High-Performance Bearings: Reliability & Efficiency for Critical Pumping Apps

From municipal water systems and chemical processing to power generation and mining, industrial pumps are the indispensable core of modern industry. However, whether conveying aggressive chemicals, abrasive slurries, or operating at extreme temperatures and pressures, pump reliability faces immense challenges. As the rotational heart of the pump, even a minor bearing failure can lead to catastrophic downtime, costly repairs, and potential safety hazards.

At TFL Bearing, we know there is no one-size-fits-all solution. We are dedicated to providing application-specific bearing technology for every unique pumping challenge. Through advanced material science, precision manufacturing, and a deep understanding of fluid dynamics, we help our clients significantly extend Mean Time Between Failures (MTBF), reduce energy consumption, and optimize their Total Cost of Ownership (TCO). Choosing TFL means partnering with an expert who can anticipate and solve your toughest challenges.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Centrifugal Pumps

Solve early wear, overheating, and frequent replacement in centrifugal pumps. Upgrade to high-reliability bearings to reduce downtime.

Industrial Pump Bearing

Industrial pumps, such as centrifugal, slurry, and multistage types, operate in highly demanding environments defined by the fluids they handle. They must endure continuous rotation while managing heavy radial loads and significant axial thrust, particularly in high-pressure applications. These systems face constant threats of contamination from corrosive chemicals, abrasive particles, and moisture, in addition to persistent vibration. Therefore, their bearings must provide exceptional load-carrying capacity, superior resistance to corrosion and wear, and robust sealing against fluid ingress to ensure long-term, reliable operation and maintain process integrity.

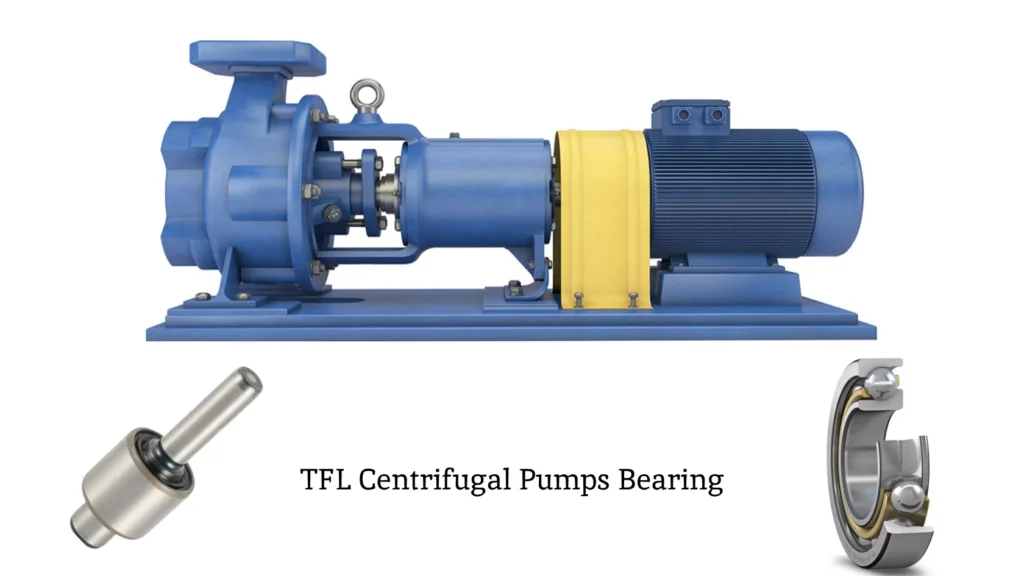

Key Technical Applications of TFL Bearings in Centrifugal Pumps

In the chemical, pharmaceutical, and food & beverage industries, centrifugal pumps must handle corrosive, high-temperature, or hygienic media. Bearings must not only withstand radial and axial loads but also resist chemical attack and high temperatures. TFL offers bearings made...

