Home / Product / Roller Bearings / Tapered Roller Bearings / Single Tapered Roller Bearings / TS (Single Row Tapered Roller Bearings) (Imperial)

Our TS (Tapered Single Roller Bearings) (Imperial) are engineered for superior performance and reliability. These single row tapered roller bearings are designed to accommodate combined loads, meaning they can handle both significant radial forces and substantial axial (thrust) loads. The unique conical bearing design, consisting of a cone (inner ring), cup (outer ring), tapered rollers, and a cage, ensures optimal load distribution and reduced friction. Ideal for applications requiring high precision and durability, our imperial tapered roller bearings are a cornerstone in various industries, from automotive to heavy machinery.

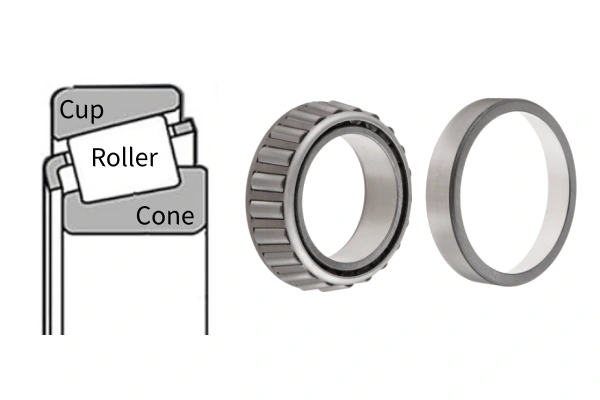

The Unique Design of Tapered Roller Bearings

Tapered roller bearings feature a cone and cup design. The cone is the inner ring assembly. It includes the rollers and the cage. The cup is the outer ring. These parts are designed to be separable. This allows for easier mounting and dismounting. The tapered geometry ensures that true rolling motion occurs between the rollers and the races, minimizing friction and wear.

Our imperial single tapered roller bearings are manufactured to tight tolerances. This ensures high precision and reliability. The design helps distribute loads evenly across the contact area. This reduces stress on individual components. It also prolongs the bearing’s service life. We focus on providing bearings that offer a long life cycle.

Benefits of TS (Tapered Single) Bearings in Imperial Sizes

Using imperial-sized bearings provides many advantages for specific applications. Many older machines and systems were built using imperial units. Our imperial single tapered roller bearings are perfect for these applications. They provide a direct fit and avoid the need for complex conversions or custom parts. This saves time and money.

These conical bearings are known for their high load-carrying capacity. They can support heavy radial loads. They also handle significant axial thrust from one direction. This makes them ideal for demanding applications. Examples include wheel bearings in vehicles and gearboxes in industrial equipment. Our bearings provide a reliable solution for these critical components.

Long Service Life and Reliable Performance

The tapered design of TS single roller bearings reduces stress concentration and minimizes friction, leading to less heat generation and longer operational life. These features make them suitable for high-speed and high-load environments.

Additionally, TFL ensures strict quality control for every bearing produced. From material selection to final inspection, each step is optimized for durability and consistency in performance, making our tapered roller bearings a trusted solution for demanding industrial sectors.

FREQUENTLY ASKED QUESTIONS

What are the main differences between imperial and metric tapered roller bearings?

The primary difference lies in the measurement system used for their dimensions. Imperial bearings are sized in inches, while metric bearings are sized in millimeters. While their basic function and design are similar, they are not interchangeable. It is crucial to select the correct type for your equipment to ensure proper fit and performance. Using an imperial bearing in a metric system or vice versa can lead to premature failure and costly damage.

How do I properly install a tapered roller bearing?

Proper installation is essential for the long life of any tapered roller bearing. The process typically involves pressing the cone onto the shaft and the cup into the housing. It is important to apply force only to the ring being pressed to avoid damaging the bearing. Proper lubrication is also critical. Always consult the manufacturer's instructions for specific procedures and required tools. Incorrect installation can lead to early bearing failure and reduced performance.

What are the main benefits of using single row tapered roller bearings?

Single row tapered roller bearings offer several key benefits. They excel at accommodating heavy combined radial and axial loads due to their unique geometry. Their separable design, with the cone assembly and cup, allows for easier mounting and inspection, which can simplify maintenance. Furthermore, these precision conical bearings provide excellent stiffness and can be adjusted during installation to achieve specific operating clearances, optimizing performance for a given application. This adaptability makes them a versatile solution for many demanding industrial applications.

How important is lubrication for the longevity of TS (Imperial) bearings?

Lubrication is critically important for the longevity and reliable operation of TS (Imperial) bearings. Proper lubrication reduces friction between the rolling elements and raceways, preventing premature wear and heat buildup. It also forms a protective barrier against corrosion and contamination. Without adequate and appropriate lubrication, the bearing can quickly overheat, seize, and fail, leading to costly downtime and repairs. Following the manufacturer's recommendations for lubricant type and relubrication intervals is essential to ensure maximum service life for your imperial tapered roller bearings.