Heavy-Duty Bearings for Construction and Mining

Equipment like excavators, bulldozers, loaders, cranes, and crushers are subjected to relentless work cycles, extreme loads, constant vibration, shock impacts, and pervasive contamination from dirt, dust, water, and debris. The bearings must provide exceptional load capacity and fatigue resistance under harsh conditions.

Home / Industries / Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings in Construction & Mining

Critical Bearing Locations in Heavy Equipment

Excavator Bearings: Slewing bearings, arm joint bearings.

Bulldozer Bearings: Track roller bearings, idler bearings.

Crane Bearings: Crane slewing bearings, hoist bearings.

Loader Bearings: Wheel hub bearings, articulated joint bearings.

Dump Truck Bearings: Axle bearings, suspension bearings.

Drilling Rig Bearings: Rotary table bearings, drill head bearings.

Conveyor Bearings: Conveyor roller bearings, pulley bearings.

Crusher Bearings: Jaw crusher bearings, cone crusher bearings.

Screen Bearings: Vibrating screen bearings, shaker bearings.

Tunneling Machine Bearings: Cutter head bearings, thrust bearings.

Excavator and Crane Slewing Bearings

A critical application in equipment like excavators and large cranes is the rotational movement of the upper structure relative to the undercarriage. This is facilitated by a slew bearing, also known as a slewing ring bearing or swing bearing.

These are large-diameter bearings, often incorporating internal or external gear teeth, designed to handle significant axial, radial, and tilting moment loads simultaneously.

The reliability of the excavator swing bearing or crane slew ring is vital for the machine’s core function, requiring robust design and manufacturing.

Heavy Equipment Track System Bearings

The undercarriage of tracked heavy equipment is subjected to some of the most punishing conditions.

Track rollers are vital components that support the massive weight of the machine and guide the track chain. These rollers rely on exceptionally durable track roller bearings. The environment is harsh, with constant exposure to abrasive dirt, water, and debris.

Therefore, heavy duty track rollers and their associated track roller wheels and track roller guide rails require bearings with superior sealing and load capacity.

TFL offers robust track roller bearing solutions, often featuring advanced sealed bearings technology.

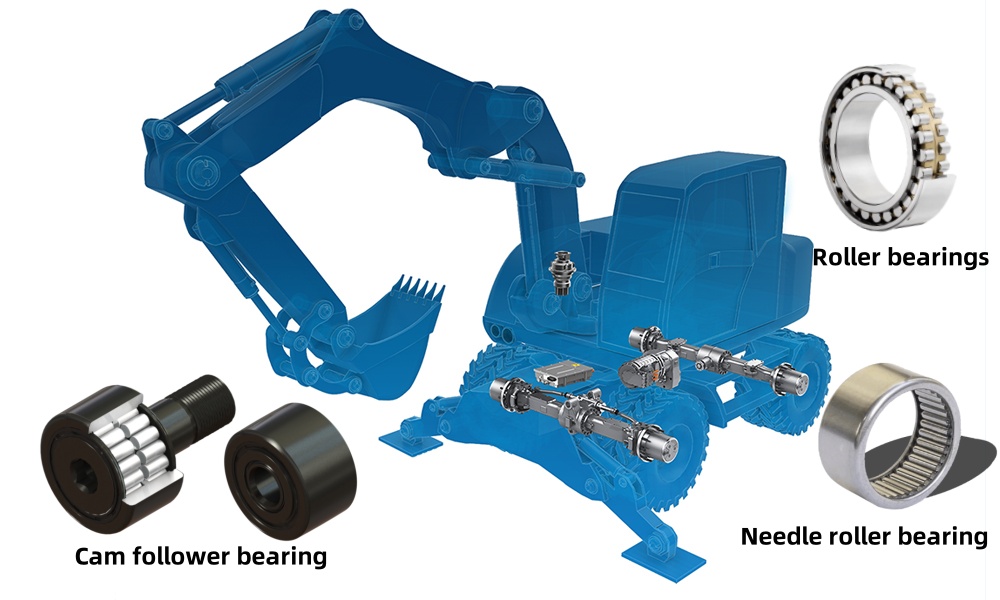

Engine Bearings and Transmission Bearings

The engines and transmissions powering heavy equipment operate under high stress and temperature. Various types of bearings are essential within these systems.

