High-Efficiency Industrial Motor Reliability: High-Performance Bearing Solutions

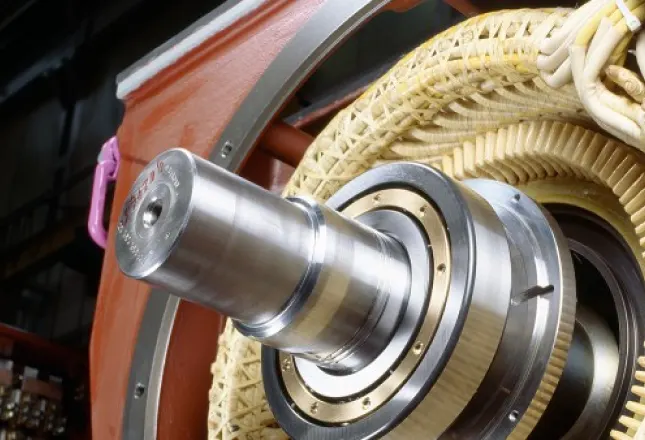

High-efficiency industrial motors, typically referring to three-phase induction motors meeting IE3 (Premium Efficiency) or higher standards, are the workhorses of modern industry. As the core units for converting electrical energy into mechanical power, they are essential for powering pumps, fans, compressors, conveyors, and automated production lines, forming the cornerstone of continuous and efficient industrial operations.

With the widespread adoption of Variable Frequency Drives (VFDs) and the relentless pursuit of energy efficiency, modern motors face a critical challenge: electrical erosion. High-frequency common-mode voltages generated by VFDs can cause damaging electrical discharges through the bearings. These micro-arcs rapidly degrade the raceway surfaces and grease, leading to premature bearing failure, unplanned downtime, and significant production and maintenance losses.

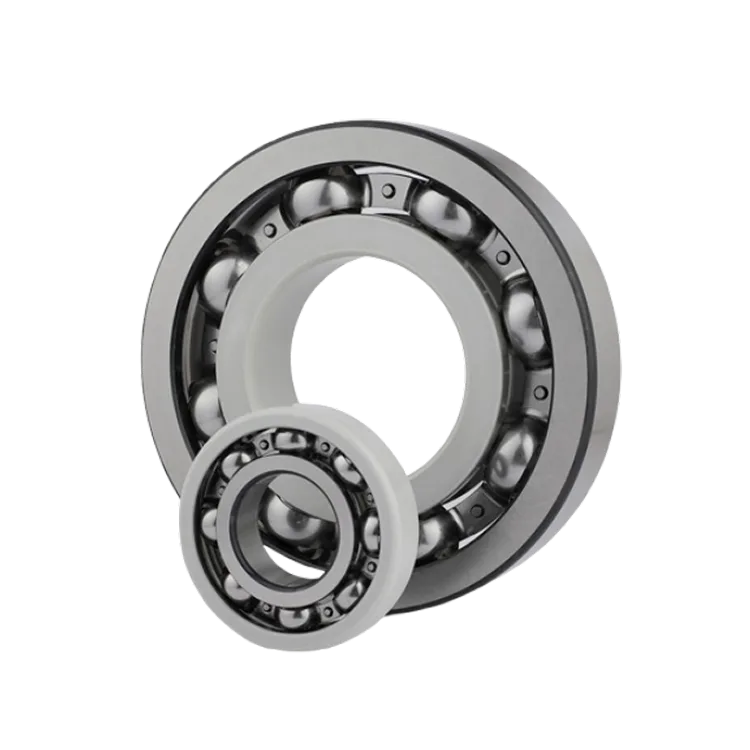

TFL directly addresses this industry-wide pain point with a dedicated range of bearing solutions engineered for high-efficiency motors, including Insulated Bearings and Hybrid Ceramic Bearings. These products are designed to fundamentally block the path of destructive electrical currents, ensuring the long-term, stable operation of motors in VFD environments.

By implementing TFL’s specialized motor bearing solutions, you will gain:

- Superior Equipment Reliability: Eliminate the risk of electrical erosion, extend bearing service life significantly, and drastically reduce failure rates.

- Lower Maintenance Costs: Extend maintenance intervals, reducing the need for replacement parts and labor.

- Maximized Productivity: Prevent costly unplanned downtime and ensure continuous production.

