Home / Product / Roller Bearings / Needle Roller Bearings / Drawn Cup Needle Roller Bearings

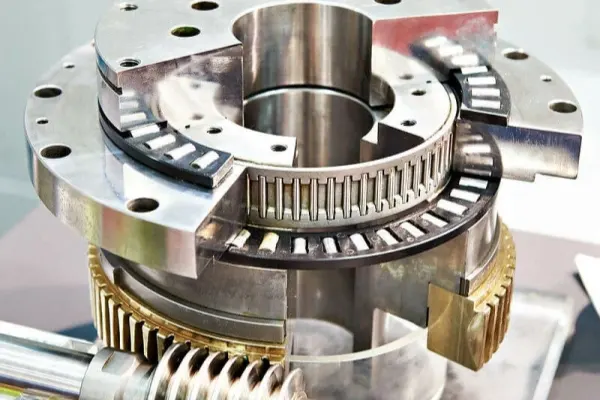

Drawn Cup Needle Roller Bearings

Drawn cup needle roller bearings feature thin-walled outer rings made of drawn steel. They are compact, lightweight, and ideal for applications with limited space and high radial loads. Available with or without inner rings, these needle roller bearings offer high performance in demanding conditions.

Loading...

Total 471 Results

Part Number

Interchangeable

Bore Dia

Outer Dia

Width

System of Measurement

Construction

Seal Type

Series

Dynamic Radial Load

Static Radial Load

HK5024-2RS

INA

50 mm

58 mm

24 mm

Metric

Single Row

Double Seal

Open End

6969 lbf

14163 lbf

HK5025

INA

50 mm

58 mm

25 mm

Metric

Single Row

Open

Open End

8655 lbf

18884 lbf

HN5020

INA

50 mm

58 mm

20 mm

Metric

Single Row

Open

Full Complement

10004 lbf

26752 lbf

HN5025

INA

50 mm

58 mm

25 mm

Metric

Single Row

Open

Full Complement

1214 lbf

34171 lbf

HK5520

INA

55 mm

63 mm

20 mm

Metric

Single Row

Open

Open End

7081 lbf

15062 lbf

HK5528

INA

55 mm

63 mm

28 mm

Metric

Single Row

Open

Open End

9892 lbf

23155 lbf

HK6012

INA

60 mm

68 mm

12 mm

Metric

Single Row

Open

Open End

3912 lbf

7194 lbf

HK6020

INA

60 mm

68 mm

20 mm

Metric

Single Row

Open

Open End

7531 lbf

16861 lbf

HK6032

INA

60 mm

68 mm

32 mm

Metric

Single Row

Open

Open End

11915 lbf

30349 lbf

Types of Drawn Cup Needle Roller Bearings

Types of Drawn Cup Needle Roller Bearings

Drawn cup needle roller bearings are available in two primary types: caged and full complement.

- The caged roller bearing uses a needle cage to maintain roller spacing. This design minimizes friction, supports higher rotational speeds, and extends bearing life due to reduced heat buildup.

- In contrast, the full complement needle bearing contains the maximum number of needle bearing needles. Without a cage, these bearings offer superior radial load capacity but are best suited for lower-speed applications due to higher internal friction.

Some models include open ends, while others come with closed ends for thrust resistance. TFL Bearings provides all major styles to meet specific operating conditions. Our drawn cup bearings can also be tailored for applications that require sealed designs or special materials.

Applications in Industrial Equipment

TFL’s industrial bearings, especially drawn cup needle roller bearings, are a preferred solution in compact and high-load environments. Common use cases include:

- Automotive transmissions and steering systems, where space is limited but torque transmission requires strong radial support.

- Power tools such as drills and grinders, where weight and rotational efficiency are key.

- Agricultural equipment, like harvesters and balers, where the bearings must handle dust, vibration, and shock loads.

- Construction machinery and hydraulic systems, which benefit from the bearings’ low-profile structure and high load tolerance.

These bearings are also essential in two-stroke engines, pumps, and small gearboxes. Their compact form factor allows for design flexibility without compromising durability or reliability.

Advantages over Other Needle Bearings

Drawn cup bearings offer several significant advantages over other types of needle roller bearings:

- Compact structure: The drawn outer shell eliminates the need for a thick housing, making them ideal for lightweight or portable equipment.

- Cost-efficiency: Due to simpler manufacturing processes and reduced material usage, these bearings are more economical without sacrificing performance.

- Easy installation: These bearings can be press-fitted directly into the housing bore, requiring no additional fasteners or components.

- Flexible design options: TFL offers variants with or without inner rings, open or closed ends, and different lubrication methods (greased, dry, or sealed).

These characteristics make them the go-to choice in scenarios where standard bearings may be too bulky or costly.

FREQUENTLY ASKED QUESTIONS

What are drawn cup needle roller bearings?

Drawn cup needle roller bearings are thin-walled bearings with needle rollers and a bearing cage, designed for high radial loads in compact spaces.

How to choose between caged and full complement types?

If your application requires higher speeds and less friction, choose a caged roller bearing. The cage keeps the needle bearing needles evenly spaced and allows smoother rotation. If you need maximum load support in low-speed applications, a full complement type—with more needles and no cage—is better.

Can drawn cup needle bearings be used without inner rings?

Yes. Many drawn cup needle roller bearings are designed to be used directly on hardened and ground shafts, eliminating the need for an inner ring. This simplifies the assembly and saves axial space while maintaining precision and performance.

Do drawn cup needle bearings require lubrication?

Yes. Proper lubrication is critical to prevent wear and extend the bearing's lifespan. TFL Bearings offers both greased and ungreased drawn cup needle roller bearings, depending on your specific application. Ensure regular maintenance or sealed options for demanding environments.

Are drawn cup needle bearings easy to install?

Yes. Their compact design and thin outer ring make installation easier, especially in housings where space is limited. They can be press-fitted directly into the housing without special tools, reducing labor and assembly time.