RU Crossed Roller Bearings: Compact Powerhouse for Precision

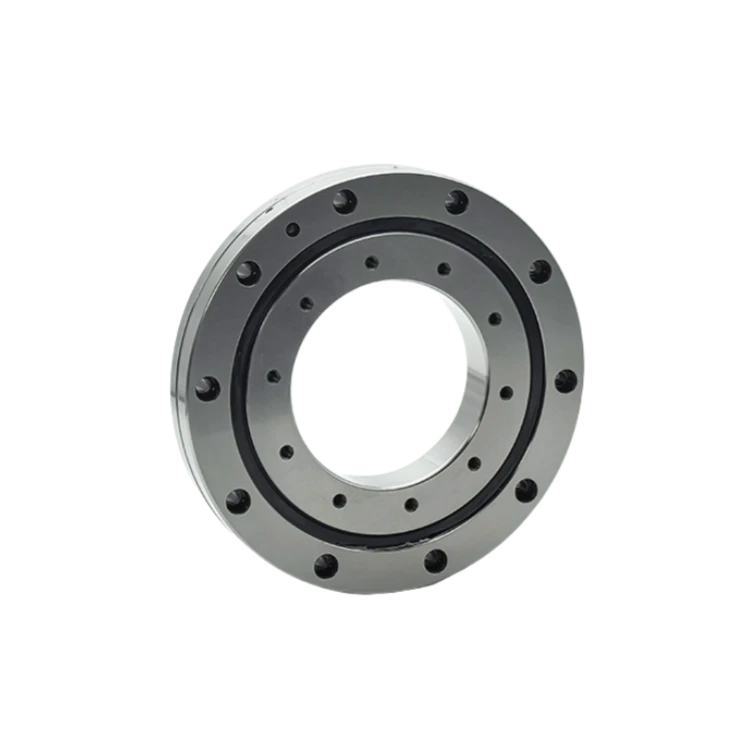

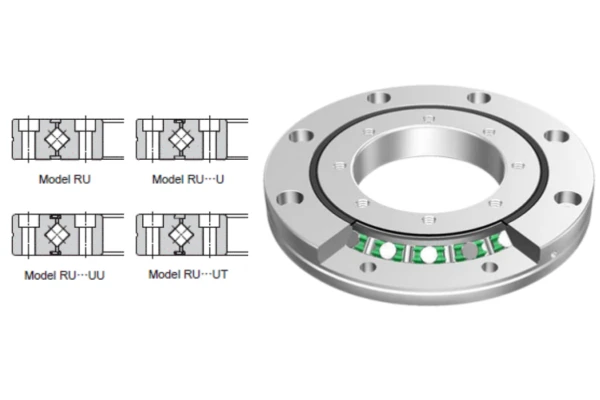

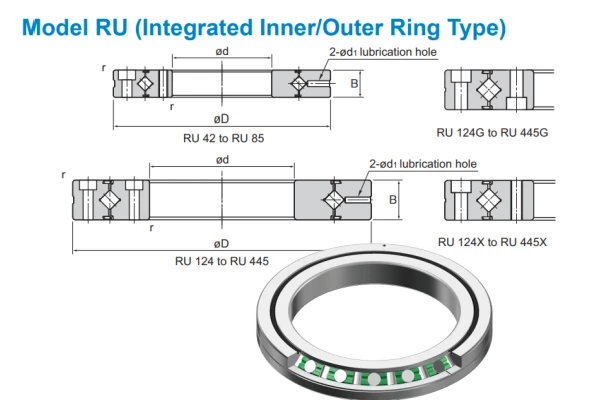

The Design of RU Crossed Roller Bearings

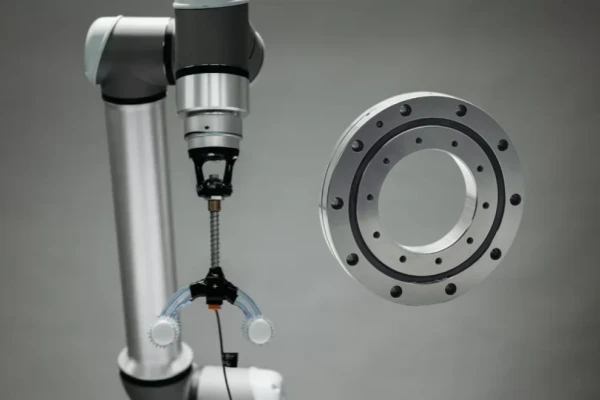

Key Applications of RU Crossed Roller Bearings

The Advantages of Using RU Crossed Roller Bearings

Compared to traditional ball bearings or other bearing types, RU crossed roller bearings offer significant advantages. Their single-bearing design simplifies machine architecture and reduces the overall footprint. The high rigidity and low friction translate to better positioning accuracy and a longer service life, which are critical for high-end equipment.

Furthermore, the pre-drilled mounting holes on the outer ring make installation simple and secure. The ability to handle multiple load types simultaneously eliminates the need for separate bearings for radial and axial loads. This streamlined design and superior performance make them a cost-effective and reliable choice for manufacturers seeking to optimize their machinery with high precision bearings.

FREQUENTLY ASKED QUESTIONS