Enhancing Centrifugal Pump Reliability with High-Performance Bearing Solutions

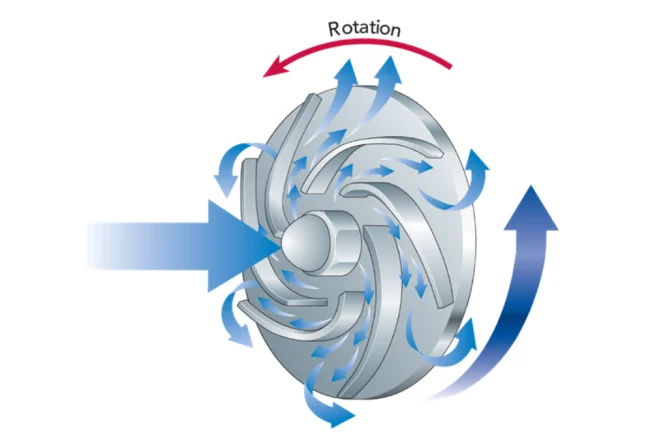

A centrifugal pump (cent. pump) is a mechanical device that uses a rotating impeller to move fluids, serving as the heart of countless industrial processes. These pumps are essential in sectors like petrochemicals, water treatment, power generation, and mining, where their consistent operation is critical to overall system uptime.

The primary challenge is the harsh operating environment. Centrifugal pumps subject their bearings to a punishing combination of high rotational speeds, dynamic radial and axial loads, vibration, and fluctuating temperatures. These conditions lead to premature wear and catastrophic failure, causing unplanned downtime, significant production losses, and expensive repairs.

TFL offers a comprehensive range of high-performance centrifugal pump bearing solutions engineered specifically for these demanding conditions. By leveraging advanced materials, optimized internal geometry, and precision manufacturing, we directly address the root causes of pump failure to fundamentally improve equipment reliability and lifespan.

Partnering with TFL delivers tangible benefits: significantly increased Mean Time Between Failures (MTBF), reduced maintenance frequency and costs, improved energy efficiency, and a lower Total Cost of Ownership (TCO).

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool

Electric Motors

Metallurgical Industry

Industrial Pumps

Compressors

Food & Beverage Machinery

Plup and Paper

Plastic Machinery

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Common Pump Bearing Problems in Centrifugal Pumps

Premature pump bearing failure in centrifugal pumps is rarely caused by a single issue. It is often the result of a combination of factors including design, installation, lubrication, and operating conditions. Understanding these failure modes is the first step toward effective prevention and enhanced reliability.

Common Problems List

| Failure Mode | Symptoms | Primary Causes |

| Abrasive Wear | Dull, unpolished surfaces on raceways and rolling elements; increased internal clearance. | Lubricant contaminated with hard particles (e.g., dirt, metal debris) that grind down surfaces. |

| Fatigue Spalling | Micro-cracks on the surface of raceways or rollers, which develop into flaked or pitted areas. | Bearing load exceeds its fatigue limit, often due to overload, improper installation, or end of service life. |

| Corrosion | Red or black rust spots and pitting on bearing surfaces, often accompanied by increased vibration. | Ingress of water or corrosive agents that break down the lubricant film and attack the metal. |

| Overheating | Discoloration of rings, rollers, and cage, ranging from yellow/brown to a dark blue. | Inadequate lubrication, excessive preload, or very high speeds generating more friction heat than can be dissipated. |

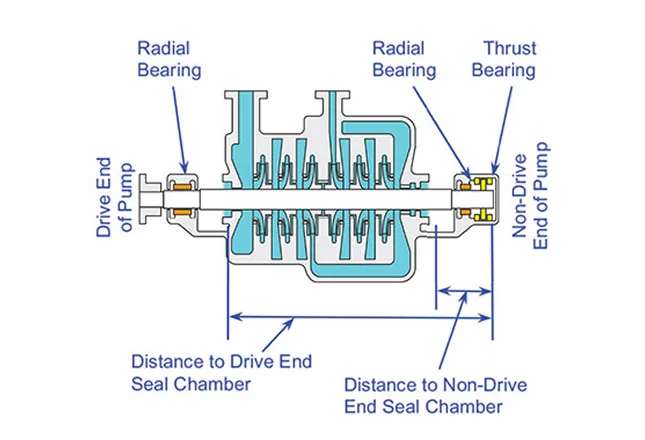

Application Analysis for Centrifugal Pump

For the complex and demanding conditions found in centrifugal pumps, we offer proven, high-performance centrifugal pump bearing solutions for each critical position:

Application 1: Drive End (Primarily Radial Loads)

- Operating Conditions: This position primarily supports radial loads from the motor coupling or belt drive while accommodating high rotational speeds. It is sensitive to misalignment between the pump and motor shafts, which can introduce damaging vibration and bending moments.

