Tapered Roller Bearings – Precision Under Heavy Loads

Designed for demanding applications, tapered roller bearings offer high load capacity and excellent durability. With their tapered raceways and rollers, they minimize friction and support both radial and thrust forces, ensuring reliable performance in automotive and industrial sectors.

Home / Product / Roller Bearings / Tapered Roller Bearings

Why Choose TFL Tapered Roller Bearings?

TFL Bearings offers reliable performance, competitive pricing, and precision-engineered tapered roller bearings. Every product undergoes strict quality control to ensure consistency and performance. Whether you need single row, double row, or four-row tapered roller bearings, TFL provides tailored solutions with fast delivery and technical support.

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

Roller Bearings Category

Roller Bearings Category

Single and Double Row Tapered Roller Bearings

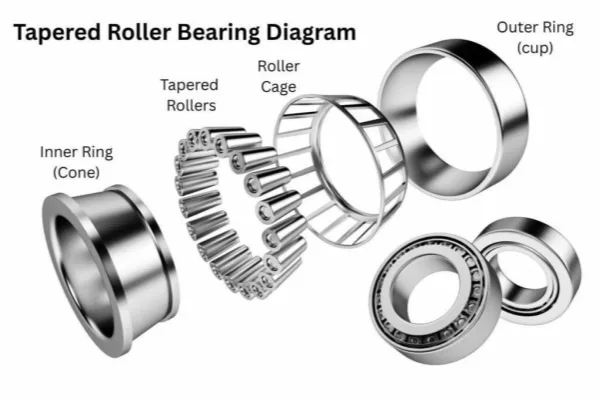

Single row tapered roller bearings are the most common and versatile type in the tapered roller family. These bearings consist of one inner ring, one outer ring, and tapered rollers arranged between them. They are capable of handling radial loads and axial loads in one direction. In applications where axial loads need to be supported from both directions, they must be paired with another bearing. Typical use cases include automotive wheel hubs, gearboxes, and agricultural machinery.

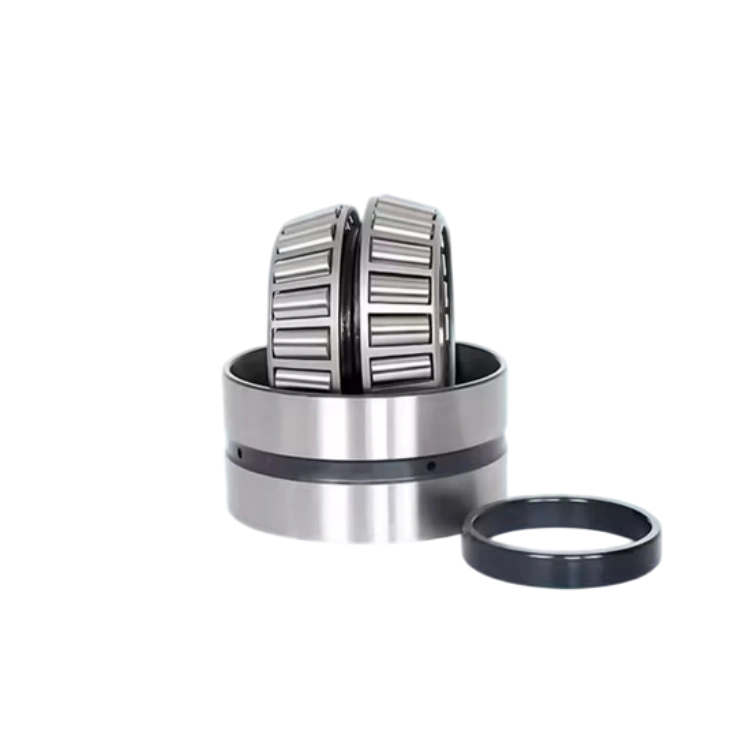

Double row tapered roller bearings, on the other hand, integrate two rows of rollers into a single unit. This allows the bearing to withstand axial loads in both directions, while also increasing the radial load capacity. These bearings are ideal for heavy-duty applications like mining equipment, steel rolling machines, and construction vehicles. The two-row design also improves system rigidity and alignment under challenging working conditions.

TQO and MTR Matched Bearings

TQO bearings, also known as four-row tapered roller bearings, are engineered for extreme radial and axial load conditions. Each bearing consists of four rows of rollers arranged to provide maximum support. They are primarily used in applications such as rolling mills, railway axle boxes, and large gearboxes, where high rigidity, continuous operation, and load-bearing capacity are essential.

The four-row structure enables these bearings to distribute the load across a larger contact area, reducing internal stress and wear. Despite their size, TQO bearings are precisely machined to offer low vibration and high running accuracy. They are especially suited for applications with slow speeds but very high static or dynamic loads.

