Home / Product / Roller Bearings / Cylindrical Roller Bearings / Double Row Full Complement Cylindrical Roller Bearings

Double Row Full Complement Cylindrical Roller Bearings

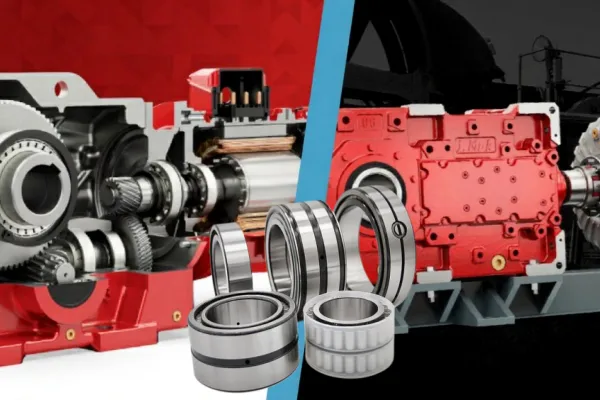

Explore TFL’s range of Double Row Full Complement Cylindrical Roller Bearings. These robust roller bearings are specifically designed for applications where extreme radial loads and shock loads are present. Unlike caged designs, our full complement bearings incorporate a maximum number of cylindrical rollers, directly contacting both the inner and outer rings. This innovative design significantly increases the bearing’s load-carrying capacity and rigidity, making them indispensable for heavy industrial machinery, rolling mills, and large gearboxes. Their design ensures optimal performance and extended bearing life even under the most challenging conditions.

Loading...

Total 191 Results

Part Number

Bore Dia

Outer Dia

Width

Seal Type

Shoulder Diameter Inner Ring

Raceway Diameter Outer Ring

Width Annular Lubrication Groove Outer Ring

Diameter Lubrication Hole (Outer Ring)

Weight

Outer Ring Width

Snap Ring Groove Diameter At Outer Ring

NNCF 5004 CV

20 mm

42 mm

30 mm

Open

28.4 mm

33.2 mm

4.5 mm

3 mm

0.2 kg

NNF 5004 ADB-2LSV

20 mm

42 mm

30 mm

Sealed

30.6 mm

6.5 mm

3.5 mm

0.193 kg

29 mm

40.2 mm

NNCF 5005 CV

25 mm

47 mm

30 mm

Open

34.5 mm

38.5 mm

4.5 mm

3 mm

0.225 kg

NNF 5005 ADB-2LSV

25 mm

47 mm

30 mm

Sealed

35.4 mm

6.5 mm

3.5 mm

0.224 kg

29 mm

45.2 mm

NNCF 5006 CV

30 mm

55 mm

34 mm

Open

40 mm

45.5 mm

4.5 mm

3 mm

0.348 kg

NNF 5006 ADB-2LSV

30 mm

55 mm

34 mm

Sealed

40.6 mm

7.5 mm

4.5 mm

0.351 kg

33 mm

53 mm

NNCF 5007 CV

35 mm

62 mm

36 mm

Open

45 mm

51.5 mm

4.5 mm

3 mm

0.455 kg

NNF 5007 ADB-2LSV

35 mm

62 mm

36 mm

Sealed

46.1 mm

7.5 mm

4.5 mm

0.45 kg

35 mm

60 mm

NNCF 5008 CV

40 mm

68 mm

38 mm

Open

50.5 mm

57.2 mm

4.5 mm

3 mm

0.554 kg

NNF 5008 ADB-2LSV

40 mm

68 mm

38 mm

Sealed

51.4 mm

7.5 mm

4.5 mm

0.529 kg

37 mm

65.8 mm

NNCF 5009 CV

45 mm

75 mm

40 mm

Open

55.3 mm

62.5 mm

4.5 mm

3 mm

0.684 kg

NNF 5009 ADB-2LSV

45 mm

75 mm

40 mm

Sealed

57 mm

8.5 mm

4.5 mm

0.69 kg

39 mm

72.8 mm

NNCF 5010 CV

50 mm

80 mm

40 mm

Open

59 mm

67.5 mm

4.5 mm

3 mm

0.747 kg

NNF 5010 ADB-2LSV

50 mm

80 mm

40 mm

Sealed

61.8 mm

8.5 mm

4.5 mm

0.714 kg

39 mm

77.8 mm

Design Advantages and Key Features

The absence of a cage in Double Row Full Complement Cylindrical Roller Bearings is a primary design advantage. This allows for a greater number of cylindrical rollers within the same envelope dimensions, directly increasing the dynamic and static load ratings. While the full complement design typically means a slightly lower speed limit compared to caged bearings, their strength in high-load, low-to-moderate speed environments is unmatched. These bearings are designed to handle significant axial displacement of the shaft relative to the housing, depending on the specific design (e.g., NU, NJ types for single row, adapted for double row configurations).

Our double row full complement cylindrical roller bearings offer superior shock resistance due to the robust contact surfaces and the sheer volume of rolling elements. This makes them ideal for environments where sudden impacts or vibrations are common. TFL offers comprehensive support for selecting the right cylindrical roller bearing specifications for your unique application.

Maximizing Radial Load Capacity and Rigidity

Double Row Full Complement Cylindrical Roller Bearings excel in applications demanding the highest possible radial load capacity. The full complement design means these bearings utilize every available space for cylindrical rollers. This maximizes the contact area between the rolling elements and the raceways. This engineering choice directly translates into superior load-carrying capabilities compared to single row cylindrical roller bearings or designs with a cage.

Furthermore, the robust construction of these cylindrical bearings contributes significantly to their exceptional rigidity. This rigidity is crucial in precision applications where minimizing deflection under heavy loads is paramount. Industries such as steel production, mining equipment, and heavy-duty gearboxes rely on the unwavering performance of these anti-friction bearings. TFL ensures that our double row cylindrical roller bearings meet stringent quality standards, providing reliable support for your machinery components.

Applications in Demanding Industrial Environments

Double Row Full Complement Cylindrical Roller Bearings are workhorses in some of the most challenging industrial settings. Their high load capacity and rigidity make them indispensable for applications such as rolling mills, where they withstand immense forces during metal forming processes. They are also widely used in heavy-duty gearboxes found in mining equipment, construction machinery, and wind turbines, ensuring reliable power transmission even under severe operating conditions.

Beyond these heavy industries, these precision bearings also find their place in large electric motors and other machinery components requiring robust support. The ability to manage both radial loads and, in some designs, limited axial loads, broadens their applicability. When considering where to buy bearings for such critical uses, TFL provides high-quality solutions, ensuring optimal bearing clearance and long-term performance. Our expertise helps you select the correct bearing dimensions for seamless bearing installation and efficient operation.

FREQUENTLY ASKED QUESTIONS

What is the main difference between single and double row full complement cylindrical roller bearings?

Double row bearings support higher radial loads and offer improved load distribution due to the additional row of rollers.

Where are double row full complement cylindrical roller bearings most commonly applied?

These bearings are primarily used in heavy-duty applications where the load is predominantly radial load and extremely high. Common examples include rolling mill bearings used in the steel industry, large gearbox bearings in industrial machinery components, heavy-duty pumps, and specialized electric motor bearings for high-power systems. Their high stiffness makes them indispensable in equipment requiring precision under extreme stress.

What is the best lubrication method for these bearings?

Oil bath or circulating oil systems are ideal for high-load, high-speed applications. Grease lubrication is also suitable for low to medium speeds.

Do these bearings come in different clearance options?

Yes. TFL offers standard and custom clearance options to suit various operating conditions and temperature ranges.