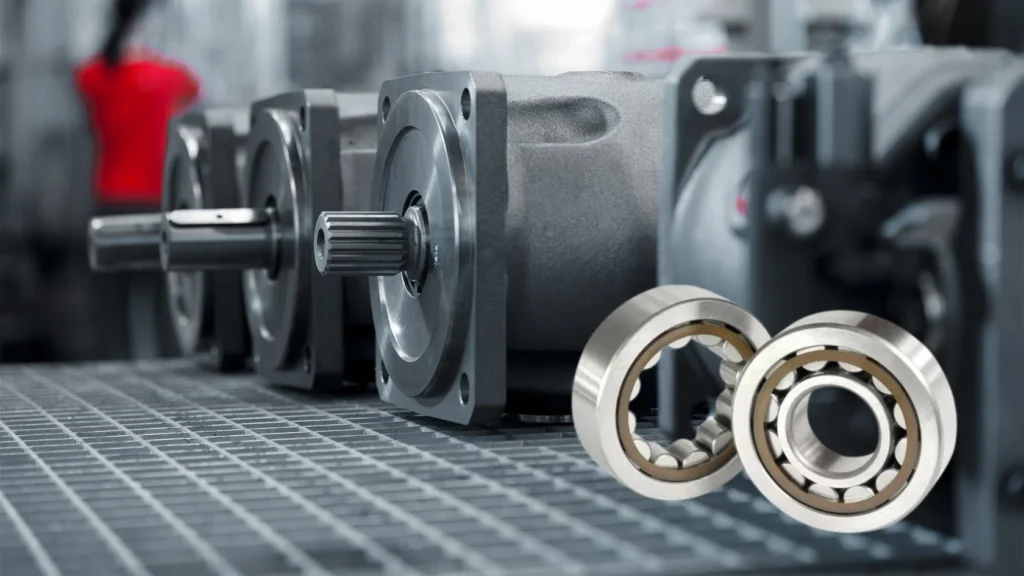

Key Technical Applications of TFL Bearings in Hydraulic Pumps

As the power source for construction machinery, industrial automation, and mobile equipment, hydraulic pumps operate under extreme pressures and speeds. The key challenges are managing immense loads within a compact space and...

Key Technical Applications of TFL Bearings in Submersible Pumps

Used in dewatering, wastewater, and deep wells, the primary challenge for submersible pumps is their complete immersion. Bearing failure is catastrophic due to the high cost of retrieval and repair. TFL provides integrated, sealed bearing units with advanced multi-lip sealing systems...

Key Technical Applications of TFL Bearings in Piston Pumps

Piston pumps generate high pressure through reciprocating motion, creating severe cyclic and shock loads on the crankshaft bearings. This demands exceptional fatigue strength. TFL delivers robust spherical roller and heavy-duty needle roller bearings with...

