Compressors

High-Performance Bearing Solutions for Compressor Applications

As the power source for countless industrial processes, the consistent operation of a compressor directly impacts production efficiency and profitability. However, demanding conditions such as high speeds, heavy loads, extreme temperatures, and corrosive media constantly challenge the performance and lifespan of its most critical components: the bearings. Any unplanned downtime can result in significant financial losses.

At TFL, we understand these challenges intimately. Leveraging decades of industry experience and continuous innovation in material science and precision manufacturing, we deliver bearing solutions that exceed standard requirements. We are committed to translating advanced bearing technology into measurable business value for our customers: longer Mean Time Between Failures (MTBF), reduced energy consumption, and a significantly lower Total Cost of Ownership (TCO).

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

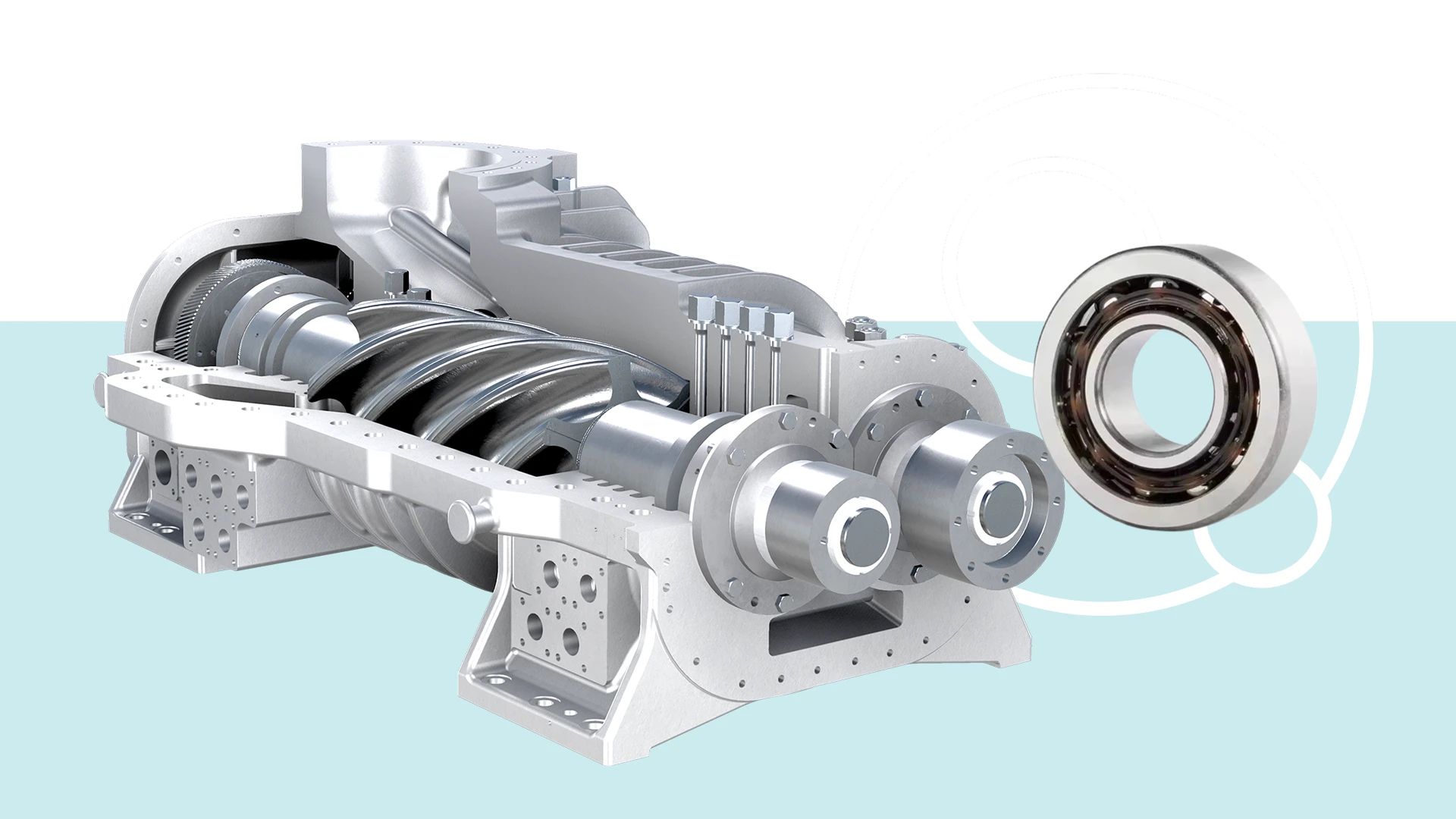

Screw Compressor

Discover how specialized bearings ensure screw compressor efficiency, durability, and low maintenance. Find the right solutions.

