Long-Life Bearing Solutions for Injection Molding Clamping Units

The Clamping Unit is the “muscle” of an injection molding machine. Its main job is to hold the mold closed against the high pressure of injecting plastic. It also opens and closes the mold precisely. Common types include Toggle Mechanisms, Hydraulic Rams, and Electric Drives. These units are critical in automotive, medical, and consumer goods manufacturing.

Modern production demands faster cycle times and higher clamping forces. This creates extreme stress. Clamping units face frequent start-stop cycles, high-frequency oscillation, and massive shock loads. These conditions often prevent a proper oil film from forming in the bearings. This leads to rapid wear and machine downtime.

TFL Bearings offers a specialized solution for these tough conditions. We use advanced tribology (friction science) to create bearings specifically for injection molding. Our designs feature reinforced materials, optimized internal geometry, and special surface treatments.

Switching to TFL solutions brings clear benefits. You eliminate “fretting wear” issues. You extend the time between maintenance checks. Ultimately, you lower your Total Cost of Ownership (TCO) and keep your machines running longer.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool

Electric Motors

Metallurgical Industry

Industrial Pumps

Compressors

Food & Beverage Machinery

Plup and Paper

Plastic Machinery

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Why Do Clamping Unit Bearings Fail?

Unlike electric motors that rotate continuously, the clamping mechanism performs high-frequency Oscillating Motion. Under these conditions, a hydrodynamic lubrication film cannot be fully established, leaving the bearing in a state of Boundary Lubrication.

Combined with hundreds of tons of clamping force and shock loads during mold opening, standard bearings are prone to Fretting Wear and seizure. TFL redefines reliability by optimizing lubrication groove designs and applying surface phosphating treatments.

Key Challenges & Solutions

Application 1: Toggle Linkage System

Condition Analysis: This is the most critical area. The pins bear huge locking forces. The motion is a small, back-and-forth oscillation. This movement breaks the oil film, causing severe wear. Space is also very tight.

TFL Recommendation: Needle Roller Bearings (Solid Ring or Cage Assembly)

- High Load Capacity: Our needle rollers use a modified line contact design. They handle extreme loads in very small spaces.

- Anti-Fretting Design: We optimize the clearance to handle oscillation. When paired with TFL anti-fretting grease, the oil film stays intact.

- Reinforced Cage: We use high-strength steel cages to survive the constant shock of opening and closing.

Application 2: Mold Height Adjustment Mechanism

Condition Analysis: This part adjusts the backplate for different mold thicknesses. It is mostly static (still). However, it must hold the full clamping force without moving or deforming.

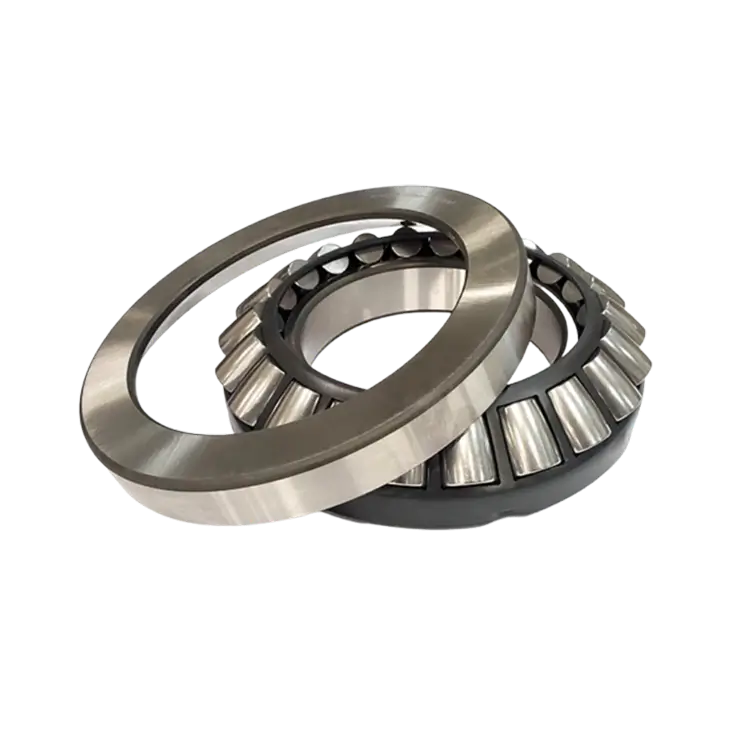

TFL Recommendation: Spherical Roller Thrust Bearings

- High Axial Stiffness: These bearings are heat-treated for stability. They do not deform under the massive pressure of locking.

- Self-Aligning: They can compensate for slight bending in the machine frame. This prevents edge stress and early failure.

Application 3: Moving Platen Guidance

Condition Analysis: The moving platen slides back and forth on tie bars. It carries the heavy mold. It needs smooth motion to prevent the mold from sagging and damaging the guide pins.

TFL Recommendation: Self-lubricating Composite Bushings

- Maintenance-Free: These bushings use a PTFE composite layer. They are self-lubricating. This keeps the tie bars clean and prevents oil form contaminating your products.

- Shock Absorption: The composite material absorbs vibration. This protects your expensive tie bars from scratches.

Application 4: Ejector System

Condition Analysis: The ejector pins push the finished part out. This action is fast and repetitive. The bearings need low friction and quick response times.

TFL Recommendation: Deep Groove Ball Bearings (Sealed Version)

- Low Friction: Optimized raceways ensure the ejector moves quickly and stays cool.

- Sealed Protection: We use high-performance 2RS seals. They block plastic dust and sprays from entering the bearing, extending service life significantly.

Product Overview: Quick Reference Guide

| Application Part | Bearing Type | Common Part Numbers (Examples) | Key Features |

| Toggle Linkage (Pins) | Needle Roller | NK / NKI Series, NA 48 / 49 Series | High load, compact, anti-oscillation wear |

| Crosshead Guide | Cylindrical Roller | NU 2xx ECP, NJ 2xx ECP | Heavy load, separable, easy installation |

| Mold Adjustment | Thrust Bearing | 511xx / 512xx (Ball), 293xx (Roller) | Handles massive axial static loads |

| Ejector Screw/Motor | Angular Contact Ball | 72xx BEP, 73xx BEP | Handles combined loads, high speed |

| Safety Door Guide | Linear Bearing | LME / LM Series | Low friction, smooth motion |

Note: Final bearing selection depends on specific load, speed, and dimensional requirements. Please consult a TFL application engineer for a precise recommendation.

Reliability is Productivity

In injection molding, the stability of the clamping unit defines your product quality. Choosing generic bearings might save a few dollars upfront. However, frequent downtime, worn toggle pins, and poor mold alignment cost thousands in lost production.

TFL high-performance bearings are an investment in uptime. We solve the specific problems of oscillation and shock load. This gives you a lower cost per part and higher machine availability.