High-Performance Bearing Solutions for Harsh Pulp & Paper Conditions

The paper industry operates under some of the most challenging conditions in manufacturing. Equipment must contend with extreme humidity, corrosive chemicals, intense heat, and continuous high-speed operation. A single bearing failure in a critical roll can halt the entire production line, leading to massive financial losses.

We combine advanced material science with precision engineering to create paper machine bearings specifically designed for the pulp and paper workflow. Whether it is Corrosion resistant bearings for bleaching towers or specialized High temperature bearings for dryer sections, TFL helps mills reduce Total Cost of Ownership (TCO) and maximize machine run-ability.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Pulping & Preparation Equipment

Dealing with moisture, shock loads or early wear in pulping systems? Find durable bearings built to handle tough preparation stages with stability.

Paper Machine Bearing

Paper manufacturing equipment, encompassing pulpers, press rolls, dryer cylinders, and high-speed winders, operates in punishing environments characterized by extreme humidity, corrosive chemical exposure, and intense heat. These systems face rigorous challenges, including massive radial loads during pressing, thermal expansion in drying zones, and the constant threat of contamination from water, acidic pulp, and paper dust. Consequently, paper machine bearings must possess superior corrosion resistance, robust sealing capabilities, and exceptional thermal stability, alongside immense load-carrying capacity, to ensure continuous, downtime-free production amidst these severe operational extremes.

Key Technical Applications of TFL Bearings in Pulping & Preparation Equipment

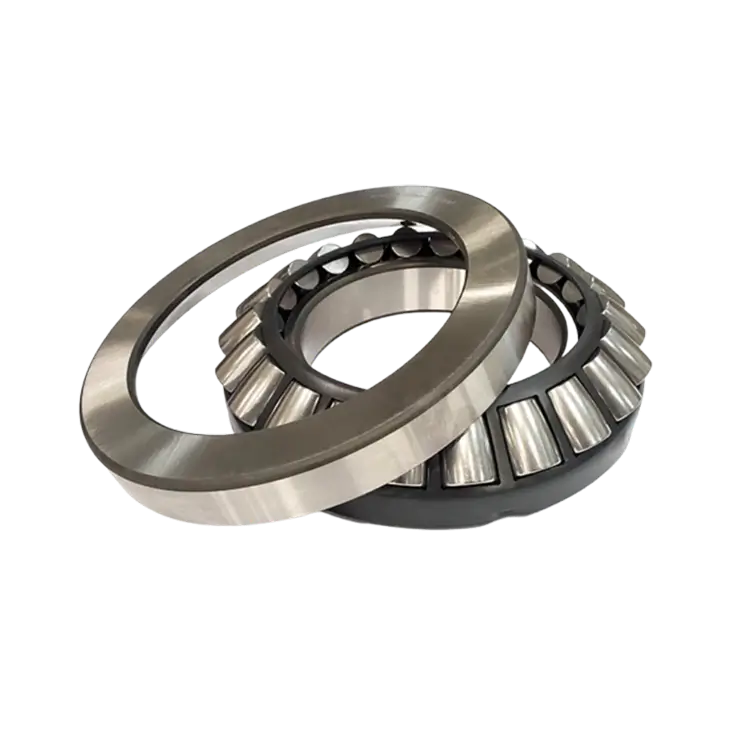

From chippers to digesters, the pulping process involves heavy shock loads and highly corrosive chemical environments. Bearings here must survive impact and chemical ingress. TFL offers robust roller bearings...

Key Technical Applications of TFL Bearings in Wet End & Press Section

The forming and press sections require bearings that can operate in water-saturated environments while supporting heavy rolls. TFL’s Press roll bearing solutions feature superior sealing...

Key Technical Applications of TFL Bearings in Drying Section

As the paper sheet moves to the drying cylinders, temperatures soar. Standard bearings fail quickly under this thermal stress. TFL provides specialized Dryer cylinder bearings...

Key Technical Applications of TFL Bearings in Finishing & Converting

In calenders, winders, and coaters, precision and speed are paramount. Vibration can lead to poor paper quality or web breaks. TFL utilizes high-precision angular contact ball bearings and...

Far More Than This

Paper Machinery

Application List

Raw Material Handling

- Debarkers

- Conveyors

- Refiners

Pulp Processing

- Pressure Screens

- Washers & Thickeners

- Bleaching Towers

- De-inking Cells

Converting & Finishing

- Slitter Rewinders

- Sheeters/Cutters

- Coating Machines

- Embossing Machines

TFL bearing solution saves $136,000 Annually on Paper machine!