Compressor Bearing

Compressors, such as screw, centrifugal, and reciprocating types, operate in demanding environments involving continuous high-speed rotation, significant temperature increases, and heavy axial and radial loads. They must also endure constant vibration and face potential contamination from refrigerants, process gases, moisture, or wear particles. Therefore, their bearings must deliver exceptional high-speed performance, excellent temperature resistance, and a very high load-carrying capacity to ensure long-term, reliable operation under these harsh conditions.

Key Technical Applications of TFL Bearings in Screw Compressors

The primary challenge in screw compressors is maintaining precise clearance between the male and female rotors while managing immense axial forces from pressure differentials. TFL provides high-rigidity, high-precision cylindrical roller bearings...

Key Technical Applications of TFL Bearings in Centrifugal Compressors

Known for their ultra-high speeds, centrifugal compressors demand the highest levels of dynamic stability, heat dissipation, and speed capability from their bearings. TFL's high-speed series of angular contact ball bearings...

Key Technical Applications of TFL Bearings in Air Compressors

As the workhorse of industry, air compressors often run 24/7, making reliability paramount. The high temperatures from continuous operation and potential environmental contaminants pose a severe test for bearings...

Key Technical Applications of TFL Bearings in Vacuum Pumps

Vacuum pumps operate in unique environments, especially in high-purity applications like semiconductor manufacturing and scientific research. Bearings must perform under starved lubrication or oil-free conditions, at high speeds, and...

Far More Than This

Compressor Bearing Applications

Application List

By Structure & Application

- Reciprocating Compressors

- Scroll Compressors

- Roots Blowers

- Blowers

- Boosters

By Gas Medium

- Process Gas Compressors

- Refrigeration Compressors

- Natural Gas Compressors

TFL Boosting Screw Compressor Rotor Reliability and Cutting Unplanned Downtime by 50%!

TFL offers custom bearing solutions for screw compressors to combat failures from high speed, heat, and loads. Their bearings use optimized designs and special materials to extend service life and boost reliability.

For a high-speed, oil-free centrifugal compressor, should I choose angular contact ball bearings or cylindrical roller bearings for the main shaft?

This is a classic application trade-off. While cylindrical roller bearings offer excellent radial load capacity and rigidity, centrifugal compressors also generate significant axial loads. We therefore highly recommend using a matched pair of high-precision angular contact ball bearings. They can accommodate both radial and axial loads simultaneously and, when preloaded, provide the high system rigidity needed to maintain the tight clearances between the impeller and diffuser, which is crucial for compressor efficiency and stability.

What are the specific advantages of TFL's PEEK cages over traditional metal cages in refrigeration compressors?

PEEK (Polyetheretherketone) cages are a hallmark of TFL's solutions for demanding applications. In refrigeration compressors, the benefits are clear:

- Superior Chemical Compatibility: PEEK is resistant to aggressive refrigerants (e.g., R134a, R410A) and lubricants without degrading.

- Low Friction & Self-Lubricating: It provides better protection in marginal lubrication conditions, reducing operating temperatures.

- Lightweight: A lighter cage reduces centrifugal forces, allowing the bearing to achieve higher speeds with lower energy consumption.

TFL's high-performance bearings have a higher initial cost. How do I justify the long-term value to my management?

This is a key question about Total Cost of Ownership (TCO). You can build a strong case based on three points:

- Extended Service Intervals: TFL bearings use superior materials and precision manufacturing, resulting in a longer operational life, which means fewer overhauls and spare part purchases.

- Reduced Downtime Losses: In a critical process, the cost of one unplanned shutdown (lost production, labor, contract penalties) can dwarf the cost of the bearing itself. TFL's reliability is insurance against these costly events.

- Improved Energy Efficiency: Our low-friction designs reduce the compressor's energy draw, leading to substantial electricity savings over time. The value of TFL is in maximizing your uptime and lowering your operational costs.

The bearings in our screw compressors often fail prematurely due to contaminated lubricant. What solutions does TFL offer?

Lubricant contamination is a leading cause of premature bearing failure. Beyond recommending high-quality filtration and regular oil changes, TFL can provide bearing solutions with integrated high-performance seals. These specially designed seals effectively block metallic debris, moisture, and other contaminants from entering the raceways. For extremely contaminated environments, we can also offer more advanced solutions like labyrinth or non-contact seals to protect the bearing at its source.

My equipment is from Atlas Copco / Ingersoll Rand. Can TFL bearings be used as direct replacements for their OEM parts?

Absolutely. TFL bearings are manufactured to strict ISO standards, and many of our product lines are 100% dimensionally interchangeable with those from major OEMs, including Atlas Copco, Ingersoll Rand, Sullair, and others. Furthermore, through material upgrades and optimized designs, our replacement bearings often meet or exceed the original specifications in terms of performance and lifespan. Our technical team can cross-reference your OEM part number or equipment model to provide a precise TFL equivalent or an upgraded solution.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Boost Compressor Efficiency and Lower Operating Costs

For industrial compressors, a standard bearing often increases your total cost of ownership through energy loss and downtime. A high-performance bearing, engineered for this application, is an investment that provides a powerful return through improved efficiency, enhanced reliability, and a significantly extended service life.