Home / Product / Ball Bearings / Angular Contact Ball Bearings / Super Precision Angular Contact Ball Bearings

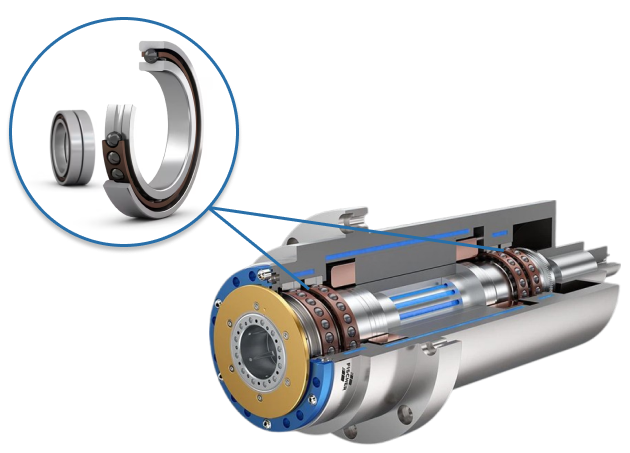

Super Precision Angular Contact Ball Bearings

Super precision angular contact ball bearings are engineered for high-speed, high-accuracy applications such as machine tools, aerospace systems, and robotics.

Loading...

Total 8286 Results

Part Number

Interchangeable

Bore Dia

Outer Dia

Width

Contact Angle

System of Measurement

Ball Material

Dynamic Radial Load

Static Radial Load

Weight

Price($)

707 CD/P4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Chrome Steel

565 lbf

220 lbf

0.008 kg

93.366

707 CD/P4ADBA

SKF

7 mm

19 mm

12 mm

15°

Metric

Chrome Steel

907 lbf

441 lbf

0.016 kg

707 CDGA/P4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Chrome Steel

565 lbf

220 lbf

0.008 kg

707 CE/HCP4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Ceramic

439 lbf

144 lbf

0.006 kg

93.258

707 CE/HCP4ADGA

SKF

7 mm

19 mm

12 mm

15°

Metric

Ceramic

702 lbf

286 lbf

0.012 kg

707 CE/HCP4AH

SKF

7 mm

19 mm

6 mm

15°

Metric

Ceramic

439 lbf

144 lbf

0.006 kg

707 CE/HCPA9ADGA

SKF

7 mm

19 mm

12 mm

15°

Metric

Ceramic

702 lbf

286 lbf

0.012 kg

707 CE/P4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Chrome Steel

439 lbf

144 lbf

0.007 kg

92.826

707 CE/P4ADBA

SKF

7 mm

19 mm

12 mm

15°

Metric

Chrome Steel

702 lbf

286 lbf

0.014 kg

707 CE/P4ADBC

SKF

7 mm

19 mm

12 mm

15°

Metric

Chrome Steel

702 lbf

286 lbf

0.014 kg

707 CE/P4ADT

SKF

7 mm

19 mm

12 mm

15°

Metric

Chrome Steel

702 lbf

286 lbf

0.014 kg

707 CE/PA9ADGA

SKF

7 mm

19 mm

12 mm

15°

Metric

Chrome Steel

702 lbf

286 lbf

0.014 kg

707 CEGA/HCP4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Ceramic

439 lbf

144 lbf

0.006 kg

707 CEGA/P4A

SKF

7 mm

19 mm

6 mm

15°

Metric

Chrome Steel

439 lbf

144 lbf

0.007 kg

Exceptional Running Accuracy and Precision

Super precision angular contact ball bearings meet extreme tolerances (P4, P2, ABEC 7/9) for outstanding running accuracy, minimizing runout.

Buyers needing ultimate positioning accuracy and smooth operation in critical applications like machine tool spindles or measuring instruments rely on this precision bearing performance.

It ensures better workpiece quality and process reliability, and the precise performance is necessary for high-end machinery. Choose precision for superior results.

Designed for High Combined Loads

The specific contact angle in these angular contact bearings allows them to accommodate both radial and axial loads at the same time, primarily in one direction.

This makes super precision angular contact ball bearings the ideal choice for applications where axial loads are significant alongside radial forces.

Choosing the correct contact angle (e.g., 15°, 25°) is crucial for optimising load capacity and bearing life, ensuring your equipment performs reliably under its specific operating conditions.

Superior High-Speed Performance

Engineered with optimised internal geometry, quality materials, and superior manufacturing, these high precision ball bearings excel at high rotational speeds. Reduced friction and heat allow machinery to operate faster and more efficiently.

For high-RPM applications like high-speed spindle or turbo machine, invest in super precision angular contact ball bearings for the necessary capability and durability. Boost your productivity with bearings designed for speed and endurance.

FREQUENTLY ASKED QUESTIONS

What specifically qualifies a bearing as "Super Precision"?

It refers to meeting stringent international standards (like ISO Class 4/2, ABEC 7/9) for dimensional and running accuracy, significantly tighter than standard bearings. This ensures higher performance capabilities for demanding applications.

What does the contact angle (e.g., 15°, 25°) tell me when purchasing?

The contact angle indicates the bearing's relative capacity for axial vs. radial loads. A larger angle (like 25°) offers higher axial load capacity but lower speed limits compared to a smaller angle (like 15°). Choose based on your primary load type.

What lubrication is recommended for these high precision bearings?

High-speed applications often use specialized oils delivered via oil-air or oil-mist systems. For lower speeds or simpler setups, specific high-quality greases designed for precision bearings are suitable. Consult product details or contact us for recommendations.

How long will it take to ship after the payment?

We have sufficient inventory. Most orders will be shipped within 10 days or less. After the order is dispatched, you can track the logistics information at any time until the goods are signed for.