High-Performance Bearing Solutions Engineered for the Metallurgy

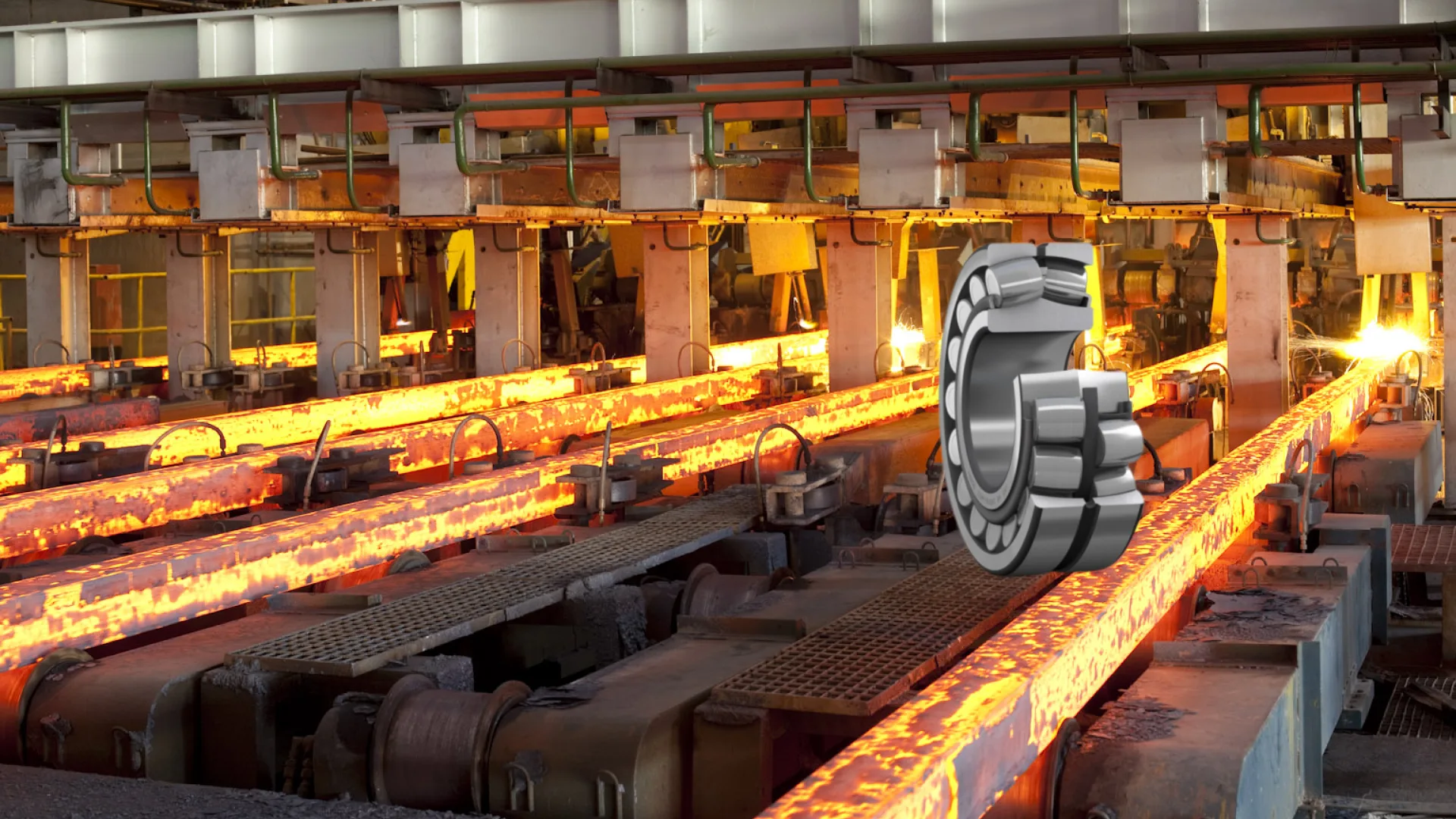

The metallurgy industry is the backbone of modern manufacturing, where continuous operation is paramount. From iron and steelmaking to rolling and finishing, equipment is constantly exposed to the ultimate tests: extreme temperatures, immense shock loads, and harsh contamination from scale, water, and dust. Any unplanned downtime of critical machinery leads to significant production losses and exorbitant maintenance costs.

TFL understands these challenges intimately. We are more than a bearing manufacturer; we are your strategic partner in overcoming severe operating conditions. Leveraging our deep expertise in material science, heat treatment, sealing technology, and precision engineering, we have developed a portfolio of bearing solutions specifically for the metallurgy sector. Our mission is to help you significantly reduce your Total Cost of Ownership (TCO) and achieve superior production efficiency by providing exceptionally reliable, long-lasting bearings and expert technical support.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Continuous Casters

Discover high-performance bearings for continuous casters. Ensure reliability, reduce downtime, and extend service life.

Metallurgical Industry

Key Technical Applications of TFL Bearings in Continuous Casters

As the heart of the steelmaking process, continuous casters operate under relentless high radiant heat, direct water spray, and scale contamination. Premature bearing failure is a primary cause of production stoppages and quality issues...

Key Technical Applications of TFL Bearings in Hot Rolling Mills

Bearings in the work and backup rolls of hot rolling mills must withstand extreme rolling pressures, shock loads, and high temperatures. TFL's four-row tapered and cylindrical roller bearings are engineered with...

Key Technical Applications of TFL Bearings in Converters

Converter trunnion bearings support the immense weight of the entire furnace and endure heavy, low-speed oscillating loads and intense heat. TFL's large-size spherical roller bearings are designed with exceptionally high radial and...