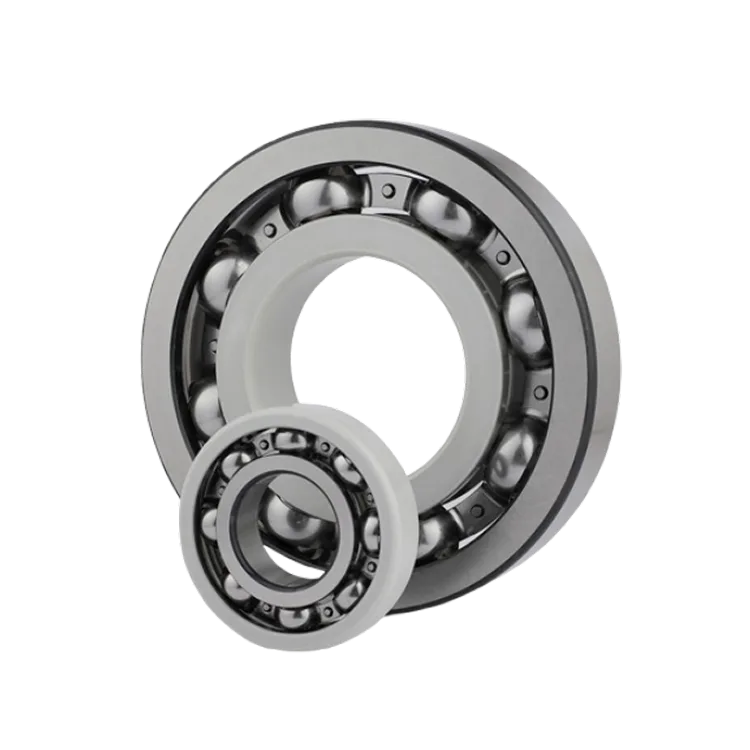

- TFL Recommended Solution: High-Precision Deep Groove Ball Bearing

We recommend a deep groove ball bearing with a higher precision class (P6 or better) and optimized design. Its point-contact geometry ensures low friction for high-speed operation, while the optimized raceway provides excellent radial load capacity. A robust cage and high-quality grease ensure stability and long life.

Application 2: Impeller End (Combined Loads)

- Operating Conditions: This is the most challenging bearing position in the pump. It must handle both the radial loads from the impeller and the significant axial thrust generated by fluid pressure. These combined loads are dynamic, changing with the pump’s flow rate and head, demanding high axial capacity and system rigidity.

- TFL Recommended Solution: Paired Angular Contact Ball Bearings

A back-to-back (DB) set of angular contact ball bearings is the ideal solution. This arrangement handles heavy axial loads in both directions and creates a very stiff system, minimizing shaft movement. This protects the precise clearance between the impeller and pump casing, improving pump efficiency and seal life.

Application 3: Heavy-Duty Slurry and Multistage Pumps

- Operating Conditions: Bearings in slurry pumps or high-pressure multistage pumps face extreme challenges, including massive radial loads from heavy media, severe shock and vibration, and inevitable shaft deflection under load.

- TFL Recommended Solution: Spherical Roller Bearing

The spherical roller bearing is unmatched for these conditions. Its key feature is its self-aligning capability, which accommodates shaft deflection and misalignment without creating destructive edge stresses. The double-row, line-contact design provides exceptional radial load capacity and shock resistance, ensuring robust performance in the toughest applications.

Core Product Overview: Quick Reference for Screw Compressor Bearings

| Application Part | Bearing Type | Common Part Numbers (Examples) | Key Features |

| Drive End (General) | Deep Groove Ball Bearing | 6212, 6310, | High-speed capability, low friction, versatile |

| Impeller End (Fixed) | Paired Angular Contact Ball Bearing | High axial load capacity, high system rigidity | |

| Heavy-Duty (Drive/Impeller) | Spherical Roller Bearing | Extreme radial load capacity, self-aligning, shock resistant | |

| Vertical Pump Thrust | Thrust Ball Bearing | Carries pure, heavy axial loads |

Note: Final bearing selection depends on specific load, speed, and dimensional requirements. Please consult a TFL application engineer for a precise recommendation.

TFL bearings in centrifugal pumps with 12,000 hours of trouble-free operation in practice

TFL solved pump bearing failures at a petrochemical plant. Their engineered solution extended bearing service life from 3 months to over 12, drastically cutting downtime and maintenance costs.

Investing in Reliability is Investing in Productivity

The true cost of unplanned pump downtime far outweighs the price of a bearing. In today’s competitive landscape, equipment reliability is synonymous with productivity and profitability. Choosing a TFL high-performance bearing engineered for pump applications is a strategic investment in your Total Cost of Ownership. It reduces failures at the source, extends maintenance intervals, and frees your team to focus on preventive strategies, securing a powerful competitive advantage.