Enhancing Continuous Caster Reliability: High-Performance Bearing Solutions

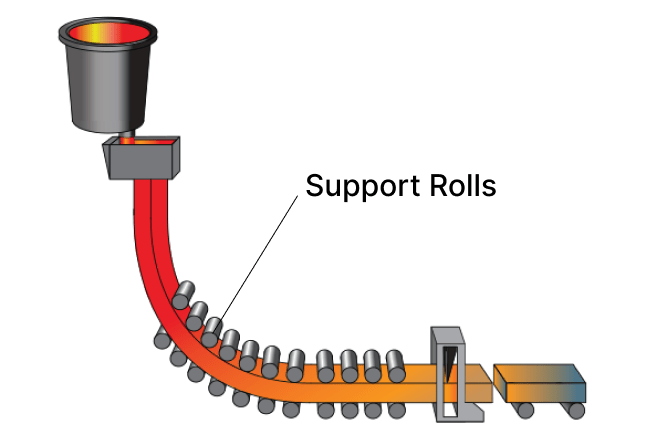

A Continuous Caster is a cornerstone of modern steel production. Its core function is to continuously solidify molten steel from the ladle into semi-finished shapes like slabs, billets, or blooms. As the pivotal link between steelmaking and rolling, the continuous caster’s performance directly dictates the efficiency, cost, and quality of the entire production line.

The operating environment of a continuous caster is extreme. Bearings face a severe combination of high radiant heat, heavy loads, very low speeds, constant exposure to water and steam, and contamination from iron oxide scale. Any unplanned downtime caused by bearing failure results in massive production losses and significant safety risks.

Drawing on decades of expertise in the steel industry, TFL Bearing offers a complete portfolio of high-performance bearing solutions specifically engineered for critical caster applications, including segment rolls, straighteners, and run-out tables. Our products are designed with specialized materials and features to withstand these extreme conditions and deliver maximum operational uptime.

By implementing TFL’s dedicated caster bearing solutions, you will achieve:

- Increased Equipment Uptime: Drastically reduce unplanned stops caused by premature bearing failure.

- Lower Maintenance Costs: Extend bearing service life, cutting down on replacement frequency and labor.

- Improved Production Quality: Ensure stable billet/slab transport and forming for a higher-quality end product.

- Enhanced Operational Safety: More reliable components mean fewer maintenance interventions in hazardous areas.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool

Electric Motors

Metallurgical Industry

Industrial Pumps

Compressors

Food & Beverage Machinery

Plup and Paper

Plastic Machinery

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Common Bearing Problems in Continuous Caster

In the extreme environment of a continuous caster, bearing failure modes are complex and often result from a combination of stressors. Identifying these patterns and their root causes is the first step toward improving equipment reliability. The table below outlines the most frequent bearing issues and their underlying technical causes.

Common Problems List

| Failure Mode | Symptoms | Primary Causes |

| Premature Spalling & Fatigue | Flaking or pitting on raceways or rollers. |

|

| Corrosion & Rust | Widespread rust or localized pitting on bearing surfaces. |

|

| Inner Ring Cracking | Axial or radial cracks, sometimes leading to complete fracture of the inner ring. |

|

| Lubricant Degradation | Grease becomes carbonized (hardened), dried out, or emulsified (milky white). |

|

Application Analysis for Continuous Caster

For the harsh and demanding environments in steel casting, we provide proven, high-performance bearing solutions for every critical position:

Application Scenario 1: Segment Supprot Rolls

- Operating Conditions: This is the heart of the caster and the most demanding area. Bearings are exposed to intense radiant heat (over 1000°C) from the hot slab and support its immense weight (heavy radial loads). Speeds are extremely low (<10 rpm), making it difficult to form a protective hydrodynamic lubricant film. Constant water spray and scale contamination are unavoidable, demanding superior sealing and corrosion resistance. Misalignment from thermal expansion and frame distortion is also a major factor.

