Home / Product / Roller Bearings / Needle Roller Bearings / Needle Roller And Cage Assemblies

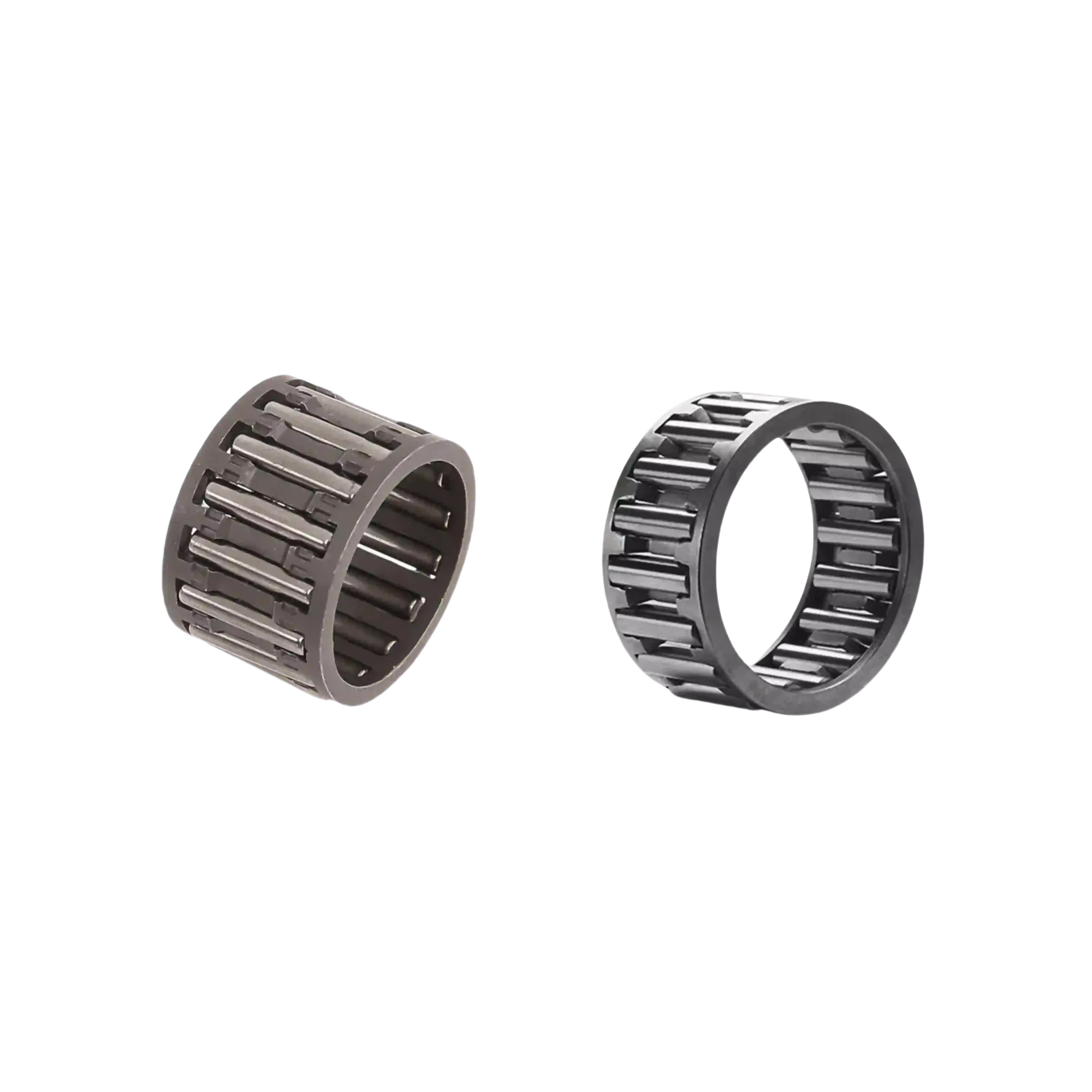

Needle Roller and Cage Assemblies

Needle roller and cage assemblies are high-performance components designed for applications requiring high load capacity in a compact space. These needle bearings feature thin cylindrical rollers and a precise bearing cage that ensures accurate roller guidance and low friction. Unlike loose needle rollers, the cage structure ensures uniform load distribution, reduces friction heat by up to 40%, and prevents roller skewing during high-speed operation. TFL’s assemblies undergo rigorous testing to exceed ISO 9001 standards.

Loading...

