Home / Product / Electrically Insulated Bearings / Electrically Insulated Deep Groove Ball Bearings / NKE Electrically Insulated Deep Groove Ball Bearings

NKE Electrically Insulated Deep Groove Ball Bearings

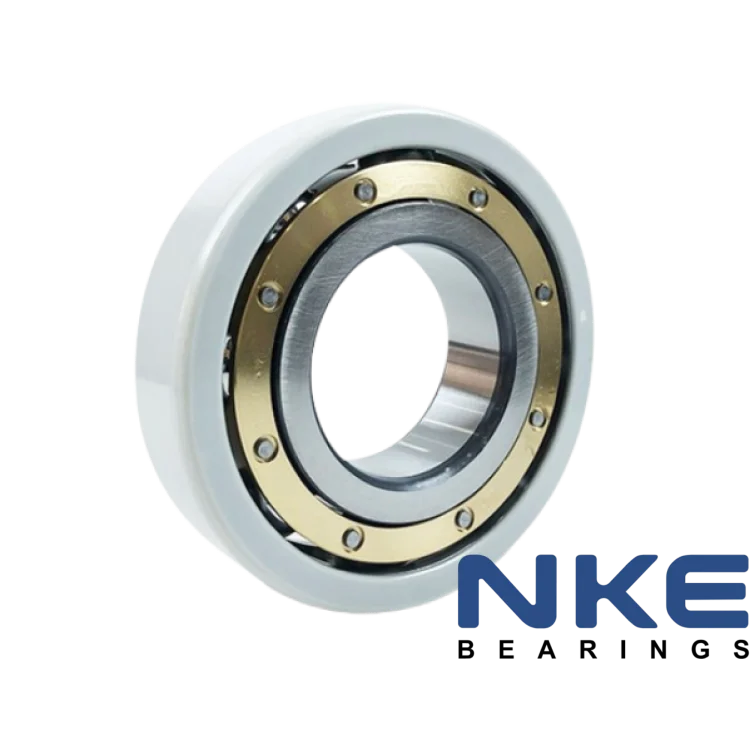

NKE Electrically Insulated Deep Groove Ball Bearings are high-performance bearing solutions specifically designed for applications such as variable frequency drive systems, motors, and generators. These bearings feature ceramic insulation coatings on either the inner or outer ring, effectively preventing current from passing through the rolling elements. This helps to prevent electrical erosion, extend the bearing’s lifespan, and ensure the long-term stable operation of the equipment.

Loading...

Total 57 Results

Model

Insulating Coating Types

Bore Diameter

Outside Diameter

Width

Basic Dynamic Load Rating

Basic Static Load Rating

Breakdown Voltage (DC)

Electrical Resistance

Cage Material

6310-M-C3-SQ77

Insulation coating on outer ring

50.0 mm

110.0 mm

27.0 mm

65.0 kN

38.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6212-M-C3-SQ77

Insulation coating on outer ring

60.0 mm

110.0 mm

22.0 mm

57.0 kN

36.5 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6212-M-C4-SQ77

Insulation coating on outer ring

60.0 mm

110.0 mm

22.0 mm

57.0 kN

36.5 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6312-M-C3-SQ77

Insulation coating on outer ring

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6312-M-C4-SQ77

Insulation coating on outer ring

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6213-M-C3-SQ77

Insulation coating on outer ring

65.0 mm

120.0 mm

23.0 mm

63.0 kN

41.5 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6213-M-C4-SQ77

Insulation coating on outer ring

65.0 mm

120.0 mm

23.0 mm

63.0 kN

41.5 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6313-M-C3-SQ77

Insulation coating on outer ring

65.0 mm

140.0 mm

33.0 mm

97.5 kN

60.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6313-M-C4-SQ77

Insulation coating on outer ring

65.0 mm

140.0 mm

33.0 mm

97.5 kN

60.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6214-M-C3-SQ77

Insulation coating on outer ring

70.0 mm

125.0 mm

24.0 mm

66.0 kN

44.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6214-M-C4-SQ77

Insulation coating on outer ring

70.0 mm

125.0 mm

24.0 mm

66.0 kN

44.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6314-M-C3-SQ77

Insulation coating on outer ring

70.0 mm

150.0 mm

35.0 mm

104.0 kN

68.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6314-M-C4-SQ77

Insulation coating on outer ring

70.0 mm

150.0 mm

35.0 mm

104.0 kN

68.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

6215-M-C3-SQ77

Insulation coating on outer ring

75.0 mm

130.0 mm

25.0 mm

68.9 kN

49.0 kN

1000 ~3000 V

50~200 MΩ

Brass cage

Superior Electrical Insulation to Prevent Bearing Failure

Our electrically insulated deep groove ball bearings are engineered as a premium alternative to NKE’s insulated series, designed to solve one of the most critical challenges in modern electric motors and generators: premature bearing failure due to electrical discharge. The core of our technology is a robust, plasma-sprayed aluminum oxide coating on the bearing’s outer ring. This ceramic layer possesses extremely high dielectric strength, effectively creating an impenetrable barrier that prevents stray electrical currents from passing through the bearing.

