Delivering Sub-Micron Precision and Stability at Extreme Speeds

The machine tool industry is the cornerstone of modern manufacturing. It demands the highest levels of speed, precision, and rigidity. Whether it’s high-speed cutting, precision grinding, or heavy-duty milling, even the slightest deviation can lead to costly scrapped parts and production downtime. Common challenges include high spindle temperatures, inaccurate ball screw positioning, and insufficient rotary table rigidity.

TFL understands these challenges deeply. We are more than just a bearing supplier; we are your partner in achieving precision. By using advanced materials, ultra-precision manufacturing, and a deep understanding of machine tool applications, TFL provides bearing solutions that exceed expectations. We help our customers’ equipment run cooler at extreme speeds and maintain superior rigidity under heavy loads. This leads to higher machining accuracy, longer equipment life, and a lower total cost of ownership (TCO).

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool Spindle

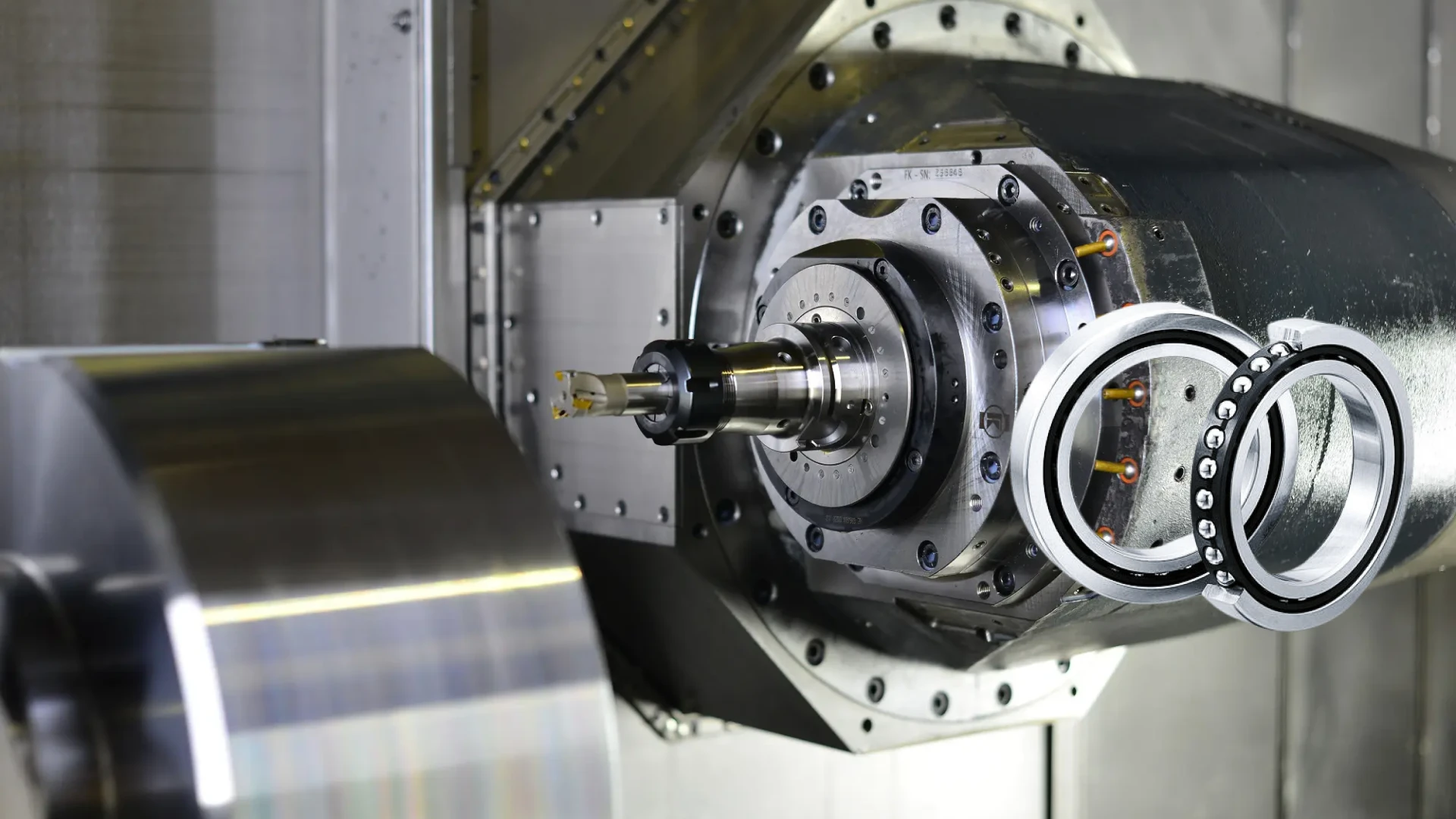

Solutions Themachine tool spindle is the heart ofequipment like CNC machining centers,grinders, and lathes. lts core function is tohold and rotate a tool or workpiece withexceptional precision and speed. Theperformance of the spindle directlydetermines the final machining accuracy,surface finish, and overall productionefficiency.

Machine Tool Bearings

Key Technical Applications of TFL Bearings in Machine Tool Spindles

The spindle is the heart of a machine tool. Its performance directly determines the final machining quality. Bearings in this application must handle combined radial and axial loads at speeds of tens of thousands of RPM...

Key Technical Applications of TFL Bearings in Ball Screw Support

Ball screws are critical for precise linear positioning. Their support bearings must provide extremely high axial rigidity to handle thrust from the drive motor and eliminate backlash, ensuring micron-level accuracy...

Key Technical Applications of TFL Bearings in Rotary Tables

Rotary tables, including 4th and 5th axes, require bearings that can manage radial, axial, and tilting moment loads simultaneously, all while maintaining high indexing accuracy. TFL's Crossed Roller Bearings offer exceptional rigidity and...

Key Technical Applications of TFL Bearings in Tool Turrets & ATCs

