Improving Machine Tool Spindle Reliability: High-Performance Bearing Solutions

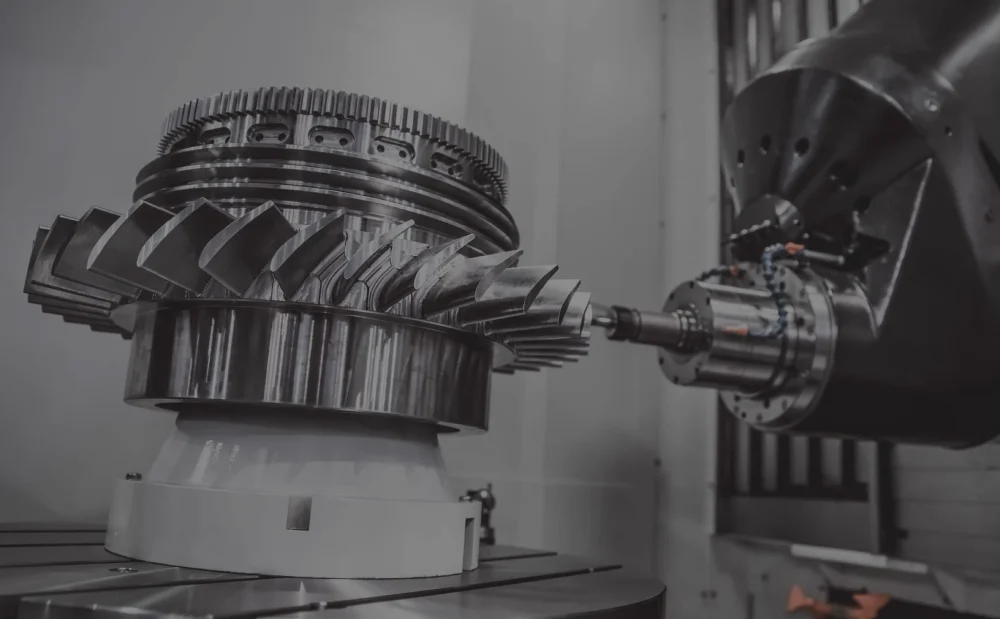

The machine tool spindle is the heart of equipment like CNC machining centers, grinders, and lathes. Its core function is to hold and rotate a tool or workpiece with exceptional precision and speed. The performance of the spindle directly determines the final machining accuracy, surface finish, and overall production efficiency. From high-speed milling to heavy-duty turning, a reliable spindle is fundamental to quality manufacturing.

A machine tool spindle operates under extreme conditions, constantly balancing three competing factors: speed, precision, and rigidity. Pushing for higher speeds to increase output generates more centrifugal force, heat, and vibration, which can compromise machining accuracy. At the same time, the spindle requires immense rigidity to withstand powerful cutting forces without deflection. This “impossible triangle” places extreme demands on the spindle’s most critical components: its bearings.

To meet this challenge, TFL provides high-performance, precision-engineered bearing solutions specifically for machine tool spindles. Our portfolio, featuring High-Precision Angular Contact Ball Bearings (including Hybrid Ceramic options) and Double-Row Cylindrical Roller Bearings, is built to master this balancing act. Through superior materials, optimized internal geometry, and P4/P2 manufacturing tolerances, we provide a solid foundation for modern spindles to achieve peak performance.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

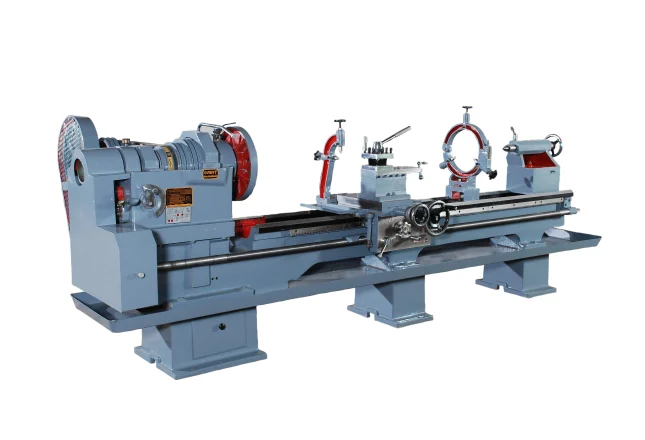

Machine Tool

Electric Motors

Metallurgical Industry

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Common Problems List for Spindle Bearings

Spindle bearing failures are often complex, resulting from multiple factors. Simply replacing a bearing doesn’t solve the root cause. A precise diagnosis is the first step toward improving the reliability of the entire spindle system. The table below outlines the most common failure modes and their underlying causes.

