Automotive Bearings

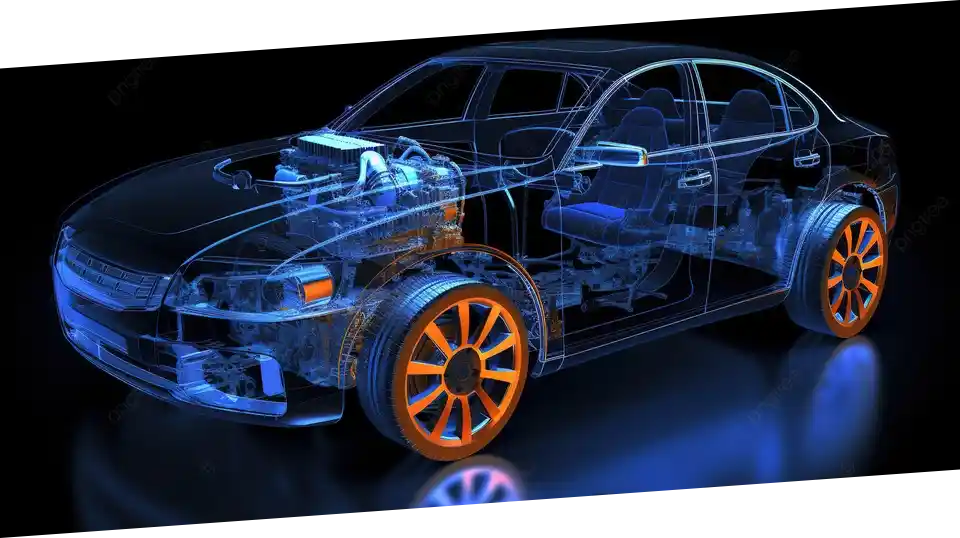

In the demanding environment of an automobile, automotive bearings must operate reliably under conditions of high vibration, extreme temperatures, varying speeds, and potential exposure to contaminants. Key applications include engines, transmissions, steering systems, and crucially, the wheel hubs which allow the vehicle to roll.

Home / Industries / Automotive Bearings

Automotive Critical Bearing Applications

Key Bearing Applications

Bearings are integrated into numerous systems throughout a vehicle. Key areas where precision bearings are essential include:

Wheel Bearings

Hub Bearings

Front Wheel Bearings

Rear Wheel Bearings

Engine Bearings

Transmission Bearings

Steering System Bearings

Accessory Component Bearings (alternator, water pump, etc.)

Wheel Assembly Bearings: Front and Rear

At the heart of a vehicle’s mobility are the wheel bearings. These components allow the wheels to rotate freely with minimal friction while supporting the weight of the vehicle and enduring significant radial and axial loads, especially during cornering.

Modern vehicles often utilize integrated wheel bearing and hub units, which combine the bearing and the wheel hub into a single, pre-assembled part, simplifying installation and improving rigidity.

Common types include tapered roller bearings and ball bearings used in hub bearing designs, depending on the load requirements.

Transmission Bearings and Powertrain Component Bearings

Bearings play a vital role in the vehicle’s transmission and driveline. These systems transmit power from the engine to the wheels. Gears rotate and mesh at high speeds, requiring bearings that can support shafts under varying loads.

Ball bearings, including deep groove ball bearing types, are widely used here. They handle both radial and thrust loads efficiently, contributing to smooth gear changes and power delivery.

Roller bearings, such as cylindrical and tapered roller bearings, are also common for higher load capacity requirements in transmissions and differentials.

Steering System and Accessory Bearings

Bearings are also crucial in steering systems and various vehicle accessories. The steering column uses bearings to allow smooth rotation. Power steering pumps and electric power steering units also contain bearings for efficient operation.

Beyond steering, components like alternators, water pumps, and air conditioning compressors utilize bearings. These are often ball bearings designed for high rotational speeds and durability. For instance, front ball bearing types might be found in smaller accessory motors or linkages.

Beyond steering, components like alternators, water pumps, and air conditioning compressors utilize bearings. These are often ball bearings designed for high rotational speeds and durability. For instance, front ball bearing types might be found in smaller accessory motors or linkages.

FREQUENTLY ASKED QUESTIONS

What does a wheel bearing do?

A wheel bearing allows your vehicle's wheels to rotate freely with minimal friction. It supports the vehicle's weight and handles forces from acceleration, braking, and cornering.

How long do wheel bearings last?

The wheel bearing life expectancy can vary significantly based on driving conditions, load, maintenance, and the quality of the bearing itself. Generally, wheel bearings lifespan ranges from 85,000 to 100,000 miles (approx. 136,000 to 160,000 kilometers), but this is just an estimate. Factors like hitting potholes, exposure to water and road salt, or improper installation can shorten their life.

What is the difference between a wheel bearing and a hub bearing?

A wheel bearing is the component that allows the wheel to spin. A hub bearing (or wheel hub bearing) is often an integrated unit that includes the bearing assembly within the wheel hub itself, simplifying installation and providing a more compact design. The terms wheel bearing wheel hub or hub bearing wheel bearing are often used interchangeably for these units.

Can you drive with a bad wheel bearing?

Driving with a bad wheel bearing is unsafe, as it can cause wheel instability, increased noise, and potential wheel detachment. Symptoms like grinding or humming indicate a bad wheel bearing. TFL recommends prompt replacement to ensure safety and avoid costly repairs.

RELATED ARTICLES

This guide outlines the critical warning signs of bearing failure, such as noise, vibration, and heat. It explains the root causes of damage and provides actionable maintenance tips to help you determine exactly when to ...

This article explores the critical role of bearing lubrication in reducing friction and preventing failure. It covers the differences between grease and oil, proper application methods, common mistakes to avoid, and main...