Home / Product / Roller Bearings / Cylindrical Roller Bearings / High-Capacity Cylindrical Roller Bearings

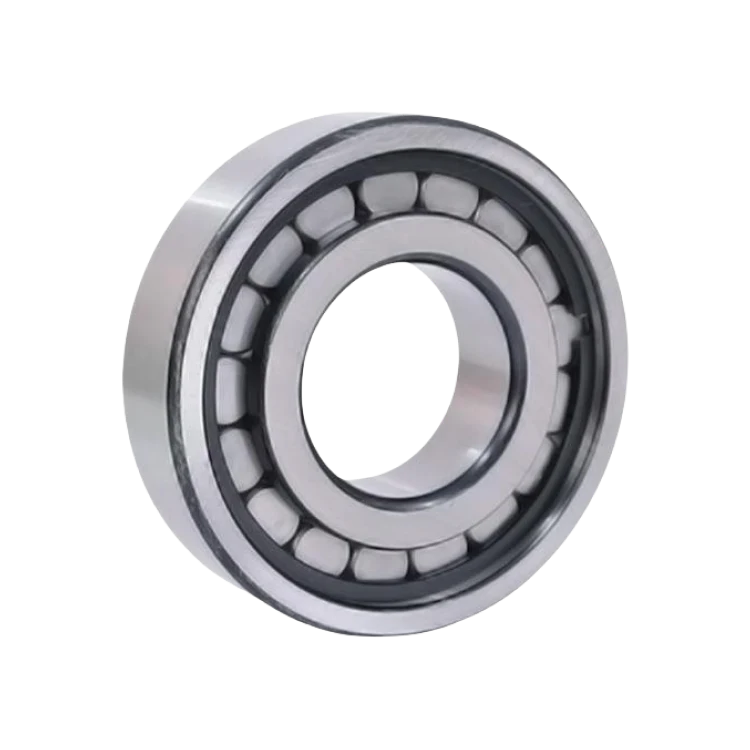

High-Capacity Cylindrical Roller Bearings

High-capacity cylindrical roller bearings are engineered to handle higher radial loads compared to standard designs. These bearings are ideal for heavy machinery, wind turbines, and industrial equipment. Their ability to distribute loads evenly ensures optimal performance and extended service life.

Loading...

Total 41 Results

Part Number

Interchangeable

System of Measurement

For Load Direction

Bore Dia

Outer Dia

Width

Dynamic Radial Load

Static Radial Load

Weight

NCF 2338 ECJB/PEX

SKF

Metric

Combined

190 mm

400 mm

132 mm

504000 lbf

618750 lbf

78 kg

NUH 2238 ECMH

SKF

Metric

Combined

190 mm

340 mm

92 mm

297000 lbf

396000 lbf

36 kg

NUH 2338 ECMH/PEX

SKF

Metric

Combined

190 mm

400 mm

132 mm

504000 lbf

618750 lbf

78.6 kg

NCF 2240 ECJB

SKF

Metric

Combined

200 mm

360 mm

98 mm

328500 lbf

450000 lbf

43 kg

NCF 2340 ECJB/PEX

SKF

Metric

Combined

200 mm

420 mm

138 mm

573750 lbf

720000 lbf

91.5 kg

NUH 2240 ECMH

SKF

Metric

Combined

200 mm

360 mm

98 mm

328500 lbf

450000 lbf

43.4 kg

NUH 2340 ECMH/PEX

SKF

Metric

Combined

200 mm

420 mm

138 mm

573750 lbf

720000 lbf

92.7 kg

NCF 2244 ECJB/PEX

SKF

Metric

Combined

220 mm

400 mm

108 mm

450000 lbf

585000 lbf

58.5 kg

NCF 2344 ECJB

SKF

Metric

Combined

220 mm

460 mm

145 mm

564750 lbf

821250 lbf

115 kg

NUH 2244 ECMH/PEX

SKF

Metric

Combined

220 mm

400 mm

108 mm

450000 lbf

585000 lbf

58.8 kg

NUH 2344 ECMH/PEX

SKF

Metric

Combined

220 mm

460 mm

145 mm

652500 lbf

821250 lbf

116 kg

NUH 2248 ECMH/PEX

SKF

Metric

Combined

240 mm

440 mm

120 mm

513000 lbf

686250 lbf

80 kg

NUH 2348 ECMH/PEX

SKF

Metric

Combined

240 mm

500 mm

155 mm

708750 lbf

900000 lbf

143 kg

Ultimate Carrying Capacity

In modern industry, the demands for compact design and performance improvement are getting higher and higher, which poses a severe challenge to the bearing field. Especially in terms of load capacity, users are more inclined to enhance the performance of bearings without changing their dimensions.