MTR bearings, or matched tapered roller bearings, are a set of two or more bearings designed and manufactured to work together in a predefined arrangement. They are pre-adjusted to optimize internal clearance and preload, ensuring perfect alignment, even load distribution, and easy assembly. These are widely used in axle systems, industrial reducers, and precision transmission systems.

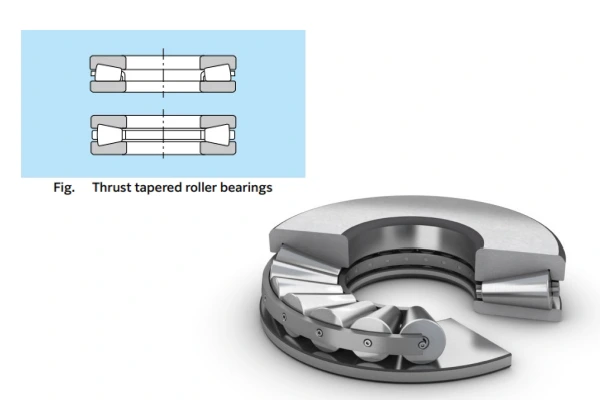

Thrust Tapered Roller Bearings

Thrust tapered roller bearings are a specialized variant of tapered bearings designed exclusively to carry axial loads. Unlike radial designs, the thrust type focuses on resisting force along the shaft axis. The rollers are arranged at a steep angle to handle high thrust forces effectively while maintaining excellent alignment and minimal deflection.

These bearings are ideal for heavy axial load applications such as crane swivels, vertical gearboxes, hydraulic cylinder bases, and lifting jacks. Their ability to maintain stability under load makes them indispensable in vertical or tilted installations where traditional bearings may fail.

TFL manufactures thrust tapered roller bearings with high-precision raceways and optimized roller geometry, ensuring reduced heat generation and wear. The materials used undergo heat treatment to improve fatigue strength and resistance to deformation under peak loads. For customers requiring long service life with minimal maintenance, these bearings are the perfect choice.

APPLICATION AREA

Medical Bearings

Medical Bearings The Medical Technology sector develops advanced equipment for diagnostics, treatment,

Marine Bearings

Marine Bearings The Marine Industry operates in one of the planet’s most demanding environments.

Agricultural Bearings

Agricultural Bearings The Agricultural Machinery sector is the backbone of global food production, uti

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

Market-proven with over 28 million bearings successfully delivered, and certified under multiple quality management systems, including ISO 9001.

PRICE

By integrating and leveraging China’s robust raw material supply chain, TFL is able to strictly control production costs, thereby offering highly competitive product prices.

FAST DELIVERY

With a vast inventory of over a million bearings, TFL offers solid assurance for your procurement needs. Common bearing models are ready for dispatch within just 48 hours.

FREQUENTLY ASKED QUESTIONS

What is the main difference between tapered roller bearings and other roller bearings?

The key difference is their ability to handle both radial and axial loads simultaneously. Unlike cylindrical roller bearings which are primarily for radial loads, or ball thrust bearings which handle only axial loads, the conical design of tapered roller bearings allows them to manage combined forces effectively. This makes them a superior choice for heavy-duty applications like vehicle hubs and transmissions.

Can tapered roller bearings be used in high-speed applications?

While tapered roller bearings are excellent for handling heavy loads, their design with sliding contact between the roller ends and the cone rib can generate more heat than ball bearings at very high speeds. They are generally better suited for moderate to high-speed applications. For extreme precision and high speeds, precision tapered roller bearings are specifically engineered to minimize friction and heat, making them a suitable option.

Are sealed tapered roller bearings available from TFL?

Yes. TFL offers sealed tapered roller bearings that combine the traditional high-load capability of open bearings with the added protection of sealing technology. These seals prevent dust, debris, and moisture from entering the bearing, which is critical in applications such as agriculture, mining, or construction. Sealed designs also help retain lubrication, reducing maintenance intervals and improving operational reliability in dirty or remote environments. TFL's sealed series is ideal for customers who need long-lasting performance with reduced service demands.

How do I choose the right taper bearing size?

Selecting the right tapered roller bearing size involves several factors: shaft diameter, housing dimensions, load ratings, speed, and application environment. TFL provides a comprehensive taper roller bearing dimensions chart to help users quickly match requirements. If you're unsure, our technical team can provide assistance based on operating conditions like temperature, vibration, and contamination. It’s important to consider whether your application requires single row, double row, or four-row bearings, and to verify if a sealed or open type is better suited. A proper fit ensures optimal bearing life and efficiency.