High-Performance Bearing Solutions for Plastic Machinery

In the plastic industry, equipment reliability is your bottom line. From the high clamping forces of Injection Molding Machines to the continuous torque of Extruders and the abrasive dust in Granulators, your bearings face extreme operational stress.

At TFL, we deliver application-specific bearing solutions engineered to withstand heat, contamination, and shock loads. Our products are designed to:

-

Extend MTBF: Significantly reduce unplanned maintenance downtime.

-

Resist Contamination: Advanced sealing against plastic particulates.

-

Handle Heavy Loads: Reinforced cages for high-speed & high-load stability.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Injection Molding Clamping Units

Facing wear or misalignment in clamping units? Discover long-life bearing solutions that boost stability and reduce downtime in injection molding.

TFL Bearings: Overcoming Extreme Conditions in Plastic Processing

In the plastic machinery industry, from the toggle mechanisms of injection molding machines to the gearboxes of extruders, equipment faces extreme axial loads, shock loads, and high temperatures. Standard bearings often fail prematurely in crushing and recycling applications due to dust ingress. Leveraging years of industry experience, TFL provides solutions with high rigidity and durability through optimized cage designs and reinforced sealing technologies. Whether for new equipment OEM or maintenance (MRO), we precisely match your operational requirements.

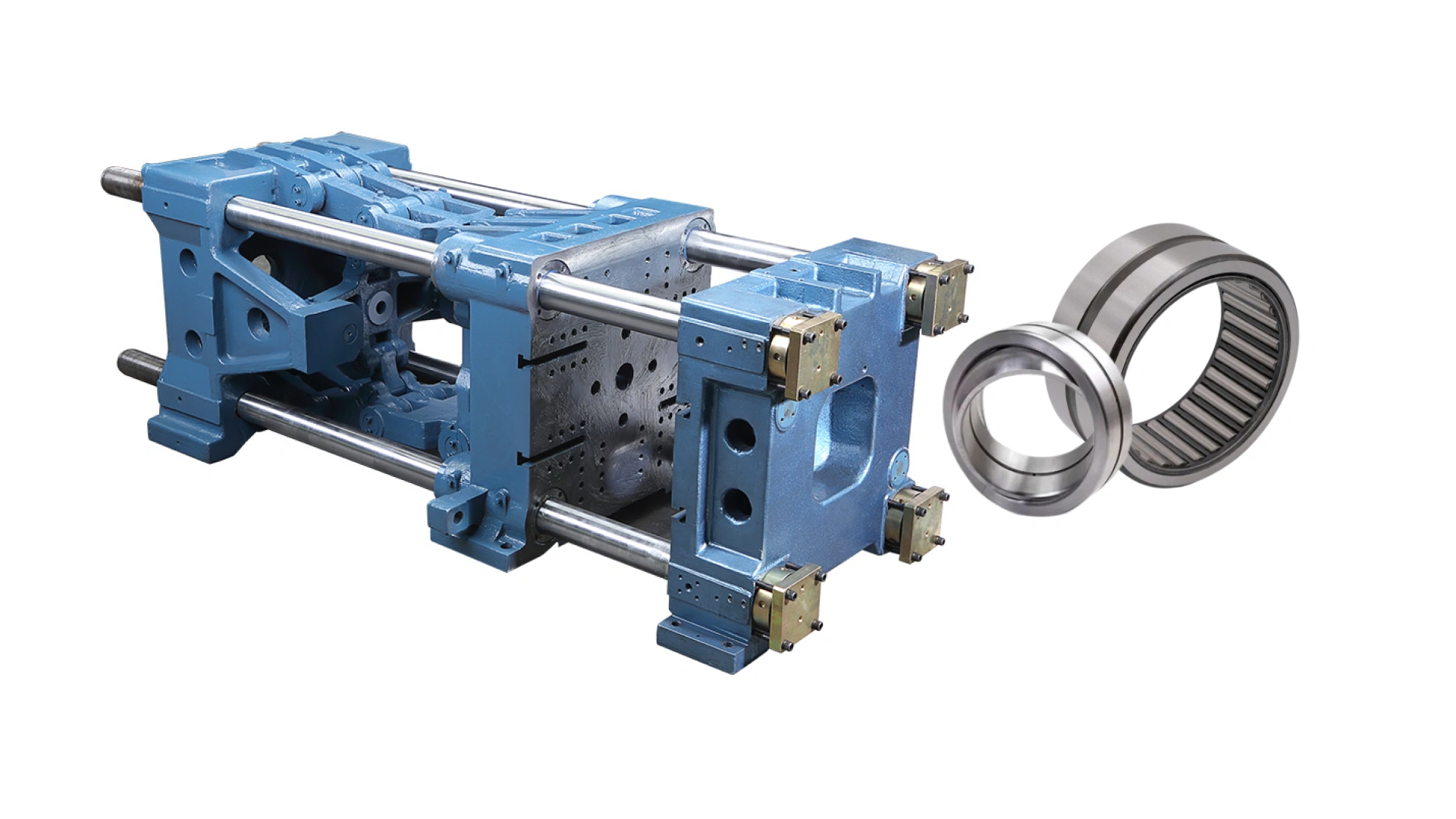

Bearings for Injection Molding Clamping Units

The toggle system of an injection molding machine endures massive reciprocating shock loads during mold opening and closing. TFL provides high-strength Needle Roller Bearings and Self-lubricating Spherical Plain Bearings with excellent wear resistance, effectively handling high-frequency vibrations and ensuring clamping precision.