- TFL Recommended Solution: Spherical Roller Bearings – Steel Industry Series

This solution is engineered specifically for this challenge:

- Self-Aligning Capability: The barrel-shaped rollers and sphered outer ring raceway accommodate misalignment of up to ±1.5°, preventing damaging edge stresses caused by shaft deflection.

- High Load-Carrying Capacity: The optimized internal design and double-row roller configuration easily manage the heavy radial loads from the steel slab.

- Advanced Material & Design: Made from heat-stabilized steel (S2 grade or higher) to ensure dimensional stability at operating temperatures up to 200°C, preventing inner ring cracking. An increased C4 radial internal clearance accommodates thermal expansion.

- Integrated Sealing: Available with highly effective contact seals that work with the bearing’s design to block out water and scale contamination, protecting the internal components.

Application Scenario 2: Pulling And Straightening Machine

- Operating Conditions: The straightener applies immense force to bend the solidified slab into its final flat shape. This subjects the bearings to huge, fluctuating straightening forces and heavy shock loads. High temperatures and moisture are still present.

- TFL Recommended Solution: Four-Row Tapered Roller Bearings or Spherical Roller Bearings

- Four-Row Tapered Roller Bearings: Designed for the extreme loads of rolling mills, their multi-row configuration provides exceptional radial and axial stiffness, making them ideal for handling the immense shock loads of the straightening process.

- Heavy-Duty Spherical Roller Bearings: In straighteners with lower loads or where some misalignment is expected, a robust spherical roller bearing offers a reliable and cost-effective alternative with easier installation.

Application Scenario 3: Roller Table

- Operating Conditions: This section transports the slab away from the straightener. While temperatures are lower, loads are still heavy, and the environment remains wet and contaminated with scale dust. Reliability and ease of maintenance are top priorities.

- TFL Recommended Solution: Pillow Block Units – Heavy-Duty Series

- Easy Installation: The integrated bearing and housing unit greatly simplifies mounting and alignment, reducing maintenance time.

- Superior Sealing: Equipped with multi-stage seals (e.g., triple-lip seals plus a flinger) to provide excellent protection against contaminants.

- Self-Aligning: The spherical outer surface of the bearing allows it to pivot within the housing, compensating for initial mounting inaccuracies.

- Simple Maintenance: Features a grease fitting for easy and convenient re-lubrication to extend service life.

Core Products at a Glance - Quick Reference for Caster Bearings

| Application Part | Bearing Type | Common Part Numbers (Examples) | Key Features |

| Segment Supprot Rolls | Spherical Roller Bearing | 24132 CA/C4W33 23236 MB/C4W33 | Self-aligning, C4 clearance, High-temp stabilization (S2), High radial load capacity |

| Pulling And Straightening Machine | Four-Row Tapered / Spherical Roller Bearing | 24140 CA/C4W33 | Extreme rigidity, High shock load capacity, Long service life |

| Drive Side | Cylindrical + Angular Contact Ball Bearings | NU 320 ECP + 7320 BECBM | Handles high radial load, provides precise axial location, accommodates thermal expansion |

| Roller Table | Pillow Block Units | UCP318 UCF320 UCFL316 | Easy installation, Enhanced sealing, Self-aligning, Simple re-lubrication |

Note: Final bearing selection depends on specific load, speed, and dimensional requirements. Please consult a TFL application engineer for a precise recommendation.

TFL Boosting Caster Segment Roll Reliability, Slashing Unplanned Downtime by 50%!

TFL's solution tackles frequent bearing failures in continuous casters caused by heat, heavy loads, and contamination. Our specialized bearings extend service life, reducing costly downtime and maintenance.

Your Lowest Cost-Per-Ton Starts with Unmatched Reliability

In the 24/7 operation of a continuous caster, the price of a bearing is negligible compared to the cost of lost production. Yet, the reliability of these critical components dictates the plant's overall output and profitability. Choosing TFL high-performance bearings—engineered specifically to withstand extreme heat, heavy loads, slow speeds, and constant contamination—is a strategic decision to maximize uptime. It not only prevents catastrophic failures and unplanned downtime but also ensures a consistent production flow, directly lowering your cost-per-ton.