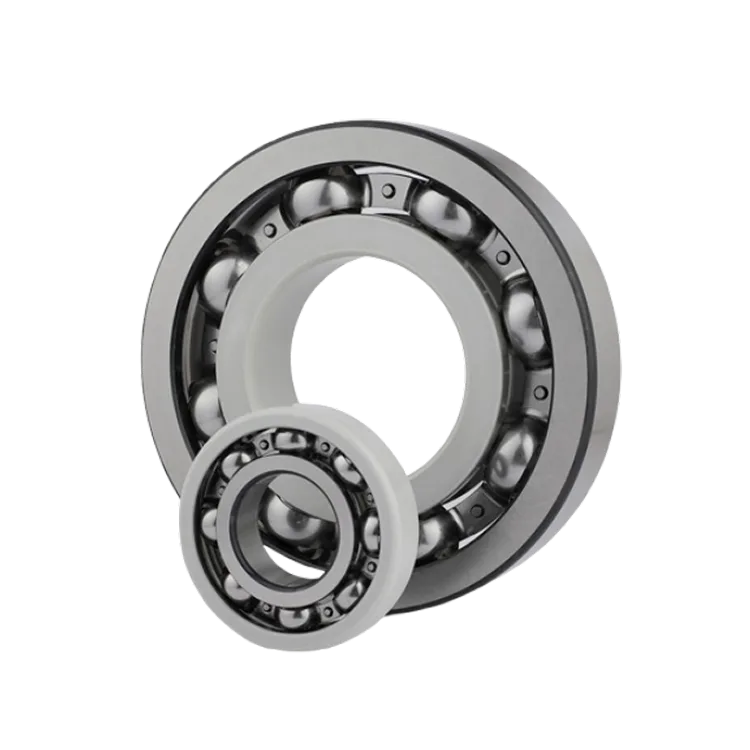

High-Performance Bearing Solutions for Demanding Motor Applications

Electric motors are the heart of modern industry, and their consistent performance is fundamental to overall system productivity. From high-speed precision servos to heavy-duty industrial motors in continuous operation, today’s applications demand the utmost in efficiency, low noise and vibration (NVH), and long-term reliability. Any unplanned downtime can result in significant production losses.

At TFL, we understand these challenges intimately. We don’t just manufacture bearings; we engineer performance safeguards for the core of your motor. By leveraging advanced raceway superfinishing, specialized low-noise grease, and innovative cage and seal designs, TFL’s solutions fundamentally reduce frictional losses, suppress vibration, and provide robust insulation protection in complex electrical environments like VFDs. We empower our clients to achieve lower energy consumption, longer maintenance intervals, and a superior Total Cost of Ownership (TCO).

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

High-Efficiency Industrial Motors

Choosing TFL high-performance bearings—engineered specifically to combat electrical erosion, high temperatures, and high speeds—is a strategic investment in lowering your Total Cost of Ownership (TCO).

Electric Motors

Key Technical Applications of TFL Bearings in High-Efficiency Industrial Motors

In the global push for higher energy efficiency, every watt of power saved matters. High-efficiency motors require bearings with exceptionally low friction. TFL provides deeply optimized deep groove ball bearings with...

Key Technical Applications of TFL Bearings in Variable Frequency Drive (VFD) Motors

Stray shaft currents generated by VFDs are a leading cause of premature bearing failure. This electrical erosion creates irreversible raceway damage. TFL offers specialized insulated bearings, including...

Key Technical Applications of TFL Bearings in Servo Motors

Servo systems demand exceptional dynamic response, positioning accuracy, and smooth operation. Their bearings must withstand frequent start-stop cycles, rapid acceleration, and precise positioning...

Key Technical Applications of TFL Bearings in Pump & Fan Motors

Often operating in environments with high humidity, dust, and corrosive elements, these motors are the ultimate test of a bearing's defense system. Contaminant ingress and lubrication failure are primary failure modes...

Far More Than This

Electric Motors Applications

Application List

Transportation & E-Mobility

- EV Traction Motors

- Rail Transit Traction Motors

- Automotive Auxiliary Motors (e.g., for wipers, seats, fans)

- E-Bike/E-Scooter Hub Motors

Industrial Automation & Robotics

- Stepper Motors

- Linear Motors

- Robot Joint Motors

- High-Speed Spindle Motors

Appliances & Power Tools

- HVAC Compressor Motors

- Power Tool Motors

- White Goods Motors (e.g., for washing machines)

- Garden Tool Motors

Special & Purpose-Built Motors

- Elevator Traction Motors

- Explosion-Proof Motors

- Vibrating Motors

- Crane & Metallurgical Motors

TFL Bearings Help German Customer Increase Servo Motor Efficiency Fivefold

TFL supplied a German servo motor maker with P5/ZV3 precision bearings, solving their supply issues. This enhanced motor performance and secured a long-term partnership, improving product reliability.

TFL’s Ultra-Quiet Motor Bearings: The Preferred Choice for Global Brands Sourcing from China

TFL's Motor Bearings offer ultra-quiet performance, durability, and cost efficiency, making them the top choice for global brands sourcing from China.

Frequently Asked Questions for the Motor Industry

How exactly do TFL's insulated bearings prevent electrical erosion in VFD motors?

TFL's high-performance bearings may have a higher initial cost. What is the long-term Return on Investment (ROI)?

- Energy Savings: Lower friction directly translates to reduced energy consumption and lower electricity bills.

- Reduced Maintenance: Superior longevity and reliability lead to fewer instances of unplanned downtime, longer service intervals, and lower replacement part costs.

- Improved System Performance: Low noise and vibration (NVH) characteristics enhance the quality and marketability of your final product.

For motors in dusty or wet environments, what is the best approach to lubrication and sealing to maximize bearing life?

Can TFL bearings be used as direct replacements for other major brands (e.g., SKF, NSK) in our existing motors?

Absolutely. All TFL standard bearings are manufactured in strict accordance with ISO (International Organization for Standardization) standards. This ensures that their key dimensions—bore, outer diameter, and width—are fully interchangeable with all major global brands. You can confidently use TFL products as drop-in replacements, and we can provide detailed cross-reference charts to help you find the exact TFL equivalent.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Maximize Your Motor's Efficiency and ROI

For electric motors, the cheapest bearing often leads to the highest lifetime costs. A precision-engineered, high-performance bearing is a strategic investment that delivers unmatched value through enhanced energy efficiency, quieter operation, and superior reliability, ensuring less downtime and a lower total cost of ownership.