Roller bearings are frequently used for their high load capacity in crankshafts, transmission shafts, and gear sets.

Needle roller bearing assemblies are often employed where space is limited but high load capacity is still required, such as in planetary gear sets or certain valve train components.

Cam follower bearing units (or cam rollers) are crucial for translating rotary motion from camshafts (roller cam bearings) into linear motion for valve actuation, demanding durability under cyclic loading.

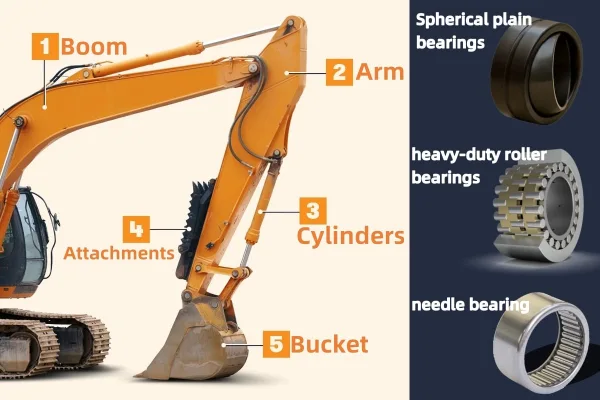

Boom and Attachment Pivot Bearings

Heavy equipment features numerous pivot points for booms, arms, buckets, and various attachments (like grapples or hammers). These joints experience high, often shock-induced loads and require durable bearings.

Spherical plain bearings, heavy-duty roller bearings, and sometimes specialized needle bearing types are used to allow smooth articulation while withstanding these forces.

Ensuring these bearings are properly sealed (sealed ball bearings or roller bearings) is critical to prevent contamination ingress, which is rampant in construction and mining environments.

FREQUENTLY ASKED QUESTIONS

What are the main challenges for bearings used in heavy equipment?

The primary challenges are extreme loads (both static and shock), heavy vibration, pervasive contamination (dirt, dust, water, chemicals), wide operating temperature ranges, and the need for very high reliability and long service life to minimize downtime. This necessitates the use of heavy duty bearings with robust sealing and materials.

Why are sealed bearings so crucial in construction and mining applications?

Sealed bearings are vital because construction and mining environments are extremely dirty and abrasive. Seals prevent contaminants like dirt, dust, grit, and moisture from entering the bearing's internal raceways and rolling elements. This contamination can rapidly degrade the bearing, leading to premature failure. Effective sealing significantly extends bearing life and equipment uptime.

What is a slew bearing and why is it important for excavators?

A slew bearing (or slewing ring bearing / swing bearing) is a large-diameter bearing that allows the upper structure of an excavator or crane to rotate 360 degrees relative to its base or undercarriage. It must handle complex combinations of axial, radial, and tilting loads simultaneously. The proper function of the excavator slew ring is fundamental to the machine's operation.

Why are needle roller bearing types sometimes preferred in certain heavy equipment applications?

Needle roller bearing assemblies offer a high load capacity within a very small radial footprint compared to other roller bearings. This makes them ideal for space-constrained locations like planetary gear sets within transmissions, universal joints in driveshafts, and certain pivot pins in attachment linkages where high strength is needed without excessive bulk.

RELATED ARTICLES

Discover the different ball bearing types like deep groove, angular contact, self-aligning, thrust, and linear. Learn their unique structures and specific uses....

Discover the unmatched advantages of super precision angular contact ball bearings that boost performance in high-demand applications. Learn more at TFL....