Home / Product / Electrically Insulated Bearings / Electrically Insulated Deep Groove Ball Bearings / NTN MEGAOHM Series Insulated Deep Groove Ball Bearings

NTN MEGAOHM Series Insulated Deep Groove Ball Bearings

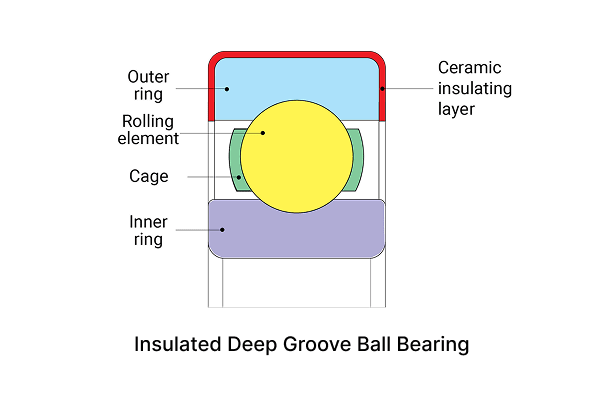

We offer high-performance solutions that can replace NTN MEGAOHM series electrically insulated deep groove ball bearings, suitable for motors, generators, and various industrial equipment equipped with frequency converters. These bearings are treated with ceramic insulation coatings on the inner or outer rings, effectively preventing current from passing through the bearings and avoiding electrical erosion damage, ensuring the long-term stable operation of the equipment.

Loading...

Total 52 Results

Model

Insulating Coating Types

Coating Suffix

Bore Diameter

Outside Diameter

Width

Basic Dynamic Load Rating

Basic Static Load Rating

Breakdown Voltage (DC)

Electrical Resistance

Cage Material

7MC3-6310C3

Outer ring ceramic coated

7MC3

50 mm

110 mm

27 mm

65.0 kN

38.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6310L1BC3

Outer ring ceramic coated

7MC3

50 mm

110 mm

27 mm

65.0 kN

38.0 kN

>3000 V

>2000 MΩ

Brass cage

2TS2-7MC2-6311M8#01

Outer ring ceramic coated

7MC2

55 mm

120 mm

29 mm

83.0 kN

47.5 kN

>3000 V

>2000 MΩ

Sheet metal

2TS2-7MC2-6311M8C4

Outer ring ceramic coated

7MC2

55 mm

120 mm

29 mm

83.0 kN

47.5 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6311C3

Outer ring ceramic coated

7MC3

55 mm

120 mm

29 mm

83.0 kN

47.5 kN

>3000 V

>2000 MΩ

Sheet metal

2TS2-7MC2-6312M8C4

Outer ring ceramic coated

7MC2

60 mm

130 mm

31 mm

85.2 kN

52.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6312C3

Outer ring ceramic coated

7MC3

60 mm

130 mm

31 mm

85.2 kN

52.0 kN

>3000 V

>2000 MΩ

Sheet metal

2TS2-7MC2-6312M8#01

Outer ring ceramic coated

7MC2

60 mm

130 mm

31 mm

85.2 kN

52.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6312L1BC3

Outer ring ceramic coated

7MC3

60 mm

130 mm

31 mm

85.2 kN

52.0 kN

>3000 V

>2000 MΩ

Brass cage

7MC3-6313C3

Outer ring ceramic coated

7MC3

65 mm

140 mm

33 mm

97.5 kN

60.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6313L1BC3

Outer ring ceramic coated

7MC3

65 mm

140 mm

33 mm

97.5 kN

60.0 kN

>3000 V

>2000 MΩ

Brass cage

7MC3-6214C3

Outer ring ceramic coated

7MC3

70 mm

125 mm

24 mm

66.0 kN

44.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6314C3

Outer ring ceramic coated

7MC3

70 mm

150 mm

35 mm

66.0 kN

44.0 kN

>3000 V

>2000 MΩ

Sheet metal

7MC3-6314L1BC3

Outer ring ceramic coated

7MC3

70 mm

150 mm

35 mm

66.0 kN

44.0 kN

>3000 V

>2000 MΩ

Brass cage

Engineered for High-Impedance and Uncompromised Strength

The “MEGAOHM” name signifies a promise of high electrical resistance, and our electrically insulated ball bearings are engineered to meet that promise. Our proprietary ceramic coating process consistently delivers an impedance level that effectively neutralizes stray currents, with breakdown voltage ratings designed to handle the spikes generated by even the most aggressive VFDs.

But electrical performance cannot come at the expense of mechanical integrity. The base bearing is a high-precision deep groove ball bearing, constructed from ultra-clean, hardened steel to provide the high dynamic load ratings and fatigue life your application demands. The coating and bearing function as a single, cohesive unit, ensuring that you receive robust mechanical strength and quantifiable electrical protection, a dual-performance guarantee that makes our product a technically sound and reliable alternative.

Secure Your Supply Chain with a Reliable NTN Alternative

Over-reliance on a single premium brand like NTN can introduce significant supply chain vulnerabilities, including long lead times and price volatility. Our interchangeable insulated bearings offer a strategic solution to this challenge. We provide a reliable, high-quality second source that de-risks your procurement process and enhances your operational agility. As a dedicated manufacturer of bearing solutions, we focus on maintaining robust inventory levels for common sizes and offer flexible, responsive production scheduling for custom or large-volume orders.

For procurement and MRO managers, this means greater control over your inventory, shorter lead times to get critical equipment back online, and a more stable, predictable cost structure. Partnering with us gives you NTN MEGAOHM-level performance with the supply chain resilience your business demands.

Resilience in Motion: Stability Under Thermal and Vibrational Stress

Electric motors rarely operate in a static, perfect environment. They are subject to constant vibration and thermal cycling, especially when managed by VFDs.

Our NTN MEGAOHM series insulated deep groove ball bearings are built for this reality. The advanced plasma-spray technique creates an exceptionally strong molecular bond between the ceramic coating and the steel ring, making it highly resistant to delamination or cracking caused by mechanical vibration or the differential thermal expansion between components. The pre-lubricated grease is selected for its stable viscosity across a wide temperature range, ensuring smooth operation whether the motor is starting cold or running at peak temperature. This resilience makes our bearings a dependable choice for demanding applications like industrial pumps, fans, compressors, and conveyors, where long-term stability is paramount.

FREQUENTLY ASKED QUESTIONS

How does a ceramic coated bearing compare to a full hybrid ceramic bearing?

This is an excellent question about choosing the right tool for the job. For most VFD-driven motor applications, our NTN MEGAOHM series insulated deep groove ball bearing provides the necessary electrical protection at a fraction of the cost of a hybrid bearing.

- A ceramic coated bearing (our product) uses traditional steel balls but has an insulating layer on one of the rings. Its primary purpose is to stop current passage and prevent EDM damage at a very effective cost.

- A hybrid ceramic bearing uses ceramic balls (e.g., Silicon Nitride) instead of steel balls. The ceramic balls are themselves insulators, so they also prevent current passage. However, hybrid bearings are significantly more expensive and are typically specified for very high-speed applications where their lower mass and higher rigidity are also beneficial.

Will the insulating coating alter the standard shaft or housing fits?

No, it will not. The thickness of our plasma-sprayed ceramic coating is controlled to be just a few hundred micrometers thick. This thickness is accounted for in the manufacturing process.

The final critical dimensions of the bearing—the outer diameter (D) and bore diameter (d)—are ground to standard ISO tolerances. This means you can use the same standard housing fits (e.g., H7) and shaft fits (e.g., k6) recommended for conventional bearings. There is no need to alter your machining or mounting practices when switching to our interchangeable insulated bearings.

What is the typical lead time for your interchangeable NTN alternative bearings?

Most orders will be shipped within 10 days or less. One of our key advantages is agility. We maintain a robust inventory of common sizes of insulated bearings that are direct replacements for popular NTN series. For these in-stock items, lead times are often significantly shorter than you might experience waiting for factory orders from major OEMs.

For larger quantities or less common sizes, we operate with a lean and efficient production schedule. Please provide us with the specific NTN part number and required quantity, and our team will provide you with a firm and competitive lead time, often helping you get your equipment back online faster.

Do your bearings meet international quality standards?

Yes, we are an ISO-certified bearing manufacturer, and all our bearings strictly comply with international quality standards.