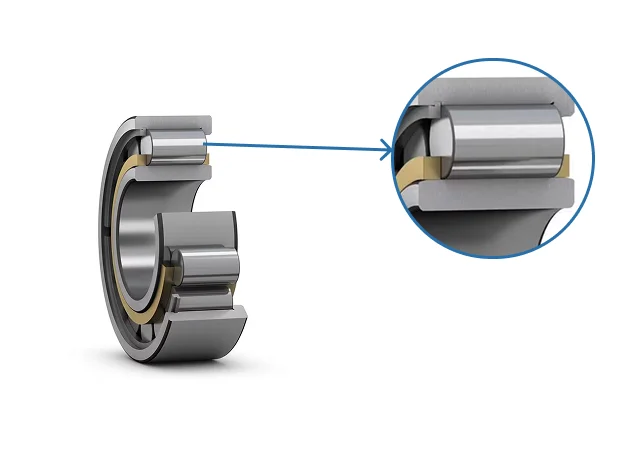

TFL’s high-capacity cylindrical roller bearings have significantly improved the load-carrying capacity and service life of bearings by optimizing the structure and materials of the bearings. Take the cage design as an example. The high-load bearing adopts a thinner and stronger cage, allowing the bearing to accommodate more and larger rollers. While achieving the load-carrying capacity, it can also meet the requirements of rotational speed.

High Load Capacity Brings You High Returns.

High-load roller bearings do not merely become “stronger” by enhancing their own strength, but also simultaneously improve the overall operational efficiency of the bearings, making the transmission of loads within the bearings more efficient.

This optimization makes the bearings more durable and does not reduce their lifespan even when they are under high-load conditions. For applications that require heavy loads, these bearings can significantly reduce maintenance and replacement costs, minimize downtime, and provide you with a more stable usage experience and higher returns.

Overload Application Specialization

Due to the extremely superior load-carrying capacity of this type of bearing, its suitable application scenarios are clearly targeted at large industrial equipment with a strong demand for heavy loads, such as:

- Industrial gearboxes: Withstand huge gear meshing forces to ensure smooth transmission.

- Wind turbines: Bear the gear meshing loads in the turbine gearboxes or be used in conjunction with self-aligning roller bearings in the main shaft support.

- Mining machinery: Equipment like crushers and vibrating screens that are constantly exposed to heavy loads and shocks.

- Large motors and pumps: Support the rotor and withstand high radial forces.

FREQUENTLY ASKED QUESTIONS

How much higher is the load-carrying capacity of high-capacity cylindrical roller bearings compared to standard models?

The specific improvement extent depends on the specific design (such as full rollers or optimized cages) and size series.

Generally, its radial dynamic and static load capacity can be 20% to 40% higher than that of standard bearings of the same size. If you need detailed selection suggestions, contact us. TFL offers high-quality and high-load cylindrical roller bearings and will provide you with comprehensive selection and purchase advice.

Are there any disadvantages to be aware of when using high-load bearings?

The main trade-off lies in the max speed. Especially for the full complement design, due to the direct contact between rollers which causes friction, its maximum speed is usually lower than that of bearings with cages.

When selecting, it is necessary to balance the load-carrying capacity and speed requirements. For heavy-duty applications with high speed demands, it is recommended to choose high-load models with optimized cages (such as ECP type).

Are there any special requirements for lubrication of high-load bearings?

Due to their higher load-carrying capacity, especially for full-roller bearings, more heat is generated by the friction between the rollers. Therefore, it is crucial to ensure adequate and clean lubrication. It is recommended to use grease or oil with good extreme pressure (EP) performance to ensure the formation of a stable oil film under heavy loads.

What payment methods do you offer?

We support multiple payment methods, including Letter of Credit (L/C), bank transfer (T/T), and PayPal, providing convenient options for customers worldwide.