Common Problems List

| Failure Mode | Specific Manifestation | Primary Causes |

| Loss of Accuracy & Increased Vibration | Chatter marks on workpiece surfaces, dimensional errors, abnormal noise, or vibration during operation. | 1. Improper preload (too loose or too tight). 2. Incorrect shaft/housing fit. 3. Grease degradation or contamination. 4. Damage to the raceways from fretting or debris. |

| Excessive Temperature Rise | Spindle temperature consistently exceeds its operational limit, often triggering machine alarms. | 1. Excessive preload causing high internal friction. 2. Insufficient, incorrect, or excessive lubrication. 3. Operating speeds beyond the bearing’s limit. 4. Malfunctioning cooling system. |

| Bearing Seizure | The spindle locks up suddenly, often with a loud noise. This represents a catastrophic failure. | 1. Complete lubrication failure. 2. Intrusion of cutting fluid or metal chips into the bearing. 3. Material degradation from prolonged overheating, causing components to weld together. |

Analysis of Common Application Scenarios for Machine Tool Spindle

For the demanding and varied conditions of machine tools, we offer proven, high-performance bearing solutions for each key application.

Application Scenario 1: High-Speed Machining (HSM) Center Spindles

- Operating Condition Analysis: These spindles operate at speeds from 15,000 to 40,000 RPM or higher. The primary challenge is managing the centrifugal force and frictional heat generated at these speeds. Any change in preload due to thermal expansion can destroy the spindle’s dynamic accuracy and stability. This demands bearings with exceptional speed capability, low heat generation, and high dynamic stiffness.

- TFL Recommended Solution: Hybrid Ceramic Angular Contact Ball Bearings (ACBB)

- Higher Speed, Less Heat: Si3N4 ceramic balls are 60% less dense than steel. This dramatically reduces centrifugal force at high speeds, leading to less friction, lower heat generation, and a higher limiting speed for the spindle.

- Greater Rigidity: Ceramic has a higher modulus of elasticity, providing greater system stiffness compared to all-steel bearings. This helps resist cutting forces and maintain precision.

- Longer Life: Excellent wear resistance and anti-galling properties ensure superior performance even under poor lubrication, extending maintenance intervals.

Application Scenario 2: Heavy-Duty Lathe & Milling Machine Spindles

- Operating Condition Analysis: These spindles run at lower speeds but endure immense radial loads and shock from heavy or interrupted cuts. The main challenge is providing extreme system rigidity to minimize deflection at the tool tip, ensuring dimensional accuracy and surface quality under heavy load.

- TFL Recommended Solution: A Combined Front and Rear Bearing Arrangement

- Front (Tool Side): High-Rigidity Angular Contact Ball Bearing Set

- Arranged back-to-back (DB) or in a quad set (QBC), this configuration provides maximum radial and bi-directional axial load capacity. It creates a robust pivot point that strongly resists the tilting moments from cutting forces.

- Rear (Drive Side): Double-Row Cylindrical Roller Bearing

- This bearing offers unmatched radial rigidity and load capacity, specifically designed to handle the heavy radial forces from belts or gears. Its design allows for small axial displacement as the spindle heats up and expands, preventing thermal stress on the front bearing set and ensuring system stability.

Core Product Overview - Spindle Bearing Quick Reference Table

| Application Part | Bearing Type | Common Specific Models | Key Features |

| Front (Tool Side) | High-Precision ACBB | 7012C, 7008C | 15° contact angle for high-speed operation |

| Front (Tool Side) | Hybrid Ceramic ACBB | HCB7007-C | Ultra-high speed, low heat, high rigidity |

| Front (Heavy-Duty) | High-Rigidity ACBB | 7210AC | 25° contact angle for higher load capacity |

| Rear (Floating End) | Double-Row Cylindrical Roller Bearing | NN3020K,NN3018K | Extreme radial rigidity, allows axial movement |

TFL Boosts CNC Spindle Precision & Stability, Delivering $27,600 in Annual Savings!

This case study shows how TFL's high-precision spindle bearings solved a client's CNC machine failure and accuracy issues, significantly boosting equipment performance and market competitiveness.

Unlock Higher Precision and Profitability with Performance Spindle Bearings

For a machine tool spindle, the cheapest bearing almost always results in the highest cost-per-part. A purpose-built, high-precision bearing requires a greater initial investment, but it delivers superior ROI through unmatched machining accuracy, higher spindle speeds, reduced scrap rates, and a significantly longer, more reliable service life.