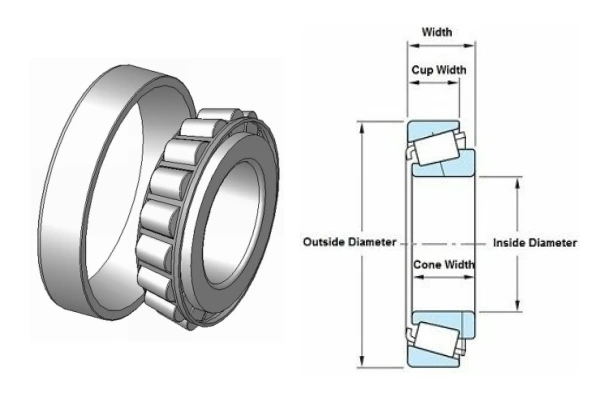

TS (Tapered Single Roller Bearings) are designed with a unique geometry that allows their tapered rollers to run on tapered raceways. This design enables them to efficiently accommodate both radial loads and axial loads in one direction. The larger end of the tapered rollers, guided by a flange on the inner ring, ensures precise alignment and optimal load distribution.

These metric tapered roller bearings are particularly beneficial due to their ability to be set up with an optimal internal clearance during mounting. This adjustability allows for fine-tuning the bearing’s performance to specific application requirements, enhancing both rigidity and operational lifespan. From automotive transmissions to industrial gearboxes, the reliable performance of single row tapered roller bearings is key.

Applications and Versatility of TFL TS Metric Tapered Bearings

The robust construction and high load-carrying capacity of TS (Tapered Single Roller Bearings) (Metric) make them exceptionally versatile across a wide array of industries. These bearings are frequently employed in wheels of automobiles and trucks, agricultural machinery, construction equipment, and industrial machinery where varying speeds and heavy loads are common.

TFL’s metric tapered roller bearings are engineered for performance and longevity in the most demanding environments. Whether it’s the precise rotational requirements of a machine tool spindle or the robust support needed in a heavy-duty gearbox, our TS Metric series delivers. The precision manufacturing of these bearings helps reduce friction, heat generation, and wear, contributing to improved energy efficiency and extended operational life for machinery. When considering roller bearing sizes for specific applications, TFL provides comprehensive data to ensure the right fit for your needs.

Lubrication and Maintenance for Longevity

Proper tapered roller bearing lubrication is critical for ensuring long service life and reliable performance. The type and amount of lubricant can significantly impact the bearing’s efficiency and lifespan. Lubricants reduce friction, dissipate heat, and protect the surfaces from wear and corrosion. Both grease and oil can be used, depending on the application and operating conditions.

Regular maintenance and tapered roller bearing installation practices are also key. Correct installation ensures the bearing is properly seated and has the correct clearance. This prevents premature wear and overheating. For demanding applications, a sealed tapered roller bearing can provide an added layer of protection against contaminants, reducing the need for frequent maintenance.

FREQUENTLY ASKED QUESTIONS

What are the primary advantages of metric tapered roller bearings?

The primary advantage is their universal adoption in modern engineering. Most new machinery and equipment are designed with metric dimensions, making these bearings the standard choice. Using metric tapered roller bearings simplifies design, sourcing, and maintenance globally, as they align with international standards. Their precise sizing allows for seamless integration into various systems, ensuring consistent and reliable performance.

What is the difference between a single row tapered roller bearing and a double row tapered roller bearing?

A single row bearing supports a combination of radial load and axial load in one direction. A double row tapered roller bearing, in contrast, can support radial load and axial load from both directions simultaneously. This makes double row bearings ideal for applications requiring higher rigidity and greater load capacity, such as large industrial gearboxes and mill applications.

How do I select the right size for my application?

Selecting the right size requires accurate measurement of the shaft and housing bores. You can use our detailed taper roller bearing dimensions chart to match your measurements with the correct bearing specifications. It is also important to consider the load requirements (both radial and axial) and the operating speed of the application. If you need assistance, our team can help you find the perfect bearing based on your specific needs.

Are TS (Tapered Single Roller Bearings) (Metric) easy to install and maintain?

Yes, TS (Tapered Single Roller Bearings) (Metric) are designed with separable components (cone and cup), which significantly simplifies their installation and removal. This feature also makes inspection and maintenance procedures more straightforward. Proper lubrication is crucial for their longevity, and regular checks for wear or damage are recommended. Adhering to manufacturer guidelines for mounting and lubrication will ensure optimal performance and extend the lifespan of these bearings.