Fast and precise tool changes from turrets and Automatic Tool Changers (ATCs) are key to reducing non-cutting time. Bearings in these mechanisms must withstand frequent start-stop shock loads in a compact space and...

Far More Than This

Machine Tools Applications

Application List

Drive & Transmission Systems

- Gearboxes

- Spindle Motors

- Servo Motors

Auxiliary & Support Systems

- Coolant Pumps

- Chip Conveyors

- Hydraulic/Pneumatic Units

Measurement & Inspection Equipment

- Coordinate Measuring Machines (CMMs)

- On-machine Probing Systems

- Tool Presetting Instruments

Tfl Bearings Help German Customer Increase Servo Motor Efficiency Fivefold

TFL supplied a German servo motor maker with P5/ZV3 precision bearings, solving their supply issues. This enhanced motor performance and secured a long-term partnership, improving product reliability.

How to Choose the Right Angular Contact Bearings for 5-Axis CNC Machines

Choose the right angular contact bearings for 5-axis CNC machines by matching load, speed, and precision needs to boost accuracy and extend machine life.

For a high-speed machining center spindle, should I choose all-steel bearings or ceramic hybrid bearings?

Why is preload so important for TFL spindle bearings, and how should I choose the right level?

Investing in TFL high-precision bearings seems to cost more upfront. How does it lower my total cost of ownership (TCO)?

For a high-speed motorized spindle, is grease or oil-air lubrication better? What does TFL recommend?

My machine currently uses bearings from another major brand (e.g., SKF, NSK). Can I use TFL products as a direct replacement? Is the performance guaranteed?

Absolutely. All TFL products are manufactured to strict ISO/DIN standards, ensuring they are dimensionally interchangeable with major brands. In terms of performance, we are confident that our advanced designs, materials, and manufacturing processes can meet or even exceed the performance of the original parts. Simply provide our sales engineers with the original bearing part number, and we will give you the exact TFL equivalent and detailed technical data to ensure a seamless and successful upgrade.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Unlock Higher Precision and Profitability with Performance Bearings

For precision machine tools, a seemingly low-cost bearing often results in the highest cost-per-part. A purpose-built, high-precision bearing may require a higher initial investment, but it delivers superior ROI through unmatched machining accuracy, reduced scrap rates, and a significantly longer spindle life.