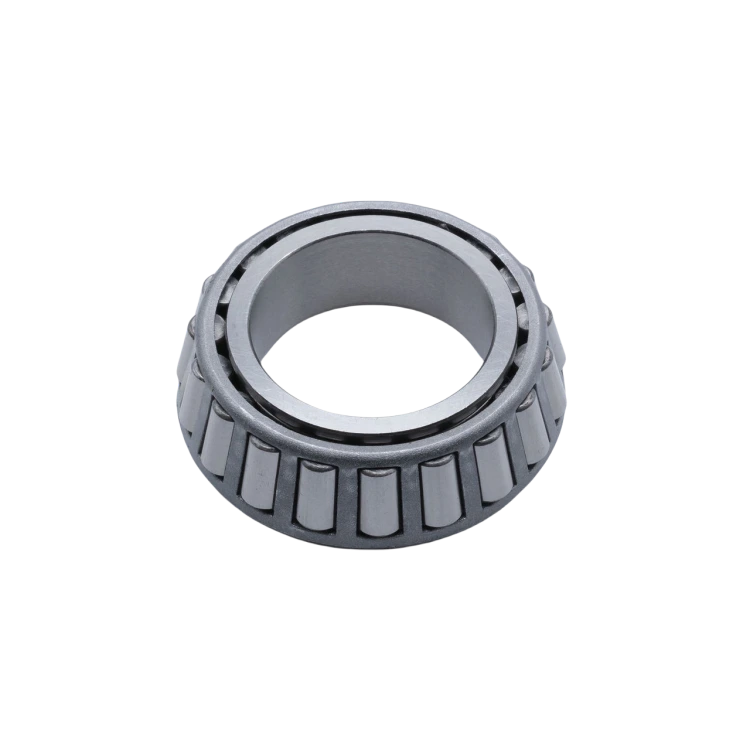

Single Tapered Roller Bearings

Single Tapered Roller Bearings are engineered to handle combined radial and axial loads with exceptional reliability. Designed with one row of tapered rollers, they offer superior load-carrying performance, low friction, and adjustable clearance.

Home / Product / Roller Bearings / Tapered Roller Bearings / Single Tapered Roller Bearings

Why Are TFL Roller Bearings Suitable for You?

At TFL Bearings, our Single Tapered Roller Bearings are manufactured with precision-machined components and high-grade steel. We offer tight dimensional control, extended service life, and seamless interchangeability across TS, TSF, and sealed types. Our KT Series and custom options meet the most demanding application requirements.

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

Roller Bearings Category

Roller Bearings Category

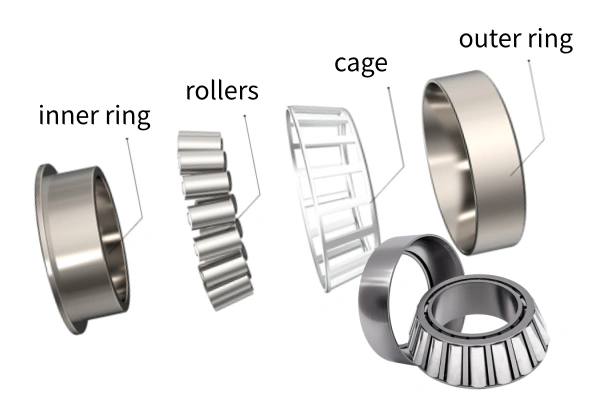

Tapered Roller Bearing Design and Components

A Single Tapered Roller Bearing consists of a cone assembly (inner ring + rollers + cage) and a separate cup (outer ring). The tapered geometry allows it to carry both radial and axial loads in a single direction.

The adjustable internal clearance makes it highly adaptable, offering smooth operation and high rigidity. Variants like TS (Imperial/Metric) and TSF with flange offer versatile installation options across industrial systems.

Application Scenarios and Performance Benefits

Tapered roller bearings are ideal for automotive axles, gearboxes, construction equipment, and heavy-duty machinery. The low friction design enables better fuel efficiency and longer maintenance intervals.

Models like the Sealed Tapered Roller Bearings provide added protection against dust and moisture, extending the lifespan and reducing downtime. Our KT Series is optimized for high-speed and compact environments, making it a top choice in robotics and automation.

Dimensional Options and Precision Fit

Single tapered roller bearings are available in a wide range of imperial and metric dimensions. TFL provides bearing size charts and taper roller bearing dimension charts to help engineers select the right configuration for each system.

Each unit is precision-ground for a tight tolerance fit, ensuring smooth torque transfer, minimal noise, and low heat generation. We also offer options for sealed thrust bearings and miniature bearings for more specialized needs.

APPLICATION AREA

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

Industrial Bearings

The Industrial Machinery & Manufacturing sector forms the backbone of modern production, encompass

Railway Bearings

Railway Bearings Locomotives, passenger cars, freight wagons (railcar), and track maintenance equipmen

Automotive Bearings

Automotive Bearings In the demanding environment of an automobile, automotive bearings must operate re

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

Market-proven with over 28 million bearings successfully delivered, and certified under multiple quality management systems, including ISO 9001.

PRICE

By integrating and leveraging China’s robust raw material supply chain, TFL is able to strictly control production costs, thereby offering highly competitive product prices.

FAST DELIVERY

With a vast inventory of over a million bearings, TFL offers solid assurance for your procurement needs. Common bearing models are ready for dispatch within just 48 hours.

FREQUENTLY ASKED QUESTIONS

What is the difference between a single tapered roller bearing and a double tapered roller bearing?

A single tapered roller bearing is designed to handle a combination of radial and axial loads from a single direction. A double tapered roller bearing is essentially two single bearings arranged back-to-back or face-to-face within a single unit. This design allows them to handle heavier radial loads and axial loads from both directions, making them suitable for applications with bidirectional thrust requirements.

How do I know if I need a tapered roller bearing or a ball bearing?

The choice depends on your application's load requirements. Ball bearings are best for light to moderate radial loads and high-speed applications. Tapered roller bearings, on the other hand, are specifically engineered for heavy radial and axial loads. If your application involves significant thrust forces or a combination of radial and axial loads, a tapered roller bearing is the more robust and reliable choice.

What are the main components of a tapered roller bearing?

A standard single tapered roller bearing consists of two main parts: the cone and the cup. The cone is the inner ring assembly, which includes the inner ring, the tapered rollers, and a cage to hold the rollers. The cup is the outer ring. These two components are separable, which is a key feature of the design and allows for easier installation and maintenance.

How do I find the correct size for my application?

Finding the correct size is crucial. You'll need to know the bore diameter (the inner diameter), the outer diameter of the cup, and the total width of the bearing. Our website provides a tapered roller bearing dimensions chart and a bearing search by size tool to help you find the exact specifications you need. It's also recommended to consult the original equipment manual or a professional to ensure the correct bearing is selected for your specific application.