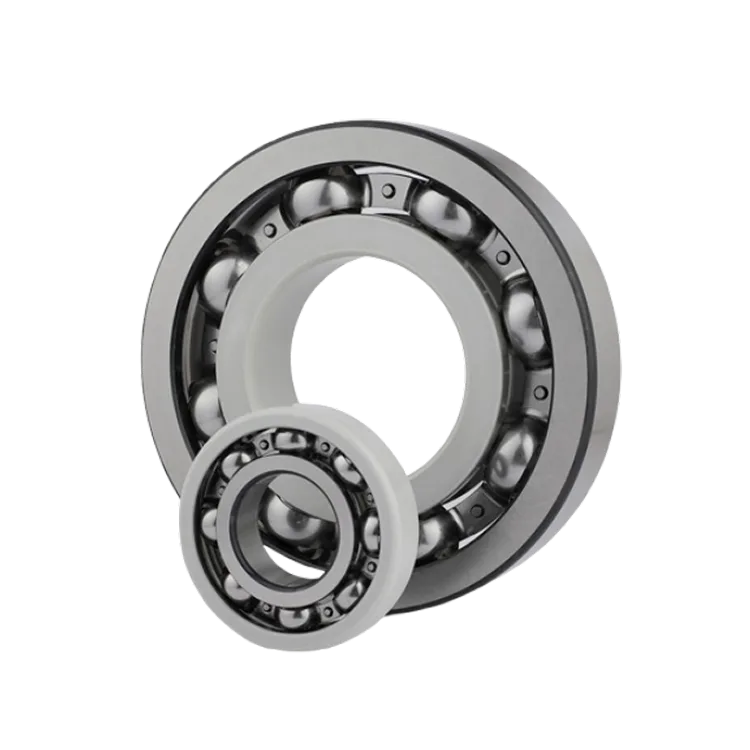

TFL resolved random bearing failures in paper machine VFD motors caused by shaft currents—leading to unpredictable downtime—by installing electrically insulated deep groove ball bearings, which enhanced reliability and delivered annual savings of $136,000 through reduced spare parts, downtime, and scrap costs.

How does TFL address bearing failure in the wet end caused by water ingress?

We utilize specialized sealing structures and high-performance grease specifically designed for wet environments. For critical positions like suction rolls, we offer bearings with enhanced corrosion resistance and sealing capabilities to prevent moisture from washing out the lubricant, effectively extending service life.

What makes TFL's Dryer Cylinder Bearings different from standard bearings?

TFL Dryer cylinder bearings are manufactured using case-hardened steel or bainitic hardened steel that undergoes special heat treatment to remain dimensionally stable up to 200°C (depending on the specific grade). We also calculate optimal C3 or C4 radial internal clearances to accommodate thermal expansion, preventing seizing during operation.

Are your paper machine bearings compatible with bleaching equipment using harsh chemicals?

Yes. For environments exposed to bleach and other corrosive agents, we recommend our Corrosion resistant bearing series. These utilize stainless steel, ceramic hybrid elements, or specialized coatings to resist chemical attack, ensuring reliability in agitators and mixers within the bleaching tower.

How can switching to TFL paper machine bearings reduce our Total Cost of Ownership (TCO)?

While the initial price is a factor, the cost of unscheduled downtime in a paper mill far exceeds component capability. By using application-specific bearings (like our heavy-duty Press roll bearing), we extend Mean Time Between Failures (MTBF). Fewer replacements mean less downtime and lower maintenance labor costs, significantly reducing TCO over time.

Can TFL provide bearings for high-speed winders requiring precise tension control?

Absolutely. For the finishing section, stability is key. We offer high-precision Guide roll bearings (typically Cylindrical Roller or Deep Groove Ball types) with optimized internal geometry to handle high speeds with low friction and vibration. This helps maintain constant web tension and prevents paper defects.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Ready to Enhance Your Paper Machine Performance?

Choosing a TFL specialized paper machine bearing isn't just a purchase; it’s a strategic investment in continuous tonnage. The initial cost reflects the advanced engineering required to survive searing heat and corrosive pulp slurry. In return, you get a machine that maintains speed and stability, maintenance crews that can focus on optimization rather than emergency firefighting, and the confidence that your roll alignments will hold true. It’s an investment that validates itself the moment you breeze past a scheduled maintenance window without a single unplanned stop.