Total 260 Results

Part Number

Bore Dia

Outer Dia

Width

System of Measurement

Construction

Series

Cage Material

Dynamic Radial Load

Static Radial Load

Max Speed

Weight

K100X108X27

100 mm

108 mm

27 mm

Metric

Single Row

K Series

Steel

12825 lbf

32175 lbf

4700 rpm

185 g

K100X108X30

100 mm

108 mm

30 mm

Metric

Single Row

K Series

Steel

15975 lbf

42300 lbf

4700 rpm

180 g

K105X112X21

105 mm

112 mm

21 mm

Metric

Single Row

K Series

Steel

10688 lbf

28575 lbf

4500 rpm

129 g

K110X117X24

110 mm

117 mm

24 mm

Metric

Single Row

K Series

Steel

12600 lbf

35550 lbf

4300 rpm

172 g

K110X118X30

110 mm

118 mm

30 mm

Metric

Single Row

K Series

Steel

17550 lbf

49275 lbf

4300 rpm

217 g

K115X123X27

115 mm

123 mm

27 mm

Metric

Single Row

K Series

Steel

14175 lbf

38250 lbf

4100 rpm

200 g

K120X127X24

120 mm

127 mm

24 mm

Metric

Single Row

K Series

Steel

13275 lbf

39150 lbf

4000 rpm

165 g

K125X133X35

125 mm

133 mm

35 mm

Metric

Single Row

K Series

Steel

19350 lbf

58500 lbf

3800 rpm

275 g

K130X137X24

130 mm

137 mm

24 mm

Metric

Single Row

K Series

Steel

13725 lbf

41850 lbf

3700 rpm

170 g

K135X143X35

135 mm

143 mm

35 mm

Metric

Single Row

K Series

Steel

20475 lbf

65250 lbf

3600 rpm

300 g

K145X153X26

145 mm

153 mm

26 mm

Metric

Single Row

K Series

Steel

16650 lbf

50625 lbf

3300 rpm

262 g

K150X160X46

150 mm

160 mm

46 mm

Metric

Single Row

K Series

Steel

33075 lbf

105750 lbf

3200 rpm

570 g

K155X163X26

155 mm

163 mm

26 mm

Metric

Single Row

K Series

Steel

16875 lbf

53100 lbf

3100 rpm

265 g

K160X170X46

160 mm

170 mm

46 mm

Metric

Single Row

K Series

Steel

34200 lbf

114750 lbf

3000 rpm

550 g

Enhanced Load Capacity and Compact Design

Needle roller and cage assemblies are renowned for their impressive load-carrying capabilities within an incredibly small cross-section. The large number of needle rollers in contact with the raceway distributes the load over a greater area, allowing these needle bearings to withstand significant radial forces. This design is not only space-efficient but also contributes to the longevity of the assembly by reducing localized stress.

The ability of needle roller bearings to handle heavy radial loads in tight spaces makes them a go-to solution where conventional roller bearings or ball bearings might be too bulky. This compact nature is particularly beneficial in applications with limited mounting space, such as automotive transmissions, industrial robotics, and various power tools.

Versatility in Application and Design Adaptability

The adaptability of needle roller and cage assemblies extends across a wide range of industries and machine designs. From heavy-duty construction equipment and agricultural machinery to intricate medical devices and precise robotics, these roller bearing assemblies provide reliable and efficient operation. They are frequently integrated into gearboxes, pumps, engine components, and various power transmission systems where high speed, precision, and robust performance are critical.

Furthermore, their modular design allows for flexibility: they can operate directly on a hardened shaft or with an inner ring, providing design engineers with options to optimize their assemblies. For applications requiring axial load support, needle roller thrust bearings are also available, seamlessly complementing the radial load capabilities of standard needle roller bearings.

Precision Manufacturing and Material Excellence

Our needle roller and cage assemblies are a testament to precision engineering and material science. TFL Bearings utilizes only high-grade bearing steel for the needle rollers, ensuring superior hardness, wear resistance, and fatigue life.

The bearing cage is crafted from durable materials like steel or specialized plastics, designed to precisely guide and space the needle rollers, minimizing friction and heat generation. The meticulous manufacturing of each needle roller bearing component, from the precision needle rollers to the robust cage, guarantees consistent quality, exceptional reliability, and extended service life.

We offer a comprehensive range of needle roller bearing sizes and provide detailed needle roller bearing dimensions charts to meet the exact specifications of diverse applications, ensuring our customers find the perfect fit for their needs. As a leading needle roller bearing manufacturer, we stand by the quality of our bearing assembly.

FREQUENTLY ASKED QUESTIONS

What is the main difference between a needle roller bearing and a ball bearing?

The primary difference lies in their rolling elements. Needle roller bearings use long, thin needle rollers, allowing for higher radial load capacity in a smaller space compared to ball bearings, which use spherical balls. This makes needle vs ball bearing selection crucial for specific design constraints, especially when space is limited and high radial loads are present.

Where are needle roller and cage assemblies typically used?

Needle roller and cage assemblies are widely used in applications requiring high load capacity within a compact design. Common uses include automotive transmissions, air conditioning compressors, steering systems, power tools, agricultural machinery, and various industrial gearboxes. They are also found in more specialized equipment such as fitness machines and office equipment.

How do I determine the correct needle roller bearing size for my application?

Selecting the correct needle roller bearing size involves considering several critical factors: the shaft diameter, housing bore, operating loads (both radial and axial), desired speed, and ambient temperature. We provide detailed needle roller bearing dimensions charts and comprehensive technical support to assist you in choosing the optimal needle bearing that perfectly matches your specific application requirements.

Are needle roller thrust bearings different from radial needle roller bearings?

Yes, needle roller thrust bearings support high axial loads in one direction, while radial needle roller bearings handle high radial loads. TFL provides both types for various industrial applications.