Far More Than This

Industrial Pumps Bearing Applications

Application List

Heavy-Duty & Severe Service

- Slurry Pumps

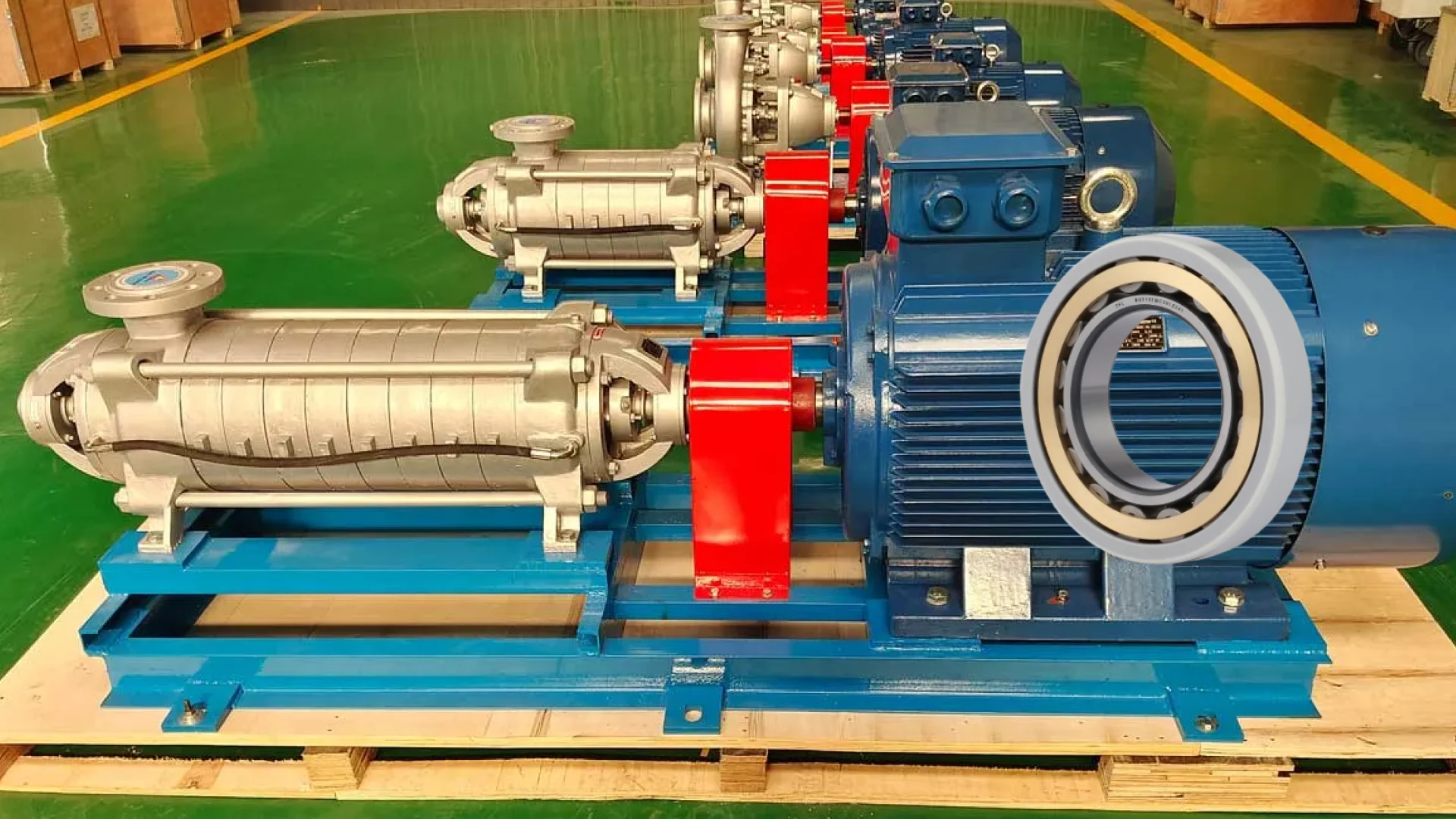

- High-Pressure Multistage Pumps

- Fire Pumps

- Magnetic Drive Pumps

Municipal & General Industry

- Wastewater Pumps

- Clean Water Pumps

- Cooling Tower Circulation Pumps

- Axial Flow Pumps

Specialized & OEM Applications

- Vacuum Pumps

- Screw Pumps

- Canned Motor Pumps

- Hygienic Pumps

TFL bearings in centrifugal pumps with 12,000 hours of trouble-free operation in practice

TFL solved pump bearing failures at a petrochemical plant. Their engineered solution extended bearing service life from 3 months to over 12, drastically cutting downtime and maintenance costs.

How should I select bearings for aggressive chemicals (acids, alkalis) versus abrasive slurries?

For corrosive chemicals, use bearings made from corrosion-resistant materials; for abrasive slurries, prioritize superior sealing. For highly corrosive media, materials like 440C stainless steel or hybrid ceramics are essential. For slurries, the key is to prevent particle ingress with robust solutions like multi-stage labyrinth seals on heavy-duty roller bearings.

What is the real benefit of TFL's "Optimized Raceway Profile" design?

The primary benefit is a significant increase in bearing service life and reliability under heavy loads. This is achieved by distributing stress more evenly across the raceway to prevent edge loading and by improving the formation of the lubricant film. The result is a bearing that runs cooler and lasts up to 20% longer in demanding pump applications.

TFL's high-performance bearings have a higher initial cost. How can I justify the lower Total Cost of Ownership (TCO)?

You justify the investment by dramatically reducing the high costs of unplanned downtime and lost production. A single pump failure can cost far more than the bearing itself. Because TFL bearings significantly extend the Mean Time Between Failures (MTBF), they reduce the frequency of costly repairs, labor, and operational losses, delivering a substantial return on investment.

In wet or washdown environments (e.g., waterworks, food processing), how can we prevent premature bearing failure from moisture ingress?

Our solution is a multi-layered defense against moisture: high-performance seals, water-resistant grease, and optional stainless steel construction. We recommend bearings with double-lip contact seals (2RS) as a first barrier, filled with a specialty grease that resists washout and emulsification. For the ultimate protection, stainless steel bearings eliminate the risk of corrosion entirely.

We use pumps from major OEMs. Can TFL provide a reliable replacement for a Sulzer pump bearing or a Flowserve pump bearing?

Yes, TFL bearings are premium, direct-fit replacements for all major OEM pump bearings. Whether you need a Sulzer pump bearing, a Flowserve pump bearing, or a replacement for a Grundfos pump bearing, our products are manufactured to strict ISO/ABMA standards for 100% dimensional interchangeability. Crucially, we offer more than just a replacement; we offer a performance upgrade, often exceeding the original part's service life through superior materials and design.

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Boost Industrial Pump Efficiency and Lower Operating Costs

For industrial pumps, a standard bearing is often a hidden liability, increasing your total cost of ownership through unplanned downtime, premature seal failure, and process contamination. A high-performance bearing, engineered specifically for pumping applications, is an investment that provides a powerful return through superior contamination resistance, unmatched operational reliability, and a significantly extended service life.