While the JHH series bearing is a popular standard choice for rock crushers and deep-well drilling rigs across North America, in this specific instance, it was deployed for a high-stakes tunnel excavation project. This case is an excellent example of how the right bearing material and design can solve difficult problems in the heavy industry sector.

TFL bearing solution helps tunnel boring machines operate stably

Tunnel Boring Machines (TBMs)

The tunneling industry is one of the toughest environments for machinery. Tunnel Boring Machines (TBMs) work deep underground, often cutting through solid rock and hard soil.

The “pain points” for this industry are clear:

- Extreme Contamination: The machines are surrounded by rock dust, mud, and water.

- Massive Vibration: As the machine cuts rock, the shock and vibration are constant.

- High Costs of Downtime: If a bearing fails deep inside a tunnel, replacing it is incredibly difficult and expensive. The machine cannot simply be pulled out to a garage. Reliability is the number one priority.

While the JHH series bearing is a popular standard choice for rock crushers and deep-well drilling rigs across North America, in this specific instance, it was deployed for a high-stakes tunnel excavation project. This case is an excellent example of how the right bearing material and design can solve difficult problems in the heavy industry sector.

Technical Advantages

The JHH224333-JHH224315 is not a standard bearing; it is a heavy-duty (“HH”) series bearing. Here is how its structure and materials improve performance:

-

Case-Carburized Steel (The "Hard Shell" Tech): Standard bearings are often "through-hardened," meaning they are hard all the way through. While strong, they can be brittle like glass.

- Our Solution: We use case-carburized steel. This process adds carbon to the surface, creating an ultra-hard outer "shell" that resists wear from rock dust and debris.

- The Benefit: The inside (core) remains tough and flexible. When the Tunnel Boring Machine hits hard rock and vibrates violently, the bearing absorbs the shock instead of cracking.

-

Crowned Roller Profiles (Solving Misalignment): In tunneling, the machine shafts can bend slightly under the massive weight of the earth. In a standard bearing, this causes "edge loading," where all the weight concentrates on the sharp edge of the roller, leading to rapid failure.

- Our Solution: The rollers in the JHH224333-JHH224315 feature a "crowned" or slightly curved profile.

- The Benefit: This geometry distributes the stress evenly across the center of the roller, preventing the edges from digging into the raceway, even when the machine tilts or bends slightly.

-

Advanced Rib Design for Lubrication: Friction is the enemy. The point where the roller end touches the bearing ring (the rib) is usually where the most heat is generated.

- Our Solution: The internal geometry is designed to create a "pumping action" that draws lubricant specifically to this contact area.

- The Benefit: This keeps the bearing running cooler. Lower temperatures mean the grease lasts longer and the seals stay intact, preventing water and mud from entering the system.

-

Heavy-Duty Steel Cages: The cage (or retainer) keeps the rollers separated. In high-vibration environments like drilling, weak cages are the first thing to break.

- Our Solution: This model utilizes a stamped steel cage that wraps around the rollers, providing maximum stability.

- The Benefit: It ensures the rollers stay in the correct position during heavy digging, preventing the internal jamming that destroys gearboxes.

The TFL Solution

For this project, the customer required a high-performance replacement for the main drive system of their equipment. The specific model chosen was the JHH224333-JHH224315.

Application Location: This heavy-duty Tapered Roller Bearing is typically found in the main gearboxes or cutterhead support systems of excavation equipment. It sits where the stress is highest, connecting the moving parts that crush the rock to the main body of the machine.

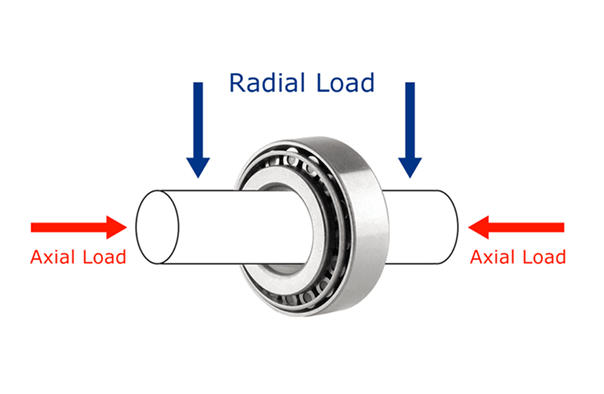

Why Tapered Roller Bearings? Tapered roller bearings are designed perfectly for this work because they handle combined loads.

- Radial Load: The heavy weight of the machine parts pressing down.

- Axial Load: The massive force of the machine pushing forward into the tunnel wall.

Comparison: Standard vs. Premium Application

| Feature | Standard Bearing | Our Premium Solution (JHH Series) |

| Load Capacity | Moderate | Extra Heavy (HH) for extreme pressure |

| Shock Resistance | Can crack under impact | Case-hardened core absorbs shock |

| Life Expectancy | Average | Extended, reducing maintenance trips |

| Heat Generation | High | Low, due to superior surface finish |

Conclusion

By choosing the correct specification—the JHH224333-JHH224315—our US client was able to ensure their tunneling equipment continued to operate smoothly without unexpected stops. In the tunneling business, using the right bearing material and structure isn’t just an upgrade; it is an insurance policy for the entire project.

About TFL BEARINGS

Why is TFL BEARINGS frequently chosen as the specified bearing brand bymajor international companies?

Reliable Operation Starts Here

Contact TFL Bearings for the Best Solutions!

Our efficient global supply chain and inventory management ensure fast response and timely delivery.

We tailor bearing solutions to unique needs. Services include design advice & custom specifications for your specific application.

Competitive prices. Quality bearings meet int'l stds; interchangeable. Reliable, economical alternative. Lower costs, keep performance & value.

Quality products plus reliable full service. Our pro team offers support from selection to after-sales. We aim to be your trusted partner.