Key Technical Applications of TFL Bearings in Cold Rolling & Finishing Lines

Unlike hot rolling, cold rolling and finishing lines demand the highest levels of product precision and surface quality. This requires bearings with exceptional rotational accuracy, high stiffness, and unwavering reliability...

Far More Than This

Metallurgical Industry Applications

Application List

Ironmaking & Steelmaking

- Blast Furnace Equipment

- Sinter Pallet Cars

- Ladle Turrets

- Torpedo Ladle Cars

Rolling & Finishing

- Coilers / Uncoilers

- Straighteners

- Flying Shears

- Cooling Beds

Material Handling & Auxiliary

- Overhead Cranes

- Conveyor Belts

- Fans and Pumps

- Gearboxes

TFL Boosting Caster Segment Roll Reliability, Slashing Unplanned Downtime by 50%!

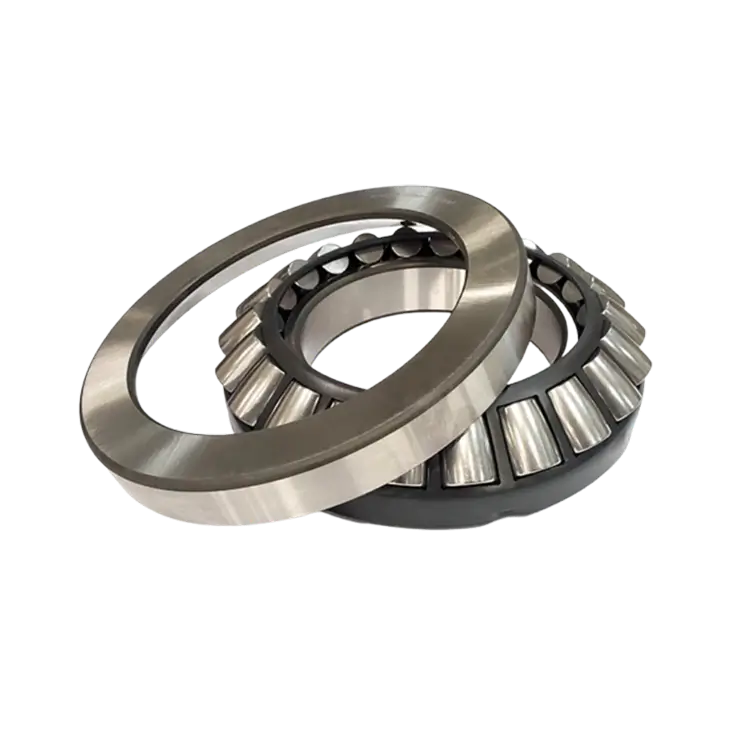

TFL's solution tackles frequent bearing failures in continuous casters caused by heat, heavy loads, and contamination. Our specialized bearings extend service life, reducing costly downtime and maintenance.

What is the key difference when selecting bearings for a continuous caster's upper segments versus its straightener section?

An excellent technical question. Bearings in the upper segments are closer to the hot slab and face greater thermal stress and direct water cooling. Selection here prioritizes high-temperature capability, robust sealing against water ingress, and designs that accommodate thermal expansion. In contrast, the straightener section bearings endure higher mechanical loads and shock. The focus there is on superior load-carrying capacity, impact toughness, and wear resistance. TFL offers distinct, optimized solutions for each of these demanding zones.

What specific design optimizations are in TFL's four-row tapered roller bearings for rolling mills?

Our TQO type bearings for rolling mills incorporate several key enhancements. We utilize a logarithmic roller profile to optimize stress distribution between the rollers and raceways, increasing both load capacity and service life. High-precision spacers ensure accurate preload settings and uniform load sharing across all four rows. Furthermore, we can offer designs with helical lubrication grooves on the inner ring to improve lubrication effectiveness and integrated, high-efficiency seals built to withstand the mill environment.

Upgrading to TFL high-performance bearings has a higher initial cost. Is it worth it in the long run?

Absolutely. From a Total Cost of Ownership (TCO) perspective, it is a sound financial decision. While the initial purchase price may be higher, the long-term savings from TFL bearings—achieved through extended service life, drastically reduced unplanned downtime, lower maintenance frequency, and decreased lubricant consumption—far outweigh the initial investment. One quality investment prevents multiple costly production losses and emergency repairs.

How can we effectively extend bearing lubrication life in an environment full of scale and cooling water?

The solution is a dual approach focusing on "sealing" and "lubrication." First, specifying TFL bearings with our effective contact or labyrinth seals provides the first line of defense against contaminant ingress. Second, we highly recommend using a centralized automatic lubrication system. Our technical experts can work with you to define the optimal grease type and replenishment intervals based on your specific load and environmental conditions. Regular flushing of the housing and seal inspection during maintenance windows are also crucial for ensuring long, reliable operation.

Our mill equipment is from major OEMs like SMS group or Danieli. Are TFL bearings a direct replacement for their spare parts?

Yes, they are. TFL manufactures bearings in strict accordance with ISO standards and has extensive experience providing both OEM and aftermarket solutions for major equipment brands. Our products are fully interchangeable with original parts in terms of dimensions, tolerances, and performance ratings. Simply provide the original bearing designation or equipment drawing, and our engineering team will provide a 100% compatible—and often superior—replacement solution, complete with installation support.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Lower Your Cost-Per-Ton in Extreme Heat

In the demanding world of metallurgy, the cheapest bearing often leads to the highest cost-per-ton. A bearing engineered specifically for extreme heat, heavy loads, and contamination is a strategic investment, delivering unmatched value through uninterrupted production, fewer unplanned shutdowns, and superior reliability under the most punishing conditions.