NTN MEGAOHM Series Insulated Single Row Cylindrical Roller Bearings

Defending Against Electrical Pitting

Electrical pitting is a common issue in bearings used in electrical systems such as motors and generators. When stray current flows through a bearing, it creates microscopic arcs that damage the raceway and rolling elements. These sparks form tiny craters or flaking on the surface, which deteriorates the structural integrity of the bearing. Over time, this leads to increased vibration, noise, and ultimately, premature failure of the bearing.

The NTN MEGAOHM Series Insulated Single Row Cylindrical Roller Bearings are specifically engineered to address this issue. By incorporating an insulating layer—made of either ceramic or resin—on the outer ring, the bearing disrupts the electrical path and effectively eliminates current flow through the rolling elements. This design not only prevents spark erosion but also reduces the risk of system downtime and equipment damage caused by unexpected bearing failure.

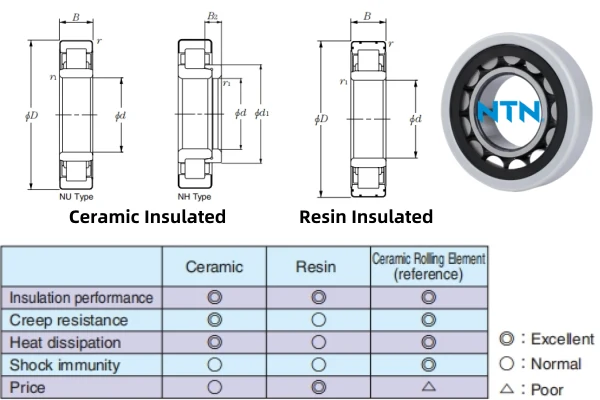

Ceramic vs Resin Insulation

The NTN MEGAOHM Series offers flexibility through its two insulation types: ceramic-coated and resin-coated. These options are designed to meet different industrial needs based on voltage level, temperature, environmental exposure, and cost considerations.

Ceramic insulation is ideal for high-voltage applications and extreme environments. It offers excellent electrical resistance and is highly stable at elevated temperatures. Ceramic coatings are also resistant to chemical corrosion and mechanical wear, making them well-suited for harsh environments such as railway traction motors and wind power systems.

On the other hand, resin insulation provides a cost-effective solution with excellent insulating performance for standard industrial applications. It is lightweight, easier to apply during production, and can still maintain insulation resistance over 100 MΩ at 500 VDC. Resin-insulated bearings are suitable for general-purpose electric motors where conditions are stable but electrical isolation is still essential.

Global Applications and Standard Compatibility

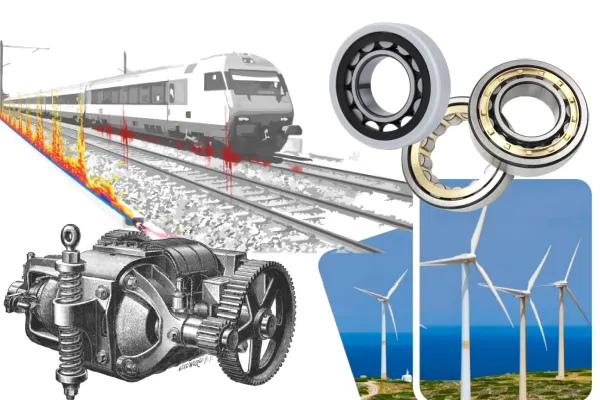

- Traction motors in railway systems, where reliability and insulation under vibration are critical

- Wind turbines, which operate in fluctuating environmental and electrical conditions

- Industrial electric motors used in pumps, compressors, and HVAC systems

FREQUENTLY ASKED QUESTIONS