- Optimized Total Cost of Ownership (TCO): Achieve the lowest lifecycle cost through enhanced reliability and efficiency.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool

Electric Motors

Metallurgical Industry

Industrial Pumps

Compressors

Food & Beverage Machinery

Plup and Paper

Plastic Machinery

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Common Bearing Problems in High-Efficiency Motors

Bearing failure in industrial motors is often complex, with root causes extending beyond the bearing itself. Accurate diagnosis is the first step toward an effective solution. The table below outlines the most common bearing failure modes in high-efficiency motor applications.

Common Problems List

| Failure Mode | Symptoms | Primary Causes |

| Electrical Erosion (EDM) | “Fluting” or “washboard” patterns on raceways; micro-pitting or dull surfaces on rolling elements; blackened, degraded grease. | High-frequency shaft voltages from VFDs discharging through the bearing, creating micro-welds and material erosion. |

| Premature Grease Degradation | Hardened, discolored, or dried-out grease; abnormally high operating temperatures; increased noise and vibration. | Sustained high temperatures, grease carbonization from electrical discharge, or selection of an improper grease type. |

| Cage Failure | Fractured or deformed cage; bearing seizure or emitting loud, metallic noises. | Excessive vibration and shock, stress concentration from improper mounting, or high centrifugal forces at high speeds. |

| Premature Fatigue | Spalling or flaking on the surface of raceways or rolling elements. | Loads exceeding the bearing’s design capacity, misalignment causing stress concentration, or internal contamination. |

Application Analysis for High-Efficiency Motors

To address the demanding and varied operating conditions of industrial motors, we offer proven, high-performance bearing solutions for each critical application point:

Application Scenario 1: Drive End (DE) of VFD-Controlled Motors

- Operating Conditions: The drive end (DE) is the primary load-bearing position, subject to high radial forces. The most severe challenge is that it serves as the most common path for shaft currents to discharge to the ground, making it highly susceptible to electrical erosion.

- TFL Recommended Solution: Insulated Deep Groove Ball Bearing

This solution features a robust aluminum oxide (Al₂O₃) insulating coating applied to the bearing’s outer ring, capable of withstanding voltages up to 3000V DC. This coating creates a physical barrier that blocks the path of electrical current, completely eliminating the conditions for electrical erosion. It is the most direct and reliable solution for VFD-induced bearing damage.

Application Scenario 2: Non-Drive End (NDE) of Motors

- Operating Conditions: The non-drive end (NDE) typically handles lighter loads but must accommodate the axial thermal expansion of the shaft during operation. As a key support point, its running accuracy directly impacts the motor’s overall vibration and noise levels.

- TFL Recommended Solution: High-Precision Deep Groove Ball Bearing (P5 Class, C3 Clearance)

We recommend a P5 precision class bearing to ensure superior rotational accuracy, minimizing vibration and noise. A C3 clearance provides the necessary internal space to accommodate thermal expansion, preventing internal preloading and premature failure. Paired with a high-performance, low-noise grease, this solution ensures smooth and quiet motor operation.

Core Product Overview - Bearing Quick-Reference Table for Motors

| Application Part | Bearing Type | Common Part Numbers (Examples) | Key Features |

| VFD Motor Drive End (DE) | Insulated Deep Groove Ball Bearing | 6222/C3VL0241, 6318/C3VL2071 | Outer ring Al₂O₃ coating, >3kV DC insulation, fully interchangeable with standard bearings. |

| Motor Non-Drive End (NDE) | High-Precision Deep Groove Ball Bearing | 6215-2Z/C3P5 | P5 precision class, C3 clearance, low-noise design, dual metal shields. |

| High-Speed/High-Efficiency | Hybrid Ceramic Ball Bearing | HC6210-M-P5-C3 | Si₃N₄ ceramic balls, >40% higher speed capability, natural insulator, low friction. |

| General Purpose Motors | Enhanced Deep Groove Ball Bearing | 6314-2RS/C3EMQ | Optimized raceway geometry, high-performance polymer cage, specialized motor grease, robust seals. |

TFL Boosts Paper Machine Reliability, Maximizing Production Uptime

TFL solved a paper mill's VFD motor failures from electrical erosion. By providing insulated and hybrid ceramic bearings, they extended bearing life, cut costs, and boosted operational reliability.

Investing in Reliability is an Investment in Productivity

In the total lifecycle of a high-efficiency motor, the initial cost of a bearing is minimal. Yet, its performance dictates the reliability and efficiency of the entire machine. Choosing TFL high-performance bearings—engineered specifically to combat electrical erosion, high temperatures, and high speeds—is a strategic investment in lowering your Total Cost of Ownership (TCO). It not only prevents expensive failures and downtime but also ensures your core assets continue to generate value.