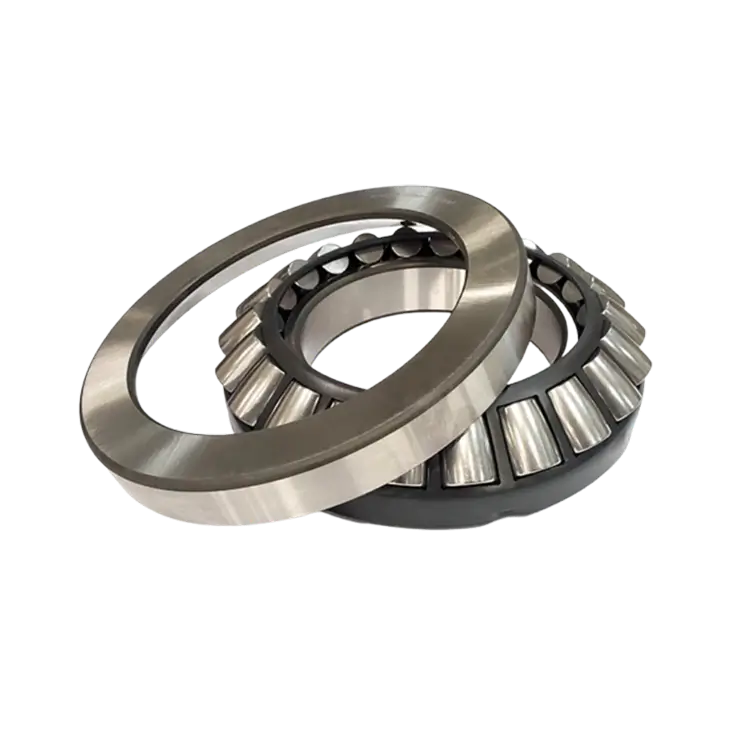

Thrust Bearings for Extruder Gearboxes

Extruder screws generate immense reverse axial forces when pushing molten plastic. TFL's optimized Thrust Spherical Roller Bearings (294 Series) feature machined brass cages and super-finished raceways, ensuring smooth operation under heavy loads and high temperatures.

High-Vibration Bearings for Plastic Granulators

Crusher rotor shafts face violent shocks and heavy dust when cutting plastic waste. We recommend Spherical Roller Bearings with reinforced seals and impact-resistant cages to effectively prevent plastic powder ingress, preventing bearing seizure and overheating.

Bearings for Film Blowing Machine Rollers

Film production requires extreme stability to ensure uniform film thickness. TFL offers low-noise, low-friction torque Deep Groove Ball Bearings, ensuring smooth operation of traction and guide rollers to elevate the quality of your finished film products.

Far More Than This

Plastic Machinery

Application List

Raw Material Handling & Recycling

- Plastic Granulators / Crushers

- Industrial Shredders

- Plastic Mixers / Dosers

- Dehumidifying Dryers

- Auto Loaders

Auxiliary & Automation

- Robotic Arms / Take-out Robots

- Mold Temperature Controllers

- Industrial Chillers

- Belt Conveyors

- Central Feeding Systems

Post-Processing & Finishing

- Slitter Rewinders

- Thermoforming Machines

- Bag Making Machines

- Pipe Haul-offs / Pullers

- Plastic Printing Machines

The thrust bearing behind my extruder screw fails frequently. Does TFL offer a reinforced solution?

Yes.

This is a common failure mode. TFL offers E-type High-Load Thrust Spherical Roller Bearings, featuring optimized contact angles between rollers and raceways. Load capacity is increased by 15%-20% over standard types, specifically designed to withstand early failures caused by high screw back-pressure.

Can TFL bearings directly replace OEM bearings on Haitian or Engel injection molding machines?

Yes.

Our products adhere to ISO dimensional standards and are 100% interchangeable with spare parts for major machine brands like Haitian, Engel, and Arburg. We can provide accurate cross-reference replacements based on your existing bearing part numbers.

What sealing is recommended for the high-dust environment of plastic granulators?

For granulators, we recommend TFL bearings with Tri-lip Seals or housed bearing units with dust caps. For extremely harsh conditions, we also advise regular relubrication with contamination-resistant grease to create an oil barrier against dust ingress.

What is your Lead Time for delivery?

For common series used in the plastics industry (such as 294 series thrust bearings or 222 series spherical roller bearings), we maintain ample stock and can ship within 10 days to minimize your unplanned downtime.

Do you offer customization services?

Sure.

We can provide high-temperature bearings (200℃+) or special coated bearings tailored to your specific needs for processing specialized engineering plastics.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Ready to Optimize Your Plastic Machinery Performance?

Don't let bearing failures slow down your production. Contact TFL industry experts today for a free application analysis and a cost-effective replacement proposal.