Home / Product / Electrically Insulated Bearings / Electrically Insulated Deep Groove Ball Bearings / NSK Ceramic Coated Insulated Deep Groove Ball Bearings

NSK Ceramic Coated Insulated Deep Groove Ball Bearings

NSK Ceramic Coated Insulated Deep Groove Ball Bearings employ high-quality alumina ceramic coating technology, effectively preventing induced currents from passing through the bearings and avoiding electrical erosion damage. These bearings are particularly suitable for high-voltage applications in variable frequency motors, wind turbine generators, and power systems.

Loading...

Total 22 Results

Model

Insulating Coating Types

Bore Diameter

Outside Diameter

Width

Basic Dynamic Load Rating

Basic Static Load Rating

Breakdown Voltage (DC)

Electrical Resistance

Cage Material

6312HDY2C3

Outer ring ceramic coated

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6313HDY2C3

Outer ring ceramic coated

65.0 mm

140.0 mm

33.0 mm

97.5 kN

60.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6314HDY2C3

Outer ring ceramic coated

70.0 mm

150.0 mm

35.0 mm

104.0 kN

68.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6315HDY2C3

Outer ring ceramic coated

75.0 mm

160.0 mm

37.0 mm

119.0 kN

76.5 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6215HDY2C3

Outer ring ceramic coated

75.0 mm

130.0 mm

25.0 mm

68.9 kN

49.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6216HDY2C3

Outer ring ceramic coated

80.0 mm

140.0 mm

26.0 mm

72.8 kN

55.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6316HDY2C3

Outer ring ceramic coated

80.0 mm

170.0 mm

39.0 mm

130.0 kN

86.5 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6217HDY2C3

Outer ring ceramic coated

85.0 mm

150.0 mm

28.0 mm

87.1 kN

64.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6317HDY2C3

Outer ring ceramic coated

85.0 mm

180.0 mm

41.0 mm

140.0 kN

96.5 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6318HDY2C3

Outer ring ceramic coated

90.0 mm

190.0 mm

43.0 mm

151.0 kN

108.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6218HDY2C3

Outer ring ceramic coated

90.0 mm

160.0 mm

30.0 mm

101.0 kN

73.5 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6319HDY2C3

Outer ring ceramic coated

95.0 mm

200.0 mm

45.0 mm

159.0 kN

118.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

6319HDY2MC3

Outer ring ceramic coated

95.0 mm

200.0 mm

45.0 mm

159.0 kN

118.0 kN

Breakdown Voltage 1000v

50~200 MΩ

Brass cage

6219HDY2C3

Outer ring ceramic coated

95.0 mm

170.0 mm

32.0 mm

114.0 kN

81.5 kN

Breakdown Voltage 1000v

50~200 MΩ

Sheet metal

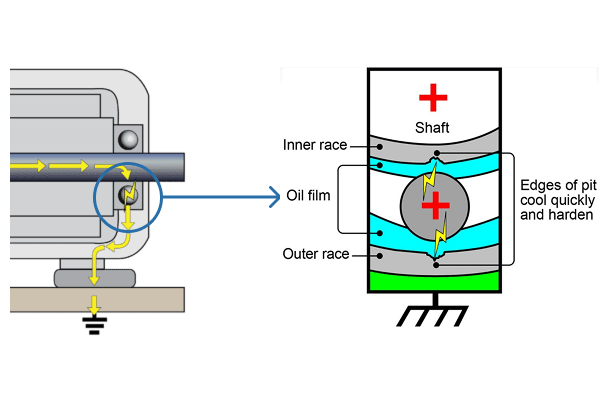

Protect Your Assets from Destructive VFD-Induced Currents

Modern Variable Frequency Drives (VFDs) are essential for energy efficiency, but they introduce a hidden threat: high-frequency stray currents. These currents seek the easiest path to ground, which is often directly through your motor’s bearings.

Our ceramic coated bearings, engineered as a direct replacement for the NSK ceramic coated series, provide the ultimate defense. The plasma-sprayed ceramic layer on the outer ring acts as a powerful electrical shield, breaking the circuit and preventing current from passing. This stops the devastating electrical erosion that pits raceways, degrades lubrication, and leads to costly, unplanned downtime. By choosing our solution, you are not just buying a component; you are implementing a proactive asset protection strategy that lowers your total cost of ownership and safeguards your production schedule from unexpected interruptions.

Interchangeable NSK Insulated Deep Groove Ball Bearing

Confidence in a replacement part begins with a perfect fit. Our insulated deep groove ball bearings are meticulously manufactured to be 100% dimensionally interchangeable with their NSK counterparts. Whether you are replacing a standard NSK bearing with a specific insulating suffix (like HDY2), our products are guaranteed to match all critical dimensions—bore, outer diameter, and width—according to international ISO standards.

This ensures a seamless, “drop-in” installation process without any need for modifications to your equipment. For maintenance teams and plant managers, this means faster repairs, reduced labor costs, and the assurance that your machinery will be back online quickly with its electrical integrity fully restored. We make sourcing a reliable, interchangeable NSK insulated ball bearing simple and risk-free.

The Intelligent Alternative for Cost-Effective Operations

In a competitive global market, smart sourcing is key to profitability. Our insulated bearings are positioned as the intelligent alternative for businesses seeking the performance of NSK ceramic coated insulated deep groove ball bearings without the associated high costs.

We deliver this exceptional value by focusing on manufacturing efficiency and supply chain optimization, allowing us to pass significant savings on to you. This enables you to protect your critical motors and generators from electrical damage while simultaneously improving your maintenance budget and product cost structure. Choosing our solution is a strategic business decision that empowers you to enhance equipment reliability and longevity without compromising your financial goals. It’s not about finding a cheaper part; it’s about finding a smarter, more valuable solution.

FREQUENTLY ASKED QUESTIONS

What is the typical breakdown voltage of your NSK ceramic coated insulated deep groove ball bearings?

Our standard aluminum oxide coating is specified to withstand a minimum of 1000V DC. This provides a substantial safety margin for the vast majority of industrial VFD applications, ensuring reliable, long-term protection against even significant stray voltage events. If your application has extreme voltage requirements, consult with our seals team for specialized solutions.

Why is the NSK ceramic coating typically on the outer ring? Can you coat the inner ring?

This is a great technical question. The outer ring is the standard and most effective location for the insulating coating because it's typically stationary in the housing. This simplifies installation and ensures the electrical barrier is complete.

Coating the inner ring is also possible (we can offer this for special projects), but it's less common. An inner ring coating is often used in applications where the outer ring rotates or where it's a more practical fit for the design. For over 95% of applications, an outer ring coating provides the necessary protection and is the most cost-effective solution.

Can I order a sample to evaluate an existing NSK bearing?

Sure. We make the evaluation process straightforward. Simply contact our sales team or use the quote request form on our website. Provide the full NSK part number you are currently using and state that you would like a sample for evaluation. Our team will promptly provide you with a quote for a single unit or a small test quantity. We understand the importance of validation, and we support our B2B clients by making it easy to test our high-quality, interchangeable bearings in their real-world applications. We're confident that once you test our product, you will recognize its outstanding value.

What payment methods do you offer?

We support multiple payment methods, including Letter of Credit (L/C), bank transfer (T/T), and PayPal, providing convenient options for customers worldwide.