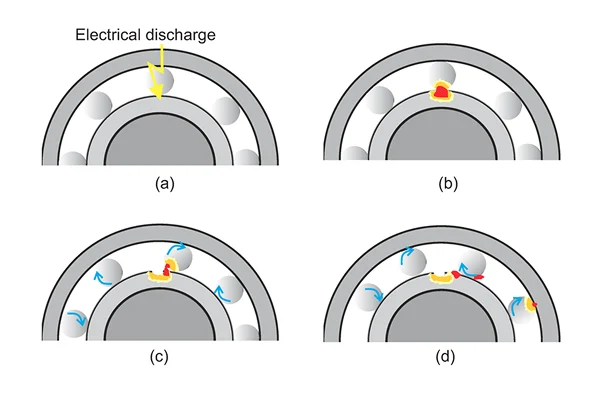

By stopping this current, we eliminate the risk of electrical discharge machining (EDM), a phenomenon where sparks create microscopic pits and craters on the raceways, degrade the lubricant, and lead to rapid wear, increased noise, and catastrophic failure. For any business operating VFD-driven motors or large-scale generators, investing in our insulated bearings is a direct investment in operational uptime and significantly reduced maintenance costs.

Seamless Interchangeability with NKE Bearings

We understand that for maintenance and engineering teams, a replacement part must be a perfect fit. Our electrically insulated ball bearings are manufactured with precision to be fully interchangeable with NKE’s standard insulated bearing series, such as their SQ77 and SQ77E lines.

This means our bearings adhere to the exact same ISO-standard dimensions—including bore diameter, outer diameter, and width—as their NKE counterparts. No modifications to your housing or shaft are required. This “drop-in replacement” capability simplifies the procurement process and makes maintenance cycles faster and more efficient. You can confidently swap out a failing NKE bearing with our solution, knowing it will fit perfectly and restore your equipment’s performance and protection against electrical damage. This commitment to dimensional accuracy ensures a smooth transition and immediate reliability for your critical machinery.

Cost-Effective Alternative to Premium Brands

Our electrically insulated deep groove ball bearings serve as a highly cost-effective alternative to NKE. We achieve this significant cost advantage through lean manufacturing processes and an optimized supply chain, not by compromising on material quality or performance standards.

For procurement managers, this translates into a direct reduction in your bill of materials (BOM) and maintenance budget. For engineers, it means you no longer have to choose between protecting your equipment and meeting your budget. You can specify a high-performance insulated bearing that provides identical protection and reliability, thereby enhancing your product’s value while improving your company’s bottom line. Choosing our interchangeable insulated ball bearings is a smart, strategic decision for any cost-conscious business.

FREQUENTLY ASKED QUESTIONS

How can I be sure your bearing is a suitable replacement for my specific NKE part number?

Finding the right replacement is simple. Bearing part numbers are highly standardized. You can provide us with the full NKE part number, for example, "6220-C3-J20AA-SQ77E". Our technical team will cross-reference it to our equivalent part. The base designation ("6220"), clearance ("C3"), and functional requirements remain the same. Our part number will have a different suffix to denote our specific insulating coating, but it will be guaranteed to be dimensionally identical and meet or exceed the electrical and mechanical performance specifications of the original. We make the process seamless to ensure you get the right part, right away.

Is your insulating coating durable enough for press-fitting during installation?

Absolutely yes. We use an advanced plasma spray technique that creates a very hard and dense ceramic layer with an extremely strong bond to the bearing's steel ring. This coating is designed to withstand the typical pressures and forces associated with standard bearing installation methods, including press-fitting and induction heating. You can follow standard mounting procedures without fear of damaging the insulating layer. Its durability is a core part of its design, ensuring the protection lasts for the entire service life of the bearing.

In which applications is using an electrically insulated bearing most critical?

Electrically insulated bearings are most critical in applications where stray currents are common. The primary culprits are AC and DC motors controlled by Variable Frequency Drives (VFDs), as the high-frequency switching in VFDs can induce currents that seek a path to ground through the motor's bearings. Other key applications include large industrial generators, wind turbine generators, and electric traction motors used in trains and public transport. In essence, if you are experiencing repeated, unexplained bearing failures in any electric motor-driven system, stray currents are a likely cause, and our insulated bearings are the definitive solution.

Do you offer samples? What is the Minimum Order Quantity (MOQ)?

Sample availability and Minimum Order Quantity (MOQ) can vary by product model. Please check the specific product page or contact our sales team for details on the bearing you need.