Home / Product / Roller Bearings / Crossed Roller Bearings / RA Crossed Roller Bearings

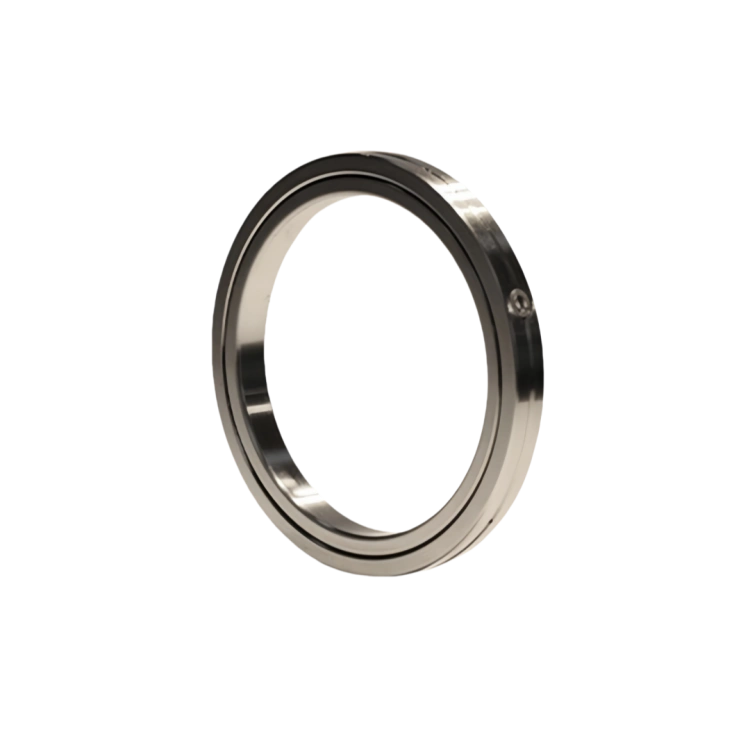

RA Crossed Roller Bearings

RA crossed roller bearings, also known as RA crossed cylindrical roller bearings, are a unique type of rolling bearing. Unlike traditional bearings that use a single row of rollers, RA bearings feature two rows of cylindrical rollers arranged at a 90-degree angle to each other. This innovative design allows them to handle significant axial and radial loads simultaneously. Their ultra-thin, separable outer ring and integrated inner ring construction make them exceptionally compact and lightweight. This thin-wall design effectively reduces the weight of the overall mechanism, making them an ideal choice for applications where space and weight are critical, such as in robotic arms and precision rotary tables.

Loading...

Total 64 Results

Part Number

Brand

Bore Dia

Outer Dia

Width

Greasing Hole(a)

Greasing Hole(b)

R(min)

Shoulder Height Ds(max)

Shoulder Height Dh(min)

Seal Type

Weight

RA15008CUU

TFL

150 mm

166 mm

8 mm

0.5 mm

153.5 mm

160.5 mm

Double Seal

0.2 Kg

RA15008UU

TFL

150 mm

166 mm

8 mm

2 mm

0.8 mm

0.5 mm

153.5 mm

160.5 mm

Double Seal

0.2 Kg

RA16013

TFL

160 mm

186 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

165 mm

179 mm

Open

0.59 Kg

RA16013C

TFL

160 mm

186 mm

13 mm

0.8 mm

165 mm

179 mm

Open

0.59 Kg

RA16013CUU

TFL

160 mm

186 mm

13 mm

0.5 mm

165 mm

179 mm

Double Seal

0.59 Kg

RA16013UU

TFL

160 mm

186 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

165 mm

179 mm

Double Seal

0.59 Kg

RA17013

TFL

170 mm

196 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

175 mm

189 mm

Open

0.64 Kg

RA17013C

TFL

170 mm

196 mm

13 mm

0.8 mm

175 mm

189 mm

Open

0.64 Kg

RA17013CUU

TFL

170 mm

196 mm

13 mm

0.5 mm

175 mm

189 mm

Double Seal

0.64 Kg

RA17013UU

TFL

170 mm

196 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

175 mm

189 mm

Double Seal

0.64 Kg

RA18013

TFL

180 mm

206 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

185 mm

199 mm

Open

0.68 Kg

RA18013C

TFL

180 mm

206 mm

13 mm

0.8 mm

185 mm

199 mm

Open

0.68 Kg

RA18013CUU

TFL

180 mm

206 mm

13 mm

0.5 mm

185 mm

199 mm

Double Seal

0.68 Kg

RA18013UU

TFL

180 mm

206 mm

13 mm

2.5 mm

1.6 mm

0.8 mm

185 mm

199 mm

Double Seal

0.68 Kg

The Unique Ultra-Thin Design and Weight Reduction

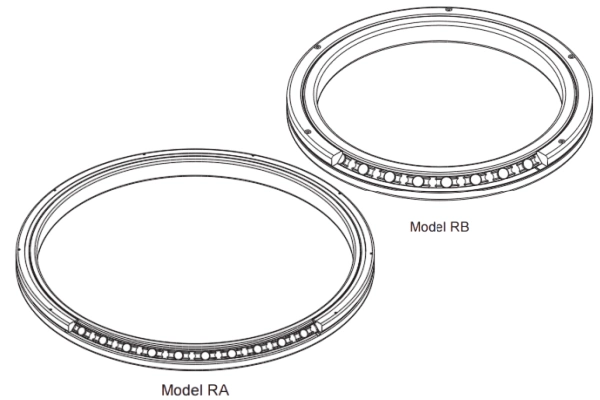

While all crossed roller bearings share a common design principle, the RA type stands out due to its ultra-thin profile. Compared to types like the RB crossed roller bearings or RU crossed roller bearings, the RA series offers a significantly reduced cross-section. This is achieved by separating the outer ring into two halves, which allows for a much thinner overall profile. This makes the RA type uniquely suited for applications where minimal weight and a compact footprint are non-negotiable.

For instance, in a robotic arm joint, the RA bearing’s slim design allows for a more streamlined and lightweight robotic hand, increasing its efficiency and range of motion. Other types, while excellent for their specific purposes, may not offer this level of space-saving advantage.

Key Features and Applications of RA Crossed Roller Bearings

The defining feature of RA crossed roller bearings is their ultra-thin wall construction. This not only saves space but also reduces the overall weight of the mechanism. The separable outer ring allows for easier installation and fine-tuning in certain applications. This design is particularly crucial for robot bearings and the rotating joints of robotic hands. In these applications, the bearing must be light enough not to add significant mass to the end effector, which would reduce the robot’s payload capacity.

The high rigidity and precision of RA bearings also make them suitable for other demanding applications, such as in rotary table bearings and certain aerospace bearings where high accuracy and low weight are critical.

The Advantage of Ultra-Thin Design in High Precision Applications

In the world of high precision bearings, the physical dimensions of the components are as important as their performance. The ultra-thin design of RA crossed roller bearings allows engineers to create more compact and lightweight machines without sacrificing precision or rigidity.

The integrated inner ring and split outer ring design ensure excellent rotational accuracy and minimal runout. This makes them a superior choice for indexing heads, medical equipment, and other devices where accuracy is paramount. Their ability to handle both radial and axial loads from a single component simplifies the design process and reduces the need for multiple bearings, further saving space and reducing complexity.

FREQUENTLY ASKED QUESTIONS

What is the difference between RA Crossed Roller Bearings and RB Crossed Roller Bearings?

The main difference lies in their ring structure and thickness. RA crossed roller bearings have an ultra-thin design with a separable outer ring and an integrated inner ring. This makes them significantly more compact and lightweight, ideal for applications where space and weight are at a premium, such as in robotic joints. In contrast, RB crossed roller bearings are the basic type with a separable outer ring but a thicker profile. While they offer excellent rigidity and are great for rotary table bearings and other machine tools, they don't provide the same level of weight and space savings as the RA type.

What specific applications are RA Crossed Roller Bearings best suited for?

Due to their ultra-thin wall design and high precision, RA crossed roller bearings are particularly well-suited for applications that require a lightweight, compact, and highly rigid bearing. Their primary use is as robot bearings and in the rotating joints of robotic arms. They are also excellent for aerospace bearings where every gram counts, as well as in semiconductor manufacturing equipment and certain high precision bearings applications in medical devices and measuring instruments.

How do RA Crossed Roller Bearings handle complex loads?

The unique design of RA crossed roller bearings allows them to handle complex loads, including simultaneous radial, axial, and moment loads. The arrangement of cylindrical rollers at a 90-degree angle to each other effectively distributes these forces. This single bearing can replace a pair of traditional angular contact ball bearings, simplifying the overall design and providing a much stiffer and more precise solution. This capability is a key reason they are the go-to choice for demanding crossed roller bearing applications.

Can RA Crossed Roller Bearings be used in high-speed applications?

While RA crossed roller bearings are primarily known for their high rigidity and precision in lower-speed, high-load applications, they can still perform well at moderate speeds. Their design is focused on stiffness and accuracy rather than high-speed operation. However, with proper lubrication and thermal management, they can be utilized in applications requiring higher rotational speeds while maintaining their high precision characteristics. For extremely high-speed applications, other bearing types may be more suitable. It is always important to consult the product specifications and application requirements to